A magnetic zif-8 coated fe 3 o 4 /g-c 3 no 4 Composite catalyst, preparation method and application

A technology of ZIF-8 and composite catalysts, which is applied in physical/chemical process catalysts, chemical instruments and methods, water/sludge/sewage treatment, etc. It can solve the problems of low utilization rate of sunlight and poor catalytic effect of visible light catalysts, etc. problem, to achieve the effect of wide spectral response range, excellent visible light catalytic effect, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

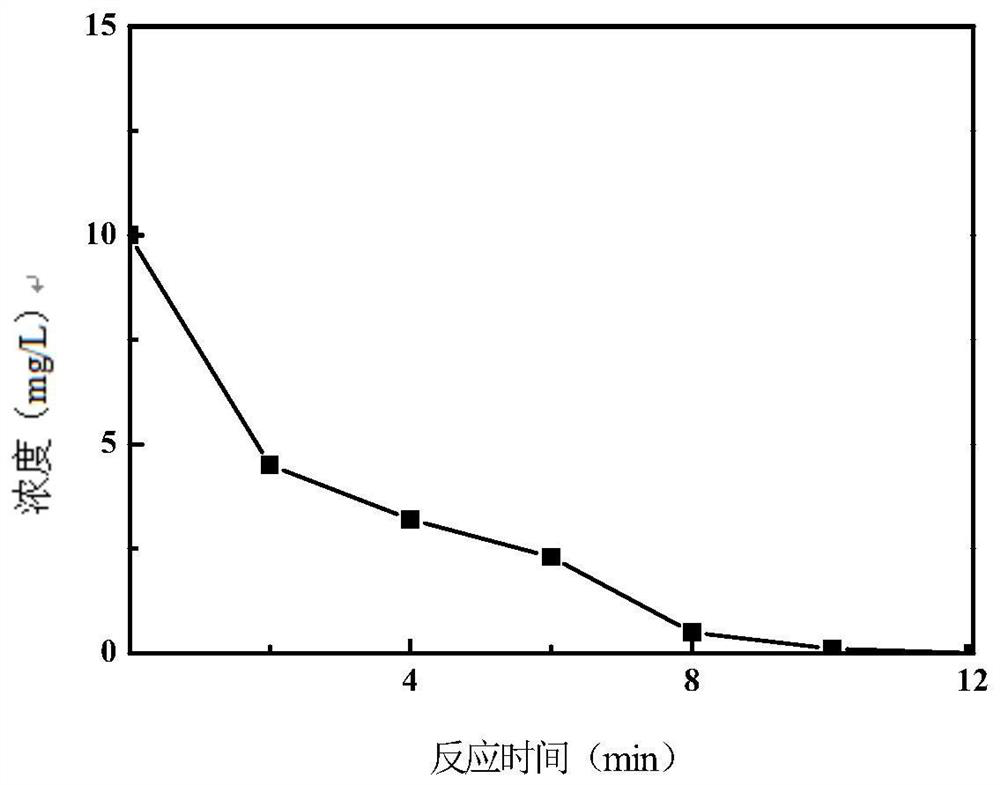

Embodiment 1

[0045] (1) Preparation of ZIF-8 Porous Matrix

[0046] According to the mass ratio of 1:2 zinc nitrate and dimethylimidazole were weighed, dispersed into methanol solution, ultrasonically treated for 1 h, then left to stand for 12 h, filtered, washed and dried to obtain ZIF-8 porous matrix material.

[0047] (2) ZIF-8 surface modification

[0048] The ZIF-8 obtained in step (1) and the sodium lignosulfonate are ground and mixed in a mortar according to the mass ratio of 1:5, washed with ethanol, filtered and dried to obtain the surface-modified ZIF-8 to ensure the iron in the later stage. Ions and urea only enter into the pores of ZIF-8, so they will not be adsorbed on its surface.

[0049] (3) Solution filling of ZIF-8

[0050] ZIF-8 is immersed in the mixed solution of ferric nitrate and urea after the modification of step (2) for 24h, and is immersed again after filtering every 6 hours, wherein product (2): the mass ratio of ferric nitrate and urea is controlled at 1:1:5...

