Wholly aromatic polyamide fiber

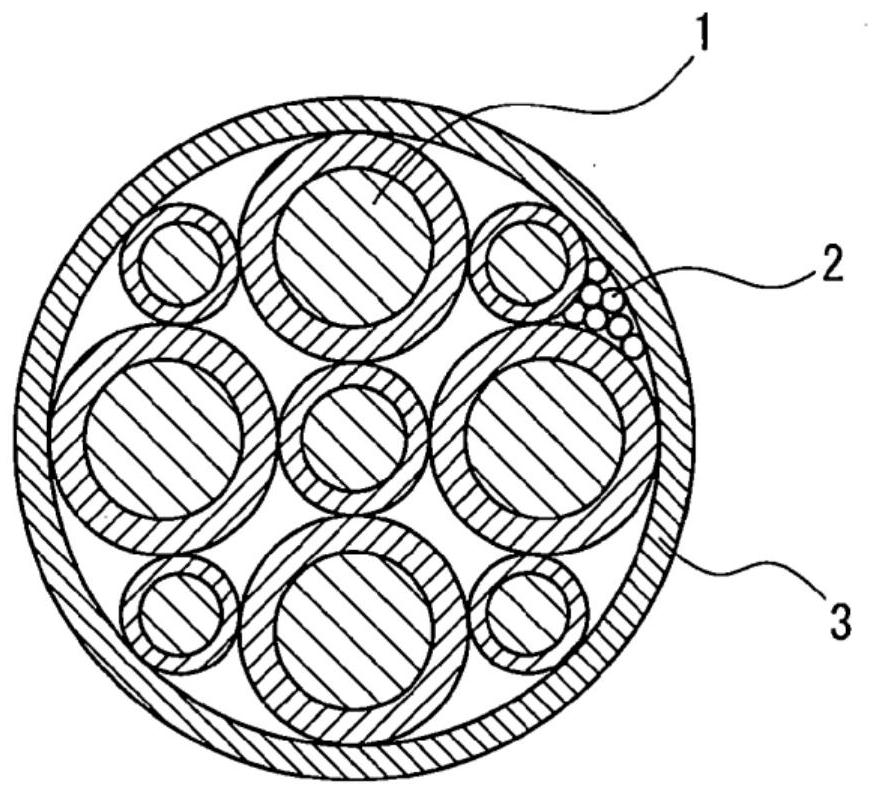

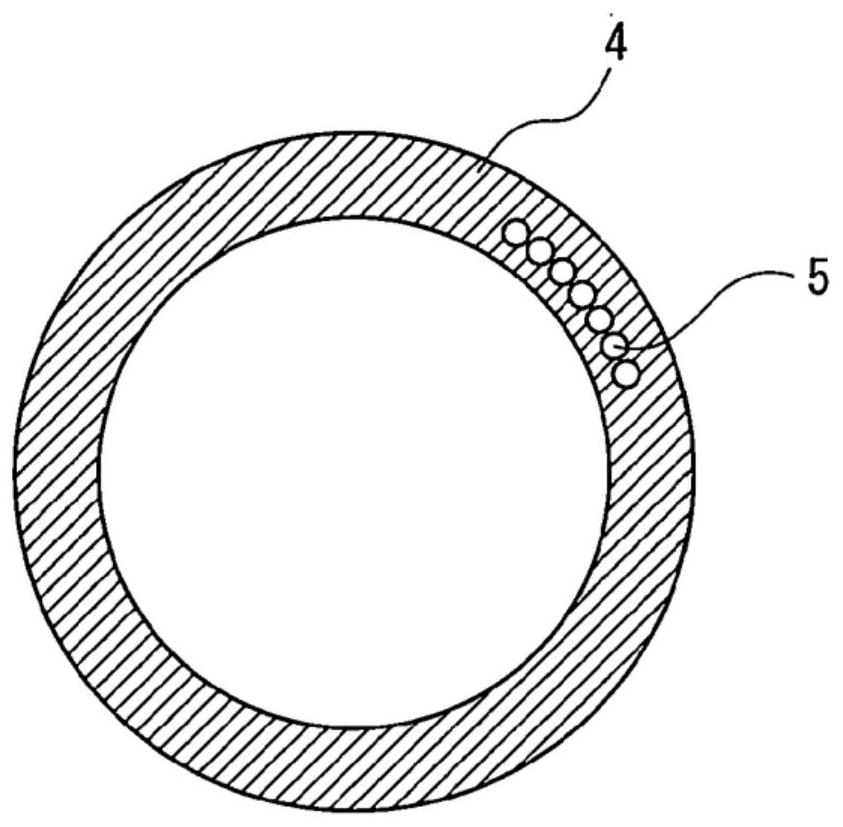

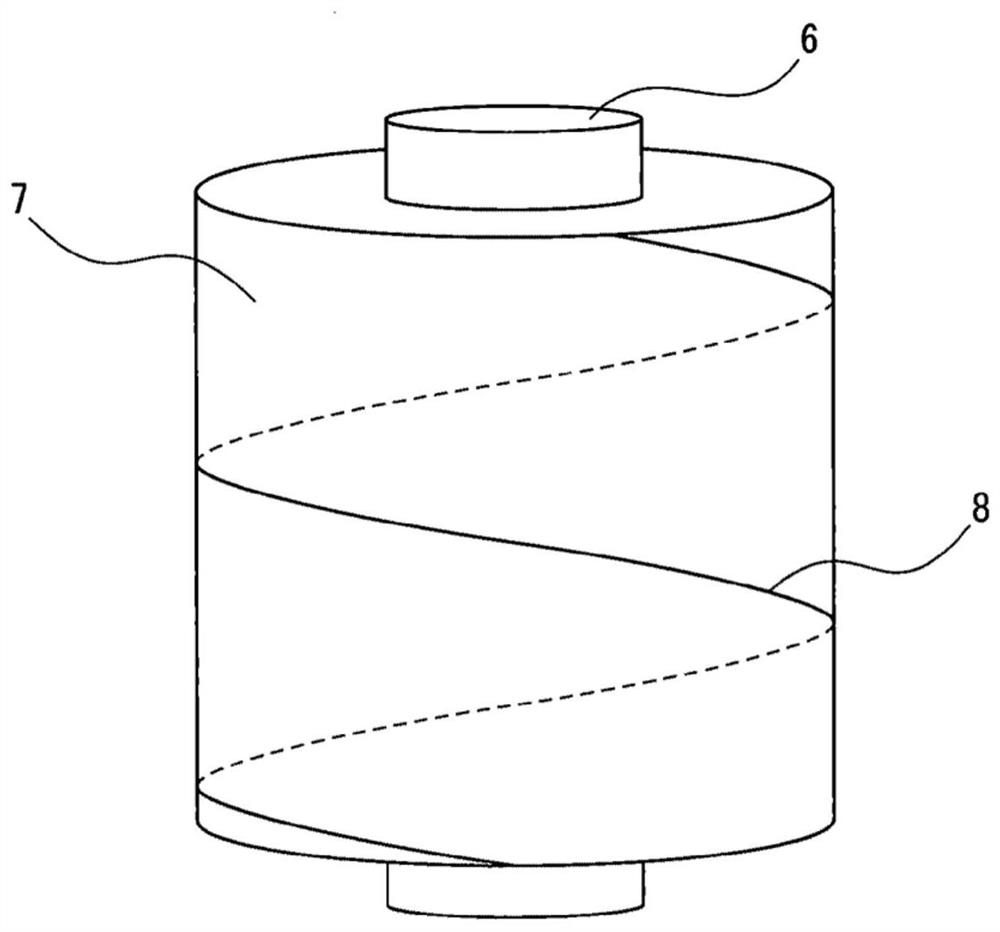

A polyamide fiber, fully aromatic technology, used in the field of composite cables and conduits, can solve the problems of kink, no flexibility, large thickness, etc., and achieve fine single filament fineness, fine total fineness, excellent quality and reinforcement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0083] Examples of solvents used in the preparation of the spinning solution (dope) include N-methylpyrrolidone (NMP), dimethylacetamide (DMAc), dimethylformamide (DMF), dimethylmethylene Sulfone (DMSO) and N-methylcaprolactam (NMC), etc. The solvent to be used may be alone or may be a mixed solvent obtained by mixing two or more kinds. Furthermore, the solvent used for the polymerization of a wholly aromatic polyamide can also be used as it is.

[0084] In addition, other optional components such as additives may be blended for the purpose of imparting functionality to the fibers. Other optional components may be introduced during the preparation of the spinning solution (dope). The introduction method is not particularly limited, and for example, the coating material can be introduced using an extruder, a mixer, or the like.

[0085] It should be noted that the polymer concentration in the spinning solution (dope), that is, the concentration of the wholly aromatic polyami...

