Preparation method of ZIF-8@g-C3N4 catalyst with zeolite structure

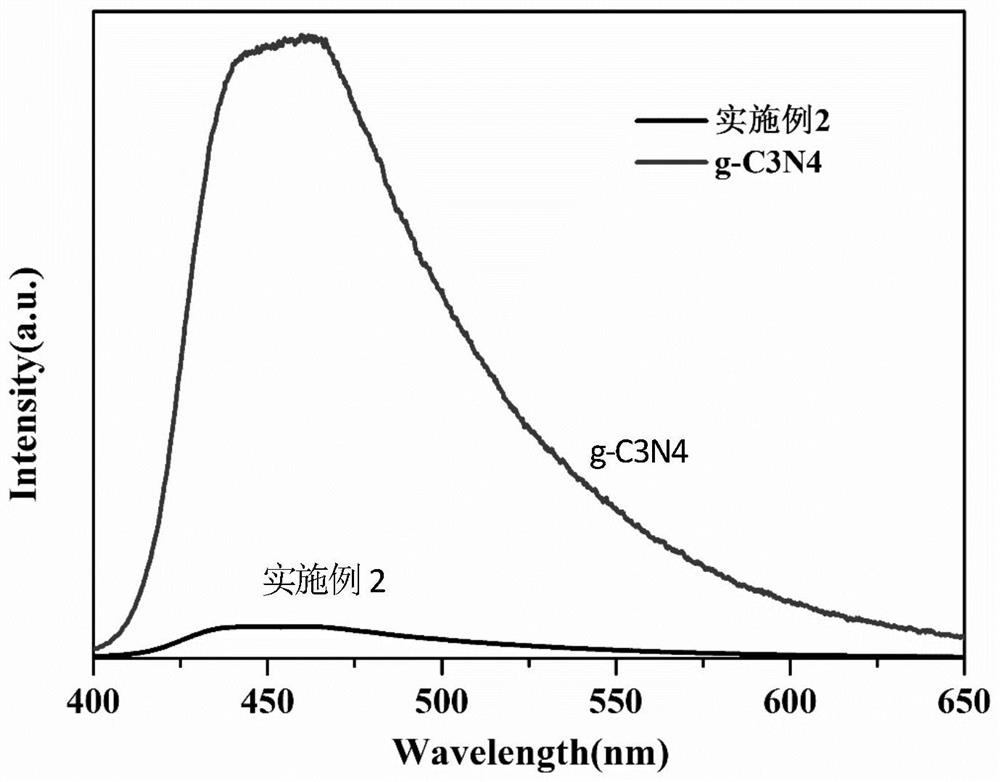

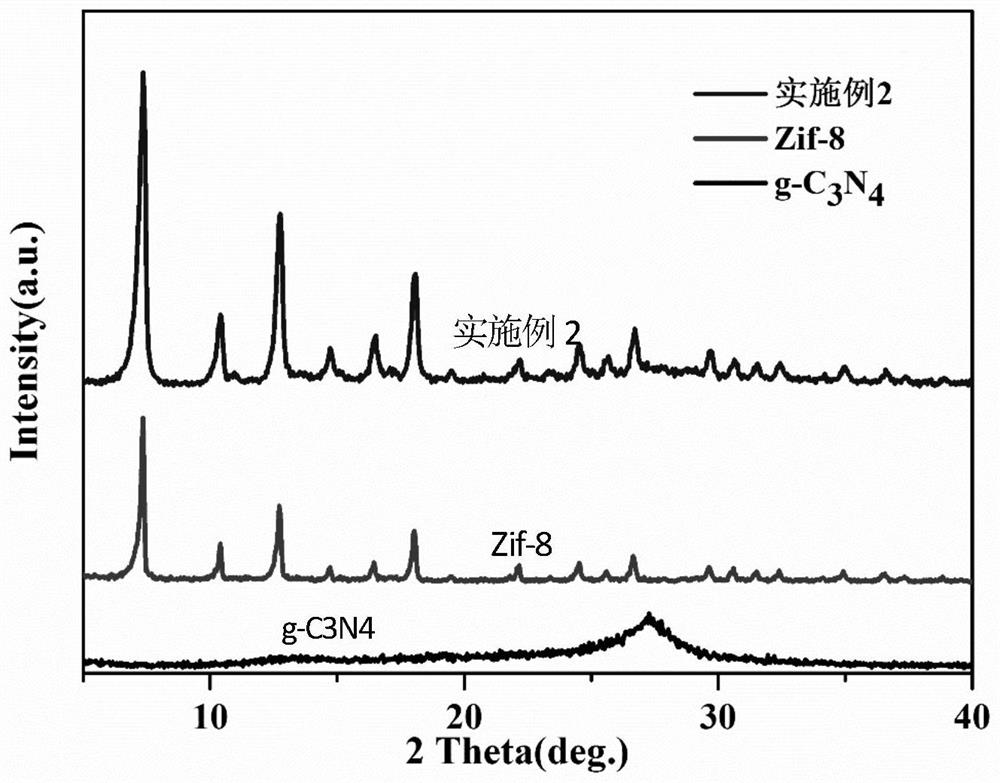

A ZIF-8, g-c3n4 technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve the problem of low utilization of sunlight and visible light catalysts. The problem of poor catalytic effect, etc., achieves the effect of high carrier separation efficiency, easy large-scale production, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1) Weigh 50g of urea and grind it evenly.

[0041] 2) Transfer (1) to an alumina crucible with a cover, and roast it in a muffle furnace at 475°C for 4 hours in an air atmosphere, with a heating rate of 4°C / min, and then cool to room temperature to obtain a yellow powder that is a layered g -C3N4.

[0042] 3) Weigh barbitic acid, zinc nitrate, dimethylimidazole and g-C3N4 respectively according to the mass ratio of 0.2:1:2:1, disperse g-C3N4 in 40ml of methanol solution, sonicate for 0.5h, and then Barbic acid was added to the mixture and stirred for 0.5h.

[0043] 4) Dissolve zinc nitrate in (3) and continue stirring for 1 h. At the same time, dimethylimidazole was dissolved in 40ml of methanol solution and stirred for 1h.

[0044] 5) Add the dimethylimidazole solution dropwise into the mixed solution of g-C3N4, barbic acid and zinc nitrate under stirring condition, then stir at room temperature for 1 h, and let stand for 3 h.

[0045] 6) Centrifuge, wash repeatedl...

Embodiment 2

[0048] 1) Weigh 50g of urea and grind it evenly.

[0049] 2) Transfer (1) to an alumina crucible with a cover, and bake in a muffle furnace at 500°C for 3h in an air atmosphere, with a heating rate of 3°C / min, and then cool to room temperature to obtain a yellow powder that is a layered g -C3N4.

