Method for accelerating liquor and spirits to age

A liquor and aging technology, applied in the field of liquor, can solve the problems of not simulating the natural aging process of liquor, unstable and long-lasting ripening effect, depolymerization and dispersion, etc., to reduce the occupied area of liquor storage, reduce the share of funds, Harmonious and full-bodied effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: a kind of method of promoting aging of liquor

[0027] The method comprises the steps of:

[0028] (1) smash the pottery altar into fragments with a hammer, and then use a pulverizer to crush the pottery into pottery powder, and the pottery powder passes through a 20-mesh sieve;

[0029] (2) During the aging process of liquor, the pottery powder (90 g) prepared in step (1) was added to liquor (200 mL), and placed at 25° C. for 10 days. Uncap and stir once a day to let in fresh air.

Embodiment 2

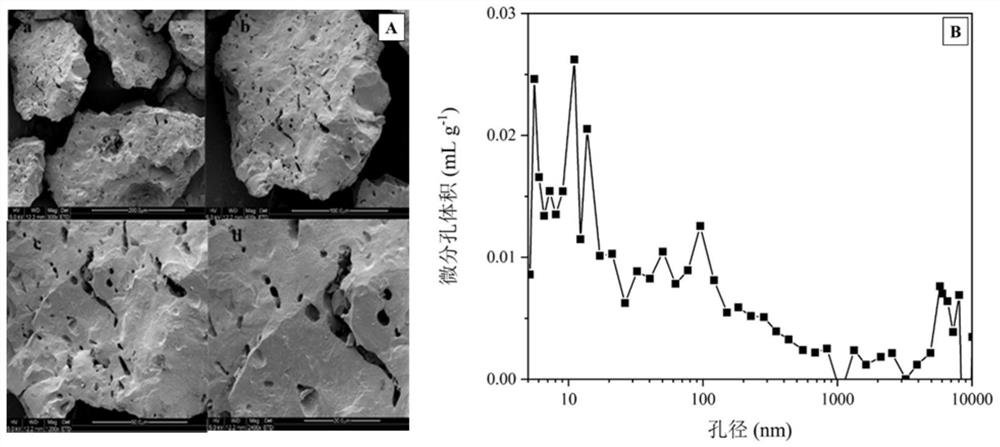

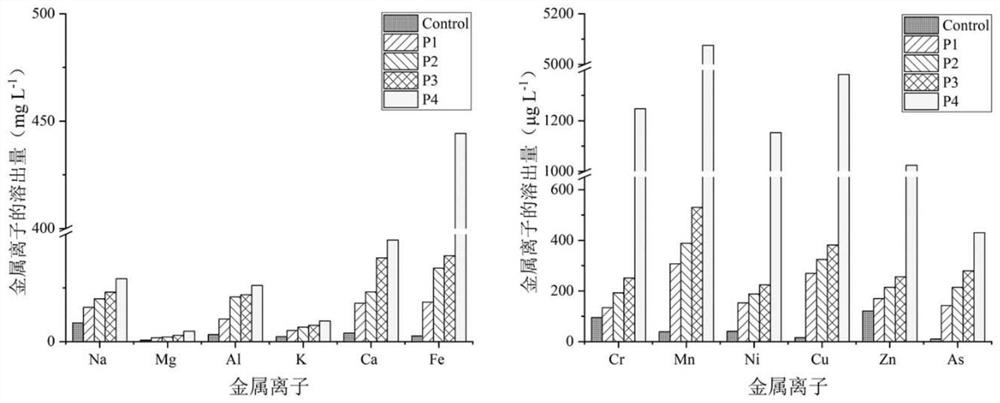

