Preparation method of indoor landscape model building material

A landscape model and building material technology, which is applied in the field of preparation of indoor landscape model building materials, can solve the problems of construction waste polluting the environment, difficult to degrade, and non-renewable materials, and achieve the effects of reducing product quality, improving adsorption performance, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

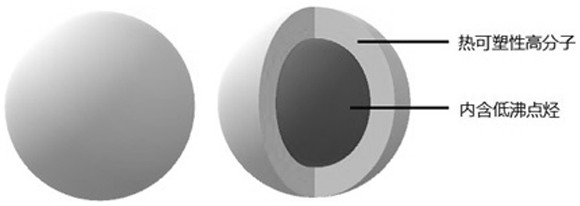

Method used

Image

Examples

Embodiment 1

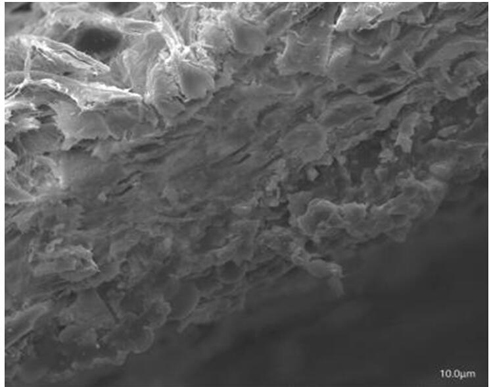

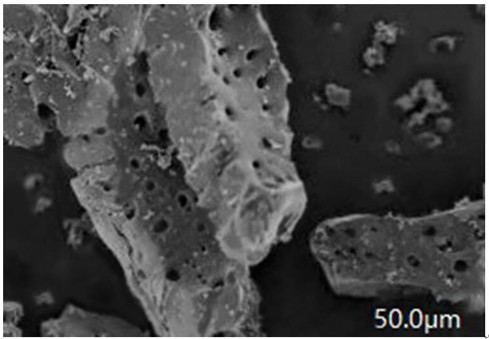

[0055] (1) Preparation of porous carbon frame material raw materials (1.1) Wash the torreya waste material and dry it in an oven at 100°C for 12 hours; after being pulverized by a pulverizer, screen the torreya base material particles with a sieve to obtain the torreya base material with a particle size of 50 mesh Particles, microstructure SEM picture as figure 1 shown;

[0056] (1.2) Activation treatment: Weigh 10g of absolutely dry torreya base material particles and 40% phosphoric acid with a mass concentration of 1g:10mL and mix them in a ratio of 1g:10mL, stir thoroughly, then soak for 24 hours, filter, and use filter paper to initially dry the water to obtain the impregnated Torreya base material;

[0057] (1.3) Steam explosion pretreatment: put the impregnated torreya base material into the steam explosion machine, feed saturated steam, pressurize to 2.2MPa, maintain for 30s, and complete the pressure release within microseconds;

[0058] (1.4) Rinse and filter the p...

Embodiment 2

[0071] (1) Prepare porous carbon frame material raw materials,

[0072] (1.1) After cleaning the Torreya waste material, dry it in an oven at 100°C for 10 hours; after being pulverized by a pulverizer, screen the Torreya base material particles with a sieve to obtain Torreya base material particles with a particle size of 100 mesh;

[0073] (1.2) Activation treatment: Take 50g of absolutely dry Torreya base material and mix it with 40% phosphoric acid in mass concentration according to the ratio of 1g: 10mL, stir thoroughly, then soak for 24h, filter, and use filter paper to preliminarily blot the water to obtain impregnated Torreya base material;

[0074](1.3) Steam explosion pretreatment: put the impregnated torreya base material into the steam explosion machine, feed saturated steam, pressurize to 2.4MPa, maintain for 15s, and complete the pressure release within microseconds;

[0075] (1.4) Rinse and filter the porous carbon frame material obtained by steaming and explosi...

Embodiment 3

[0088] (1) Prepare porous carbon frame material raw materials;

[0089] (1.1) Mechanical crushing and screening: the torreya waste material was washed and dried in an oven at 60°C for 14 hours; after being pulverized by a pulverizer, the torreya base material particles were screened with a sieve to obtain the torreya base material particles with a particle size of 30 mesh;

[0090] (1.2) Activation treatment: Weigh 50g of absolutely dry torreya base material particles and 40% phosphoric acid in a mass concentration and mix them in a ratio of 1g:10mL, stir thoroughly, then soak for 24 hours, filter, and use filter paper to initially dry the water to obtain the impregnated Torreya base particles;

[0091] (1.3) Steam explosion pretreatment: put the impregnated torreya base material into the steam explosion machine, feed saturated steam, pressurize to 2.0MPa, maintain for 60s, and complete the pressure release within microseconds;

[0092] (1.4) Rinse and filter the porous carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com