Sludge low-temperature carbonization system

A carbonization system and sludge technology, applied in pyrolysis treatment of sludge, dewatering/drying/concentrated sludge treatment, etc., can solve the problems of unstandardized treatment of sludge, threats to the ecological environment, and backward disposal methods, etc. Thorough and efficient treatment, low cost, and the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

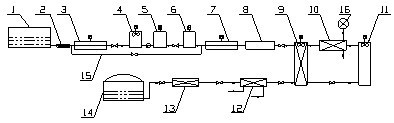

[0016] like figure 1 As shown, a sludge low-temperature carbonization system adopts a new treatment method to avoid environmental pollution and protect the ecological environment. The sludge low-temperature carbonization system uses low-temperature, medium-high pressure parameters to lyse the cells in the sludge, The final sludge changes from the original semi-solid state to a liquid state, and the water is easy to escape, so that the moisture content of the sludge is reduced to below 50%. After dewatering, the sludge looks like sand and is easy to dry. Forced air drying can further reduce the moisture content to below 30%, and natural air drying (3-5 days) can reach below 10%. The use of this system has effectively improved The overall efficiency of the treatment and the overall safety in the treatment process are better, which can ensure a more thorough and efficient treatment of the sludge. The cost of the overall treatment system is lower when it is used, and it does not n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com