Preparation process of wear-resistant rubber material

A wear-resistant rubber and preparation technology, which is applied in the direction of mixer, transportation, packaging, dissolution, etc., can solve the problems of the reduction of the reinforcement performance of rubber materials, the wear resistance of fatigue wear materials, and the impact of filler dispersion, so as to achieve the goal of not being easy to agglomerate, Improved compatibility and uniform performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

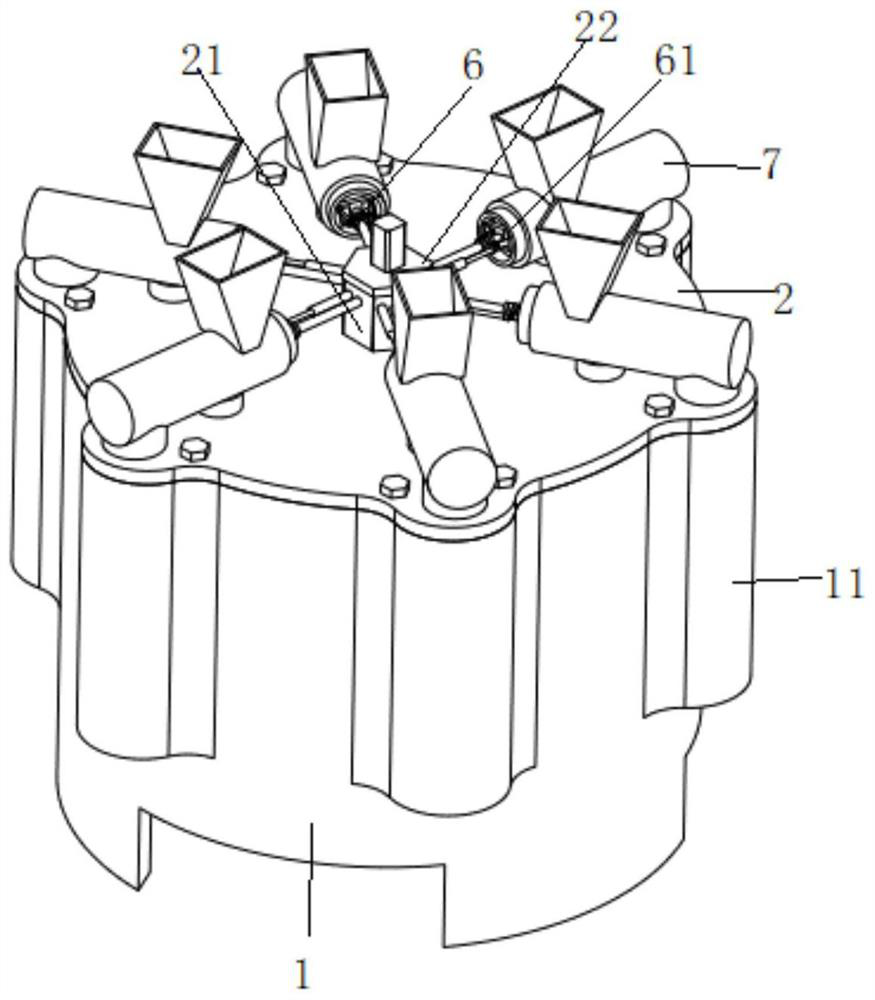

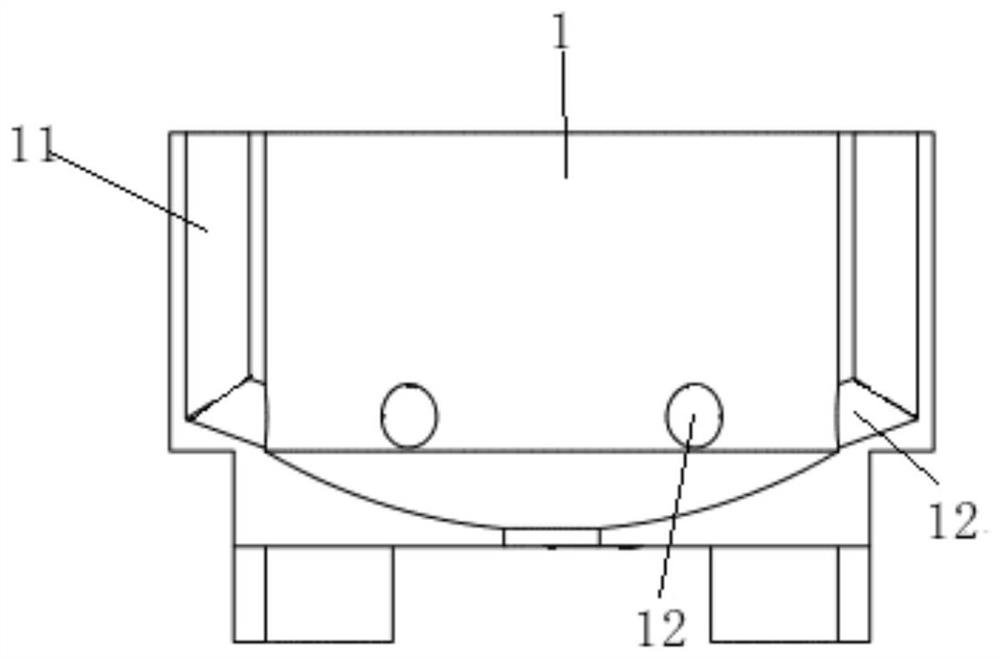

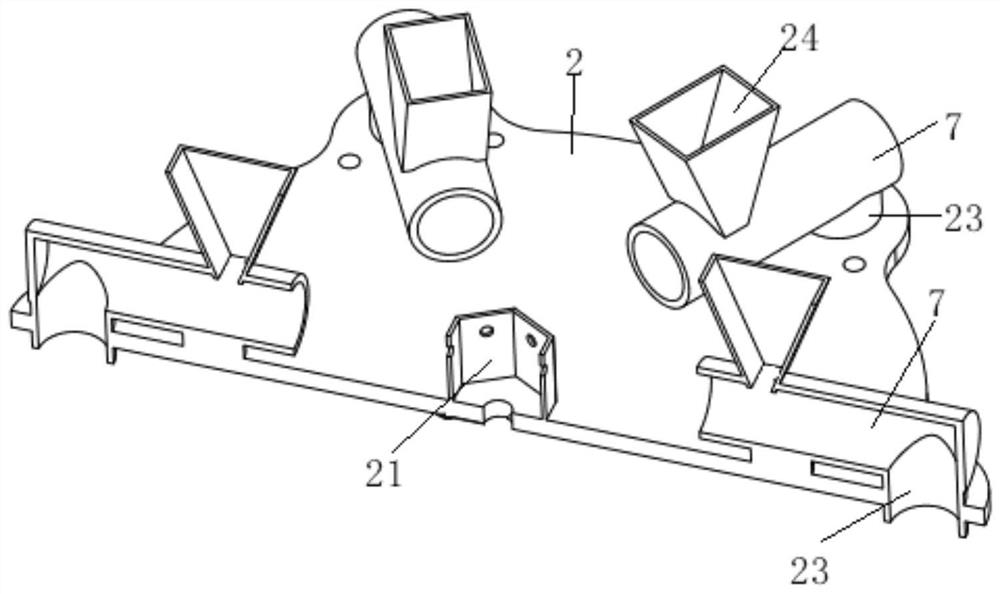

[0027] In the preparation process of rubber materials, in order to improve its wear resistance, it is necessary to add modified wear-resistant fillers. In the preparation process of modified wear-resistant fillers, the present invention provides a split-feeding reactor in order to realize sufficient modification of fillers. The sub-feeding reactor includes a reaction tank 1, a top cover 2 is fixed on the top of the reaction tank 1, a first rotating shaft 3 is installed at the center of the surface of the installation top cover 2, and a crushing and stirring mechanism 4 is installed at the bottom of the first rotating shaft 3 , the top end is connected with the power output end of the first reduction motor, and the center of the surface where the top cover 2 is installed is integrally connected and fixed with a fixed cylinder 21. The interior of the fixed cylinder 21 is equipped with a multi-directional transmission mechanism 5, and the multi-directional transmission mechanism 5 ...

Embodiment 2

[0041] The preparation method of the organic carbon material is the same as in Example 1. According to the amount added in Example 1, the organic carbon material, diatomaceous earth and nano-alumina are added to the reaction kettle at the same time, and then deionized water is added thereto, and the silane distillate is added after stirring evenly. The joint agent kh-560 was stirred and mixed for 3 hours, and then the obtained material was filtered, washed and dried to obtain a modified wear-resistant filler.

Embodiment 3

[0043] The preparation method of the organic carbon material is the same as in Example 1. According to the amount added in Example 1, diatomite, organic carbon material, nano-alumina deionized water and silane coupling agent kh-560 are simultaneously removed from the lower side of the side wall of the reaction tank 1. Put it into the reaction tank 1 at the feed port, grind for 2 hours and then stir for 3 hours, filter, wash and dry the obtained material to obtain a modified wear-resistant filler.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com