Comprehensive torch system

A torch system and fire cabinet technology, applied in the direction of combustion type, lighting and heating equipment, incinerator, etc., can solve the problems of noise pollution, heat radiation, imperfect supporting facilities, etc., achieve low combustion noise and light pollution, and burnout rate High, the effect of reducing VOCs emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

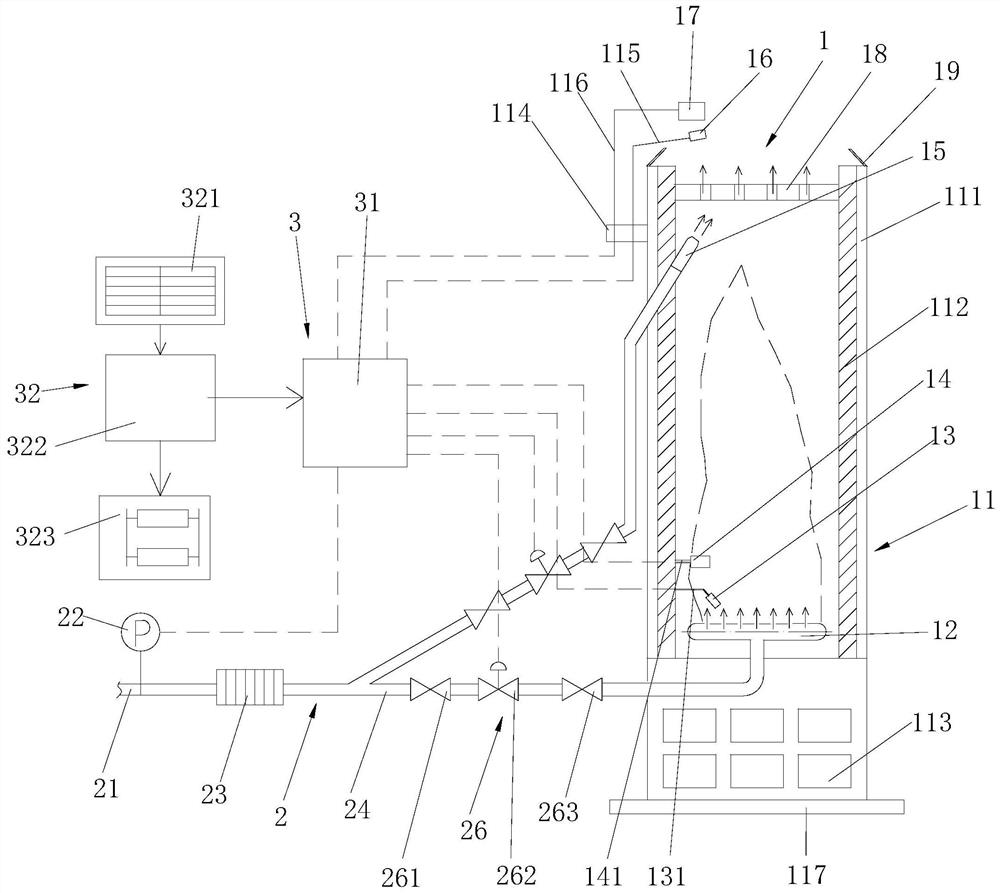

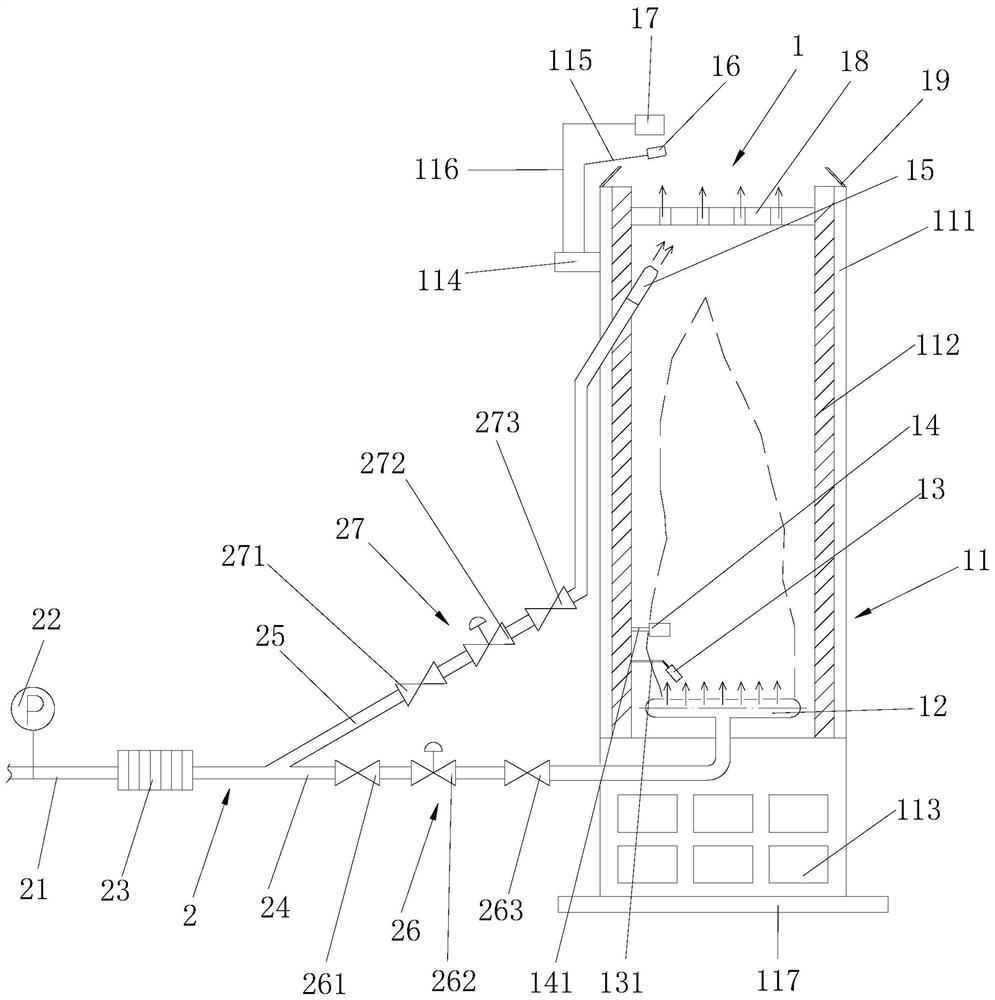

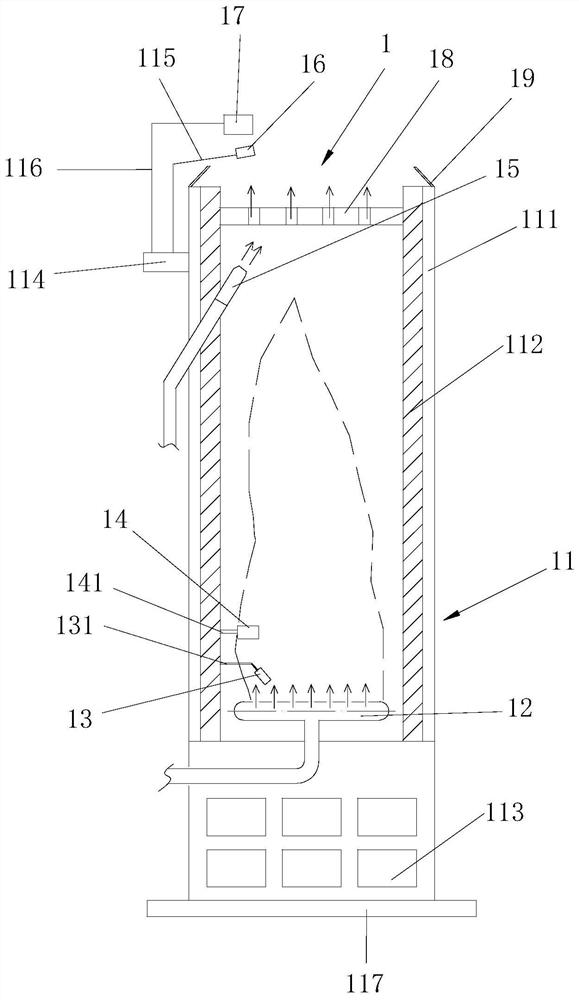

[0032] combine Figure 1 to Figure 6 , an integrated flare system, including a fire cabinet mechanism 1, a conveying mechanism 2 and a control mechanism 3. Firebox mechanism 1 comprises firebox tube 11, is provided with ground burner 12, ground igniter 13 and ground flame monitor 14 in the middle part of firebox tube 11, is provided with high-pressure nozzle 15 in the top of firebox tube 11, and firebox An overhead igniter 16 and an overhead flame detector 17 are arranged above the cylinder 11 .

[0033] The conveying mechanism 2 comprises a first main air pipe 21, a pressure gauge 22 and a flame arrester 23 are arranged on the first main air pipe 21, a low-pressure air pipe 24 and a high-pressure air pipe 25 are connected on the gas outlet of the first main air pipe 21, and a There is a first air pipe control assembly 26, and the air outlet of the low pressure air pipe 24 is connected with the ground burner 12. The high-pressure air pipe 25 is provided with a second air pip...

Embodiment 2