[0050] 3) Weigh barbitic acid, zinc nitrate, dimethylimidazole and g-C3N4 respectively according to the mass ratio of 0.2:1:2:2.5, disperse g-C3N4 in 40ml of methanol solution, sonicate for 0.75h, and then Barbic acid was added to the mixture and stirred for 1h.

[0051] 4) Dissolve zinc nitrate in (3) and continue stirring for 1 h. At the same time, dimethylimidazole was dissolved in 40ml of methanol solution and stirred for 1h.

[0052] 5) Add the dimethylimidazole solution dropwise into the mixed solution of g-C3N4, barbic acid and zinc nitrate under the condition of stirring, then stir at room temperature for 1 h, and let stand for 5 h.

[0053] 6) Centrifuge, wash repeatedly...

Embodiment 3

[0056] 1) Weigh 50g of urea and grind it evenly.

[0057] 2) Transfer (1) to an alumina crucible with a cover, and bake in a muffle furnace at 550°C for 4h under an air atmosphere, with a heating rate of 4°C / min, and then cool to room temperature to obtain a yellow powder that is a layered g -C3N4.

[0058] 3) Weigh barbitic acid, zinc nitrate, dimethylimidazole and g-C3N4 respectively according to the mass ratio of 0.2:1:2:5, disperse g-C3N4 in 40ml of methanol solution, sonicate for 1h, and then Add more than acid to the mixture and stir for 2h.

[0059] 4) Dissolve zinc nitrate in (3) and continue stirring for 2h. At the same time, dimethylimidazole was dissolved in 40ml of methanol solution and stirred for 2h.

[0060] 5) Add the dimethylimidazole solution dropwise into the mixed solution of g-C3N4, barbic acid and zinc nitrate under stirring condition, then stir at room temperature for 2h, and let stand for 8h.

[0061] 6) Centrifuge, wash repeatedly with methanol and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com