Polyamide nanofiltration membrane as well as preparation method and application thereof

A technology of polyamide-based membranes and activated polyamide-based membranes, applied in the field of separation membranes, can solve problems such as the decline in the rejection rate of small organic molecules, irreversible pollution, etc., achieve excellent chemical cleaning stability, excellent alkali swelling resistance, and improve separation selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

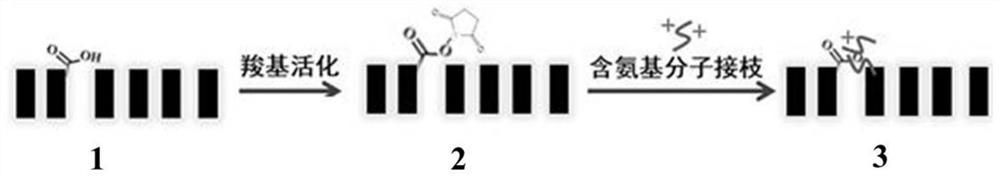

Method used

Image

Examples

Embodiment 1

[0060] A kind of preparation method of polyamide nanofiltration membrane, concrete steps are as follows:

[0061] (1) XN45 (Trisep TM ) The polyamide-based membrane is placed in an aqueous sodium hydroxide solution with a pH value of 11 and treated at 30° C. for 1 hour, and washed to obtain a pretreated polyamide-based membrane;

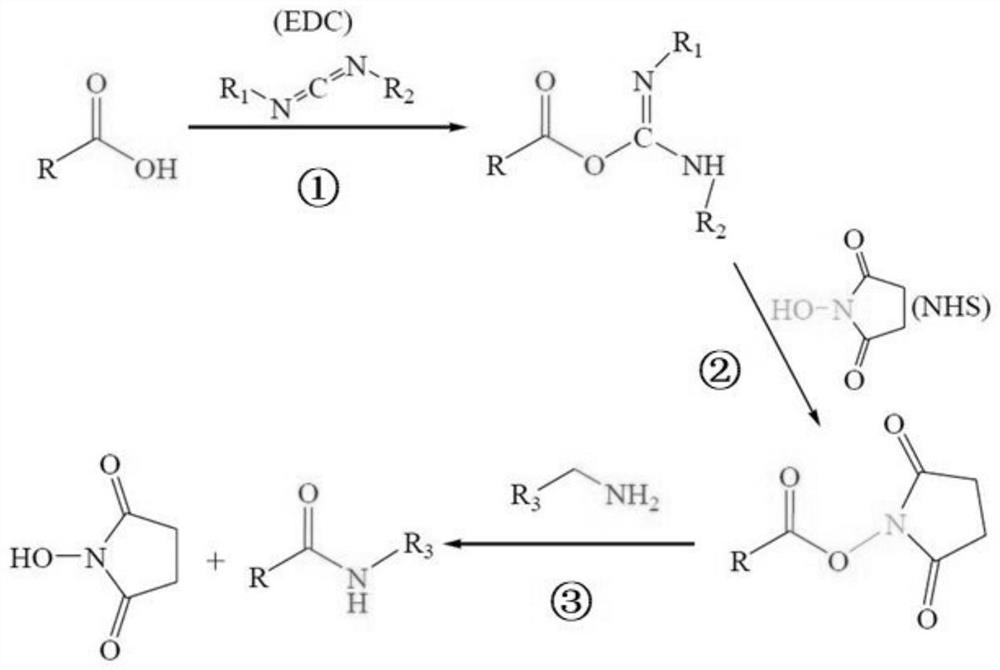

[0062] (2) Place the pretreated polyamide-based membrane obtained in step (1) in the MES buffer (0.1M, pH=5) of EDC and NHS for 1h at 37°C; wherein, the mass concentration of EDC in the MES buffer solution is 0.5g / L, the mass concentration of NHS is 0.8g / L, and the activated polyamide-based membrane is obtained;

[0063] (3) Treat the activated polyamide-based membrane obtained in step (2) in a phosphoric acid (PBS) buffer (0.1M, pH=6) with a molecular weight of 1800Da polyethyleneimine for 1 hour at 37°C, wherein the polyamide in the PBS buffer The mass concentration of ethyleneimine is 0.4g / L, and the polyamide nanofiltration membrane is obtained...

Embodiment 2

[0065] A kind of preparation method of polyamide nanofiltration membrane, concrete steps are as follows:

[0066] (1) Place the NF270 polyamide-based membrane with a molecular weight cut-off of 200Da in an aqueous sodium hydroxide solution with a pH value of 11.5 and treat it at 25° C. for 1 hour, and then wash to obtain a pretreated polyamide-based membrane;

[0067] (2) Place the pretreated polyamide-based membrane obtained in step (1) in the MES buffer (0.1M, pH=5) of EDC and NHS for 1h at 37°C; wherein, the mass concentration of EDC in the MES buffer solution is 0.4g / L, the mass concentration of NHS is 0.6g / L, and the activated polyamide-based membrane is obtained;

[0068] (3) Treat the activated polyamide-based membrane obtained in step (2) in a phosphoric acid (PBS) buffer (0.1M, pH=6) with a molecular weight of 600Da polyethyleneimine for 2 hours at 37°C, wherein the polyamide in the PBS buffer The mass concentration of ethyleneimine is 0.3g / L, and the polyamide nanof...

Embodiment 3

[0070] A kind of preparation method of polyamide nanofiltration membrane, concrete steps are as follows:

[0071] (1) The XN45 polyamide-based membrane with a molecular weight cut-off of 300Da was placed in an aqueous sodium hydroxide solution with a pH value of 10.5 and treated at 35° C. for 1 hour, and washed to obtain a pretreated polyamide-based membrane;

[0072] (2) Place the pretreated polyamide-based membrane obtained in step (1) in the MES buffer (0.1M, pH=5) of EDC and NHS for 2h at 37°C; wherein, the mass concentration of EDC in the MES buffer solution is 0.5g / L, the mass concentration of NHS is 0.8g / L, and the activated polyamide-based membrane is obtained;

[0073] (3) Treat the activated polyamide-based membrane obtained in step (2) in chitosan phosphoric acid (PBS) buffer (0.1M, pH=6) at 37°C for 2h, wherein the mass of chitosan in PBS buffer The concentration is 0.3g / L, and the polyamide nanofiltration membrane is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com