[0047] Taking the combustion treatment of associated gas produced in the oilfield development and production stage as an example to illustrate the integrated flare system, the diameter of the fire tank 11 of an integrated flare system is 0.8m, the height of the cylinder is 6.5m, and the working pressure of the low-pressure gas pipe is 0.6 kPa-15kPa, the processing capacity can reach 600m 3 / d; the working pressure of the high-pressure air pipe is 0-800kpa, and the processing capacity can reach 48000m 3 / d.

[0048] Under normal production conditions, the associated gas produced in the oil field basically enters the ground burner 12 through the low-pressure gas pipe and burns inside the fire cabinet 11. The flame does not emerge from the fire cabinet 11, so that the airtight combustion inside the cylinder is realized, and the elevated flare is in a standby state.

[0049] When the amount of waste gas discharged under emergency working conditions exceeds the combustion load req...

Embodiment 3

[0051] Under normal production conditions, it is difficult to use exhaust gas to be discharged into the exhaust gas pipeline. The pressure is judged in the control cabinet 31 .

[0052] When the pressure is 0.6kpa-15kpa, the ground torch combustion load is met, and the control cabinet 31 transmits the signal to quickly open the first low-pressure solenoid valve 262 and the ground igniter 13, and the exhaust gas passes through the flame arrester 23, the first low-pressure stop valve 261, the second A low-pressure solenoid valve 262 and a second low-pressure shut-off valve 263 enter the ground burner 12 and spray out with pressure, and are ignited by the ground igniter 13, and the ground flame monitor 14 closes the ground igniter 13 after detecting the flame.

[0053] Exhaust gas is sealed and burned inside the fire cabinet tube 11, and the flame does not emerge from the fire cabinet tube 11, so the heat radiation is less. Among them, the ground burner 12 adopts a multi-point i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com