High-selectivity polyamide nanofiltration membrane and preparation method thereof

A high-selectivity, polyamide technology, applied in the field of membrane separation, can solve the problems of low selectivity and insufficient water flux, and achieve the effect of simple preparation process and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

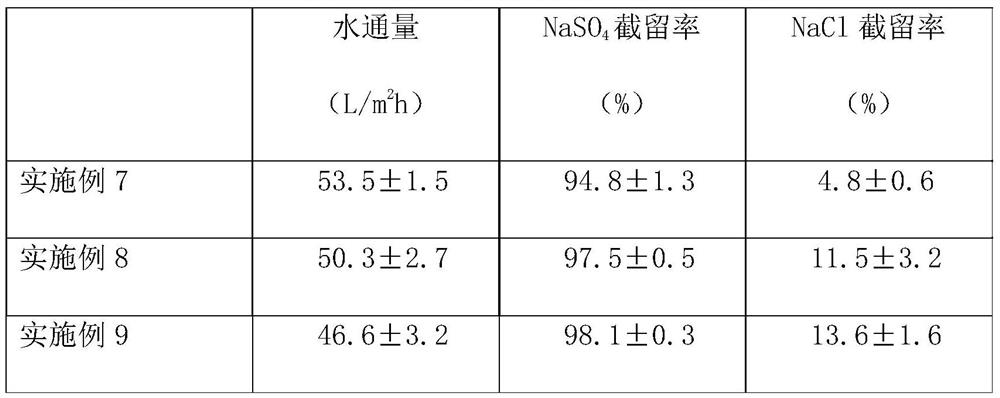

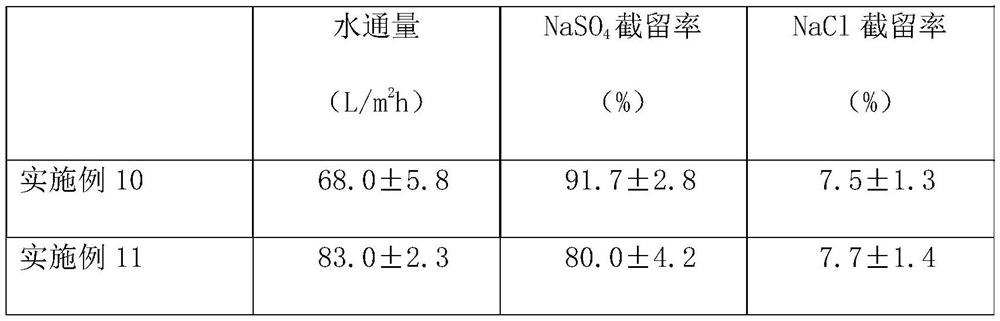

Examples

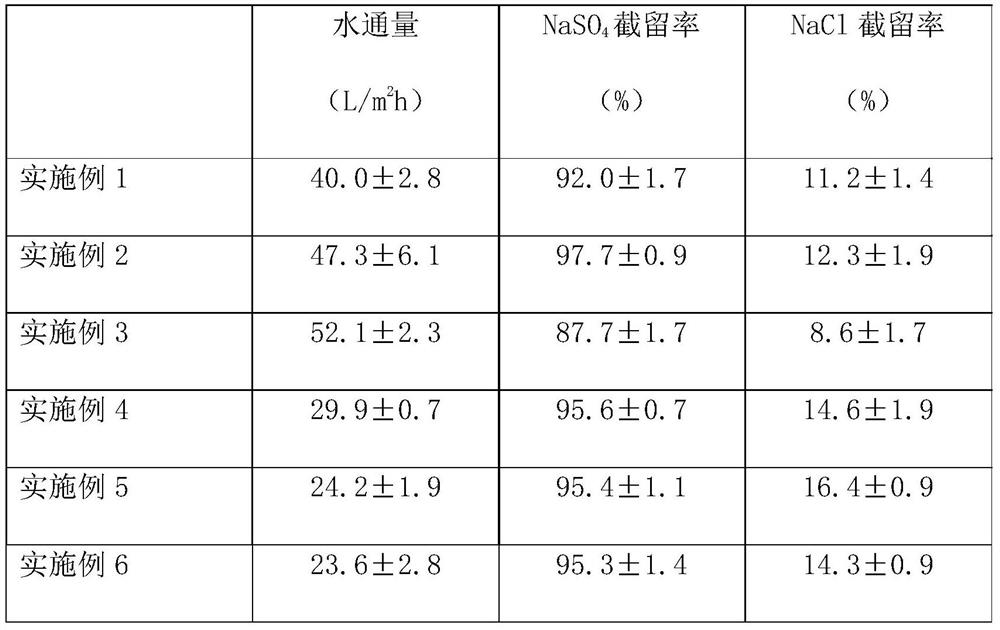

Embodiment 1

[0036] A 1,4-diazepane aqueous phase solution with a concentration of 0.3% (w / v) and a trimesoyl chloride n-hexane solution with a concentration of 0.3% (w / v) were prepared. Introduce the water phase solution into the inner cavity of the hollow fiber membrane. The coating time of the water phase solution is 5 minutes. Slowly put the hollow membrane module into the organic phase solution to react for 2 minutes. The temperature of the organic phase is 25°C. .

Embodiment 2

[0038] A 1,4-diazepane aqueous phase solution with a concentration of 0.3% (w / v) and a trimesoyl chloride n-hexane solution with a concentration of 0.3% (w / v) were prepared. Introduce the water phase solution into the inner cavity of the hollow fiber membrane. The coating time of the water phase solution is 5 minutes. Slowly put the hollow membrane module into the organic phase solution to react for 2 minutes. The temperature of the organic phase is 25°C. .

Embodiment 3

[0040] A 1,4-diazepane aqueous phase solution with a concentration of 0.1% (w / v) and a trimesoyl chloride n-hexane solution with a concentration of 0.3% (w / v) were prepared. Introduce the water phase solution into the inner cavity of the hollow fiber membrane. The coating time of the water phase solution is 5 minutes. Slowly put the hollow membrane module into the organic phase solution to react for 2 minutes. The temperature of the organic phase is 25°C. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com