Battery crushing and sorting treatment process and treatment equipment thereof

A technology for processing equipment and batteries, which is applied in grain processing, battery recycling, and solid separation. It can solve the problems of inability to effectively separate copper, aluminum, positive and negative electrode powders, large fluctuations, and difficulty in ensuring purity, and achieve separation High effect, improved recovery rate, and reduced adhesion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

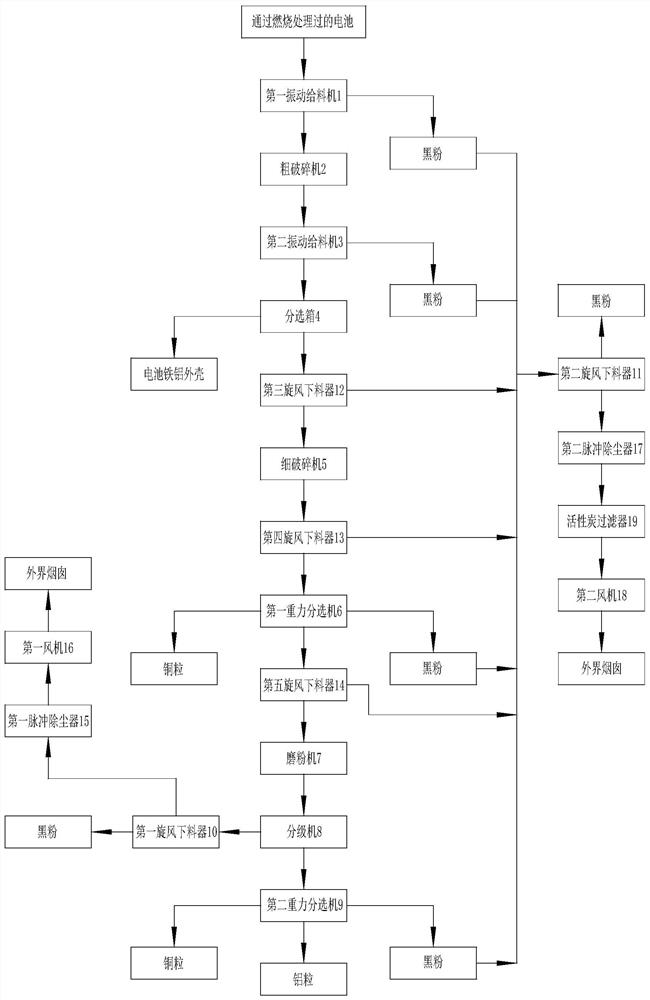

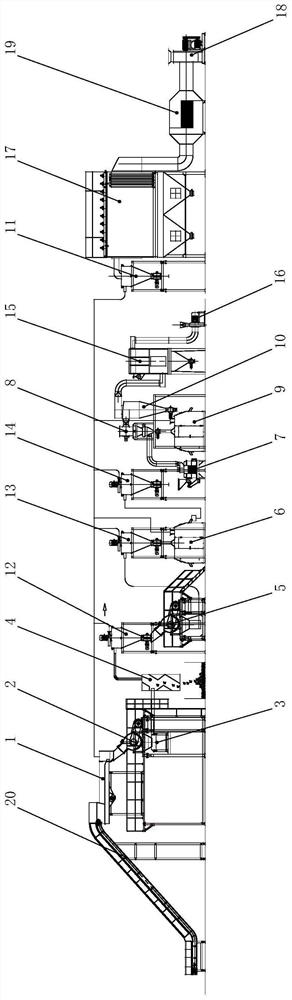

[0030]The present invention will be further described below with specific examples, seefigure 1 -2:

[0031]In the present invention, there is no separator paper in the battery waste after combustion treatment.

[0032]A treatment process for battery crushing and sorting includes the following steps:

[0033](1) The first vibration transportation: place the burned battery waste in a vibrating feeder and forward it to the coarse crusher, and during the transportation process, the black powder that is vibrated from the battery waste is sucked in by negative pressure Recycle in the cyclone feeder;

[0034](2) Coarse crushing of battery waste: the battery waste is roughly crushed by a coarse crusher, and the size of the battery waste after coarse crushing is 2-3 cm;

[0035](3) The second vibration transportation: the coarsely crushed battery waste is placed in a vibrating feeder and forwarded to the sorting box, and during the transportation process, the black powder vibrated from the battery waste i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com