Embodiment 1

[0194] (Preparation of paint)

[0195] A polymer solution (dope) of copolymerized p-phenylene-3,4'-oxydiphenylene-terephthalamide was prepared according to a known method. Specifically, 100 parts by mass of terephthaloyl dichloride was added to NMP in which 50 parts by mass of p-phenylenediamine and 50 parts by mass of 3,4'-diaminodiphenyl ether were dissolved, and a polycondensation reaction was carried out to obtain a copolymer Polymer solutions (paints) of p-phenylene-3,4'-oxydiphenylene-terephthalamide. The polymer concentration was 6% by mass. The intrinsic viscosity (IV) of the polymer was 3.38.

[0196] (Manufacture of fully aromatic polyamide fiber)

[0197] The polymer solution (dope) obtained above was discharged using a spinning spinneret having 8 holes. Then, the spun polymer solution (dope) was passed through a coagulation bath through an air gap of 10 mm, thereby being coagulated. The coagulation bath was set at 60° C. and filled with an aqueous solution hav...

Embodiment 2

[0201] Using a spinning spinneret with 10 holes, discharging in a manner that the total fineness becomes 28dtex, and setting the number of filaments to 10, and the single filament fineness to 2.8dtex, except that, the same method as in Example 1 was used to obtain the full Aramid fiber. Table 1 shows the physical properties and the like of the obtained wholly aromatic polyamide fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com