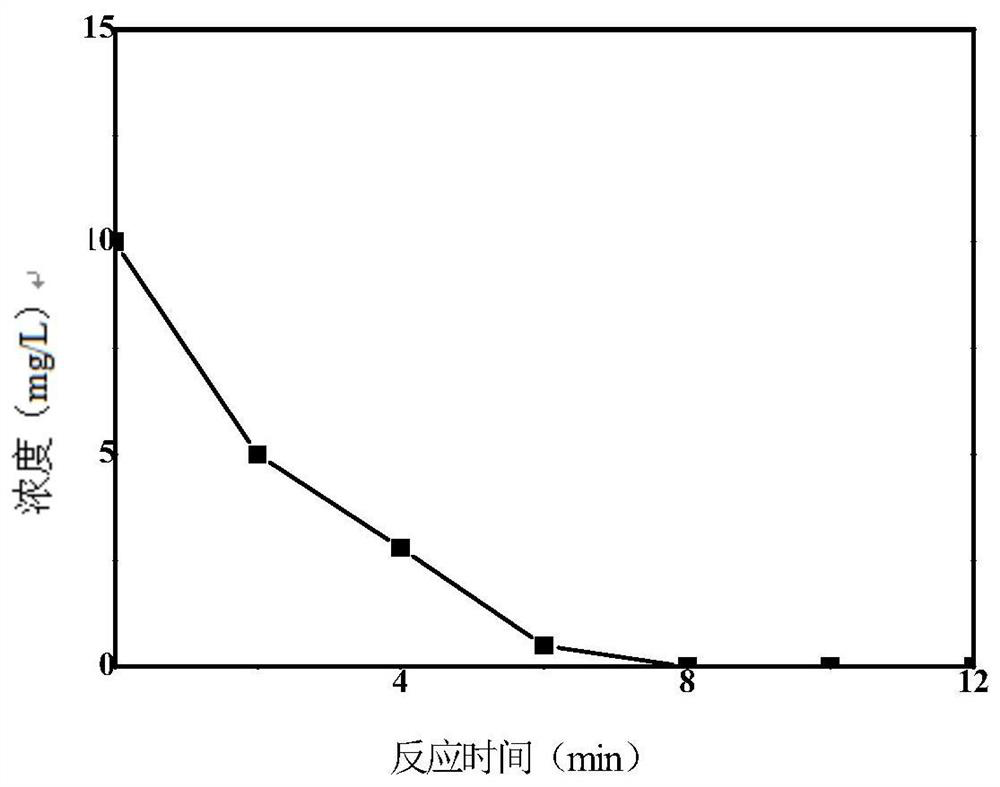

Embodiment 2

[0057] (1) Preparation of ZIF-8 Porous Matrix

[0058] According to the mass ratio of 1:2 zinc nitrate and dimethylimidazole were weighed, dispersed into methanol solution, ultrasonically treated for 1 h, then left to stand for 10 h, filtered, washed and dried to obtain ZIF-8 porous matrix material.

[0059] (2) ZIF-8 surface modification

[0060] The ZIF-8 obtained in step (1) and the sodium lignosulfonate are ground and mixed in a mortar according to the mass ratio of 1:10, washed with ethanol, filtered and dried to obtain the surface-modified ZIF-8 to ensure the iron in the later stage. Ions and urea only enter into the pores of ZIF-8, so they will not be adsorbed on its surface.

[0061] (3) Solution filling of ZIF-8

[0062] ZIF-8 after step (2) gained modification is immersed in the mixed solution of ferric nitrate and urea for 48h, re-dipping after filtering every 6 hours, wherein product (2): the mass ratio of ferric nitrate and urea is controlled at 1:1:10 range. ...

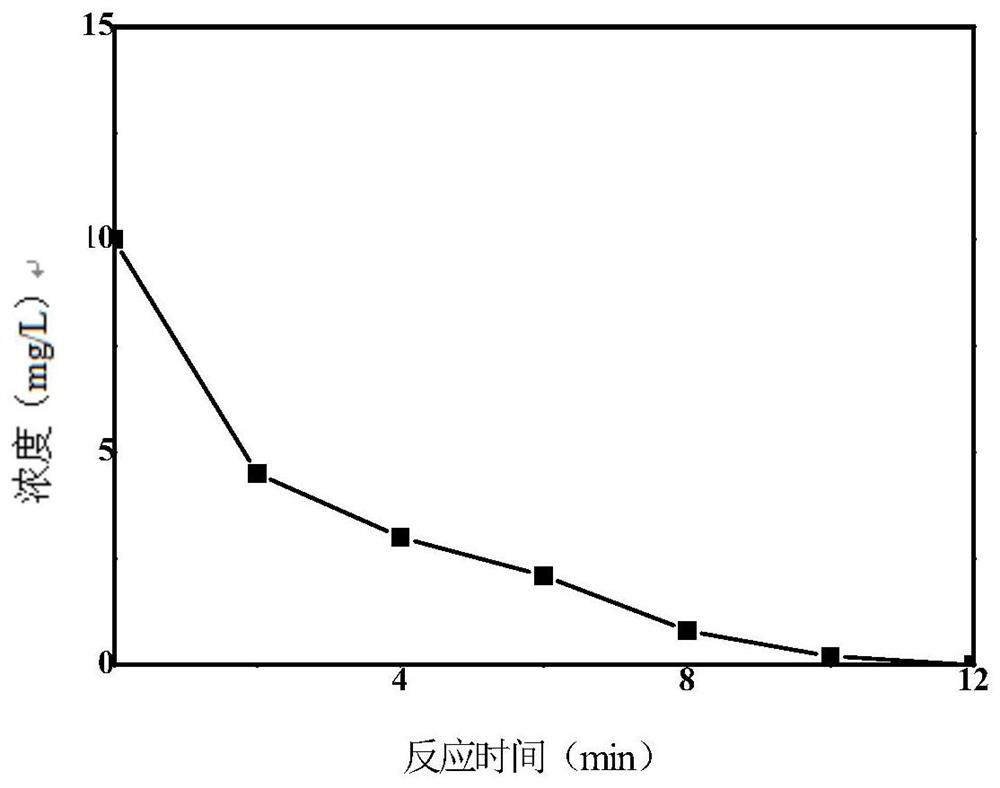

Embodiment 3

[0069] (1) Preparation of ZIF-8 Porous Matrix

[0070] According to the mass ratio of 1:2 zinc nitrate and dimethylimidazole were weighed, dispersed into methanol solution, ultrasonically treated for 1 h, then left to stand for 12 h, filtered, washed and dried to obtain ZIF-8 porous matrix material.

[0071] (2) ZIF-8 surface modification

[0072] The ZIF-8 obtained in step (1) and the sodium lignosulfonate are ground and mixed in a mortar according to the mass ratio of 1:10, washed with ethanol, filtered and dried to obtain the surface-modified ZIF-8 to ensure the iron in the later stage. Ions and urea only enter into the pores of ZIF-8, so they will not be adsorbed on its surface.

[0073] (3) Solution filling of ZIF-8

[0074] ZIF-8 after the gained modification of step (2) is immersed in the mixed solution of ferric nitrate and urea for 24h, and is immersed again after filtering every 6 hours, wherein the mass ratio of product (2) ferric nitrate and urea is controlled at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com