A composite membrane for high temperature water electrolysis and its preparation method and application

A technology of high-temperature water and composite membranes, applied in applications, electrolytic components, electrolytic processes, etc., can solve the problems of limited improvement of proton conductivity, low conductivity of ionic liquids, and large catalyst poisoning effect, and achieve excellent mechanical strength and good Excellent proton conductivity and oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

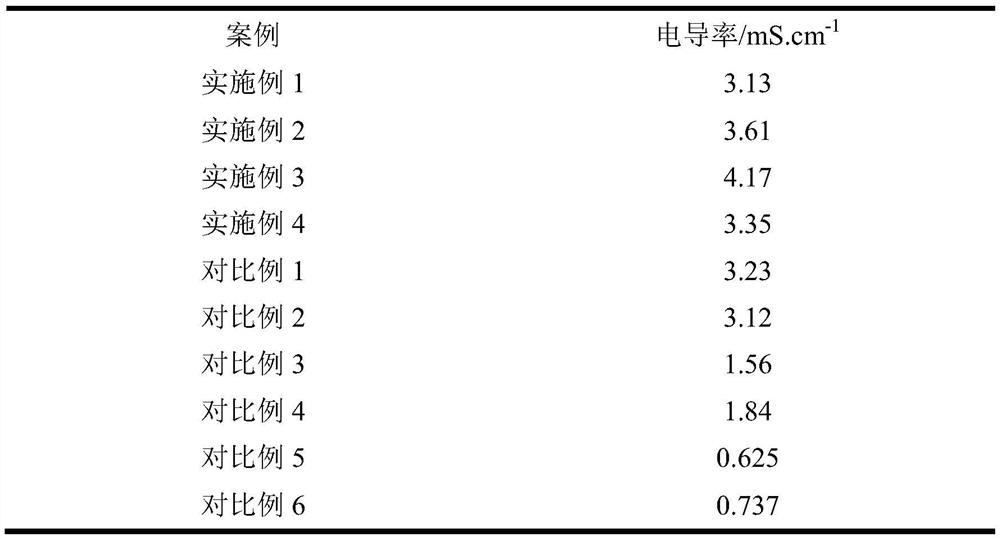

Examples

Embodiment 1

[0024] Step1: Weigh 7.24g of cesium sulfate (0.02mol) and 2.0g of concentrated sulfuric acid (98%, 0.02mol), add slowly to 50ml of deionized water respectively, stir fully with a glass rod, and obtain a transparent and clear solution after fully reacting. After the solution is put into an oven for drying, cesium bisulfate is obtained;

[0025] Step2: Weigh 0.03g mPBI, 0.06g PVDF and dissolve in 27g NMP, stir magnetically for 6 hours to obtain a polymer solution;

[0026] Step3: Weigh 0.21g of cesium bisulfate prepared in Step1 and add it to the polymer solution in Step2, ultrasonically disperse, the ultrasonic power is 200W, and the ultrasonic time is 10h, to obtain a milky white casting solution, which is cast on a flat glass with grooves, After vacuum drying at 80° C. for 30 h, a composite proton exchange membrane for a high-temperature fuel cell was obtained.

Embodiment 2

[0028] Step1: Weigh 7.24g of cesium sulfate (0.02mol) and 4.0g of concentrated sulfuric acid (98%, 0.04mol), add slowly to 70ml of deionized water respectively, stir fully with a glass rod, and obtain a transparent and clear solution after fully reacting. After the solution is put into an oven for drying, cesium dihydrogen sulfate is obtained;

[0029] Step2: Weigh 0.01gmPBI, 0.04g PVDF, 0.01g PTFE and dissolve / disperse in 30gDMAc, stir magnetically for 6h to obtain a polymer solution;

[0030] Step3: Weigh 0.24g of cesium dihydrogen sulfate prepared in Step1 and add it to the polymer solution in Step2, ultrasonically disperse, the ultrasonic power is 300W, and the ultrasonic time is 12h, to obtain a milky white film casting solution, which is cast on a flat glass with grooves , 80 DEG C vacuum drying for 30 hours to obtain a composite proton exchange membrane for high-temperature fuel cells.

Embodiment 3

[0032] Step1: Weigh 7.24g of cesium sulfate (0.02mol) and 4.0g of concentrated sulfuric acid (98%, 0.04mol), add slowly to 70ml of deionized water respectively, stir fully with a glass rod, and obtain a transparent and clear solution after fully reacting. After the solution is put into an oven for drying, cesium dihydrogen sulfate is obtained;

[0033] Step2: Weigh 0.045g mPBI, 0.006g PVDF and dissolve in 30g DMAc, stir magnetically for 6 hours to obtain a polymer solution;

[0034] Step3: Weigh 0.20g of cesium dihydrogen sulfate prepared in Step1 and add it to the polymer solution in Step2, ultrasonically disperse, the ultrasonic power is 300W, and the ultrasonic time is 12h, to obtain a milky white casting solution, which is cast on a flat glass with grooves , 80 DEG C vacuum drying for 30 hours to obtain a composite proton exchange membrane for high-temperature fuel cells.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com