Arsenic telluride target material and preparation method thereof

A technology of arsenic telluride and diarsenic telluride, which is applied in the field of arsenic telluride target material and its preparation, and can solve problems such as the use or preparation of arsenic telluride target material that has not been reported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

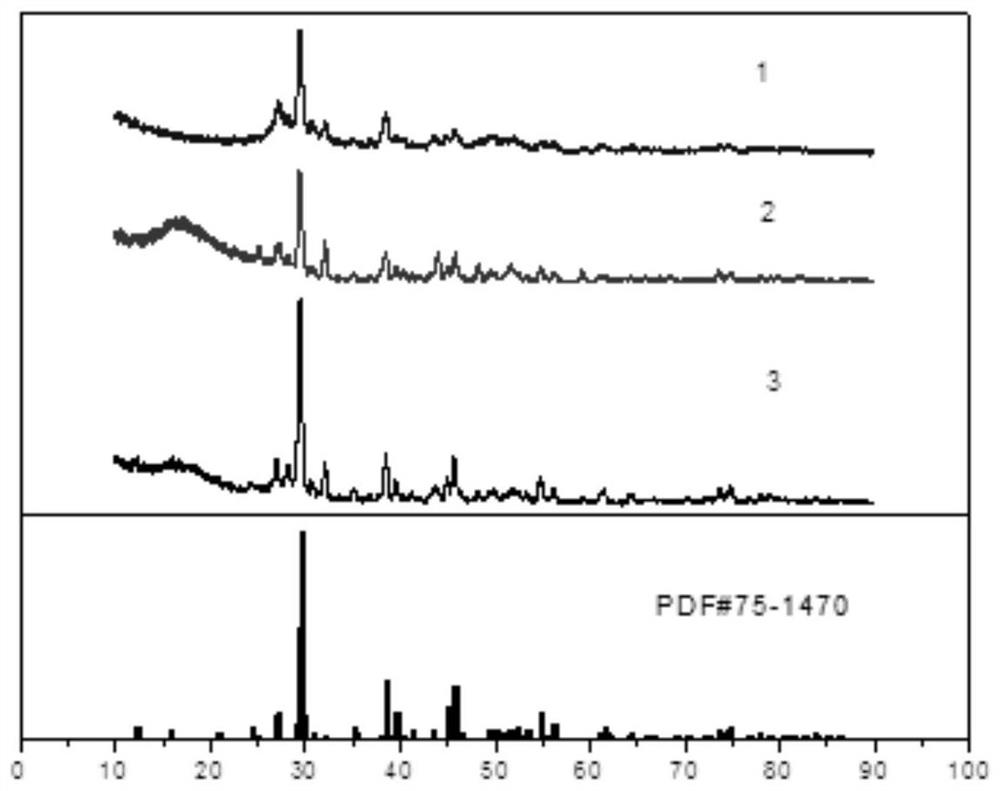

Image

Examples

preparation example Construction

[0019] The method for preparing an arsenic telluride target according to the first aspect of the present invention includes the following steps: step S1, mixing tellurium powder and arsenic powder to obtain a mixed powder; step S2, making the mixed powder in a nitrogen or inert gas atmosphere Two-stage heating and cooling to produce arsenic tritelluride; step S3, crushing and screening the arsenic tritelluride, and sintering the obtained arsenic tritelluride powder by vacuum hot pressing to produce arsenic tritelluride Target material; wherein, in step S2, the two-stage heating includes: in the first stage, heating the mixed powder to 200-300°C at a heating rate of 5-10°C / min, holding the temperature for 20-40min, and In the second stage, heating to 350-450°C at a heating rate of 5-10°C / min, and holding for 20-40min; in step S3, the temperature of the vacuum hot pressing sintering is 300-380°C, and the pressure is 35-50MPa.

[0020] The melting point of arsenic tritelluride is...

Embodiment 1

[0040] Step S1, uniformly mixing 5N tellurium powder with a particle size smaller than 100 mesh and 5N arsenic powder with a particle size smaller than 100 mesh according to a mass ratio of 1.5:1 to obtain a mixed powder;

[0041] Step S2, put the mixed powder into a tube furnace, continuously feed nitrogen or inert gas, and heat to 200°C at a heating rate of 5°C / min, keep it for 20 minutes, and then heat to 350°C at a heating rate of 5°C / min , keep warm for 20min, then cool with the furnace;

[0042] In step S3, the product of arsenic tritelluride synthesized in step S2 is crushed into powder by ball milling, passed through a 100-mesh sieve, and then the sieved arsenic tritelluride powder is put into a graphite mold, and sintered by vacuum hot pressing to obtain Arsenic telluride target;

[0043] Among them, the temperature of the vacuum hot pressing sintering is 300°C, the pressure is 35MPa, the pressure is started after holding the heat for 20-30min, the holding time is 30...

Embodiment 2

[0046] Step S1, uniformly mixing 5N tellurium powder with a particle size smaller than 100 mesh and 5N arsenic powder with a particle size smaller than 100 mesh according to a mass ratio of 1.7:1 to obtain a mixed powder;

[0047] Step S2, put the mixed powder into a tube furnace, continuously feed nitrogen or inert gas, and heat to 250°C at a heating rate of 7.5°C / min, keep it for 30min, and then heat to 400°C at a heating rate of 7.5°C / min , keep warm for 30min, then cool with the furnace;

[0048] In step S3, the product of arsenic tritelluride synthesized in step S2 is crushed into powder by ball milling, passed through a 100-mesh sieve, and then the sieved arsenic tritelluride powder is put into a graphite mold, and sintered by vacuum hot pressing to obtain Arsenic telluride target;

[0049] Among them, the temperature of vacuum hot pressing sintering is 340°C, the pressure is 42.5MPa, the pressure is started after holding the heat for 20-30min, the pressure holding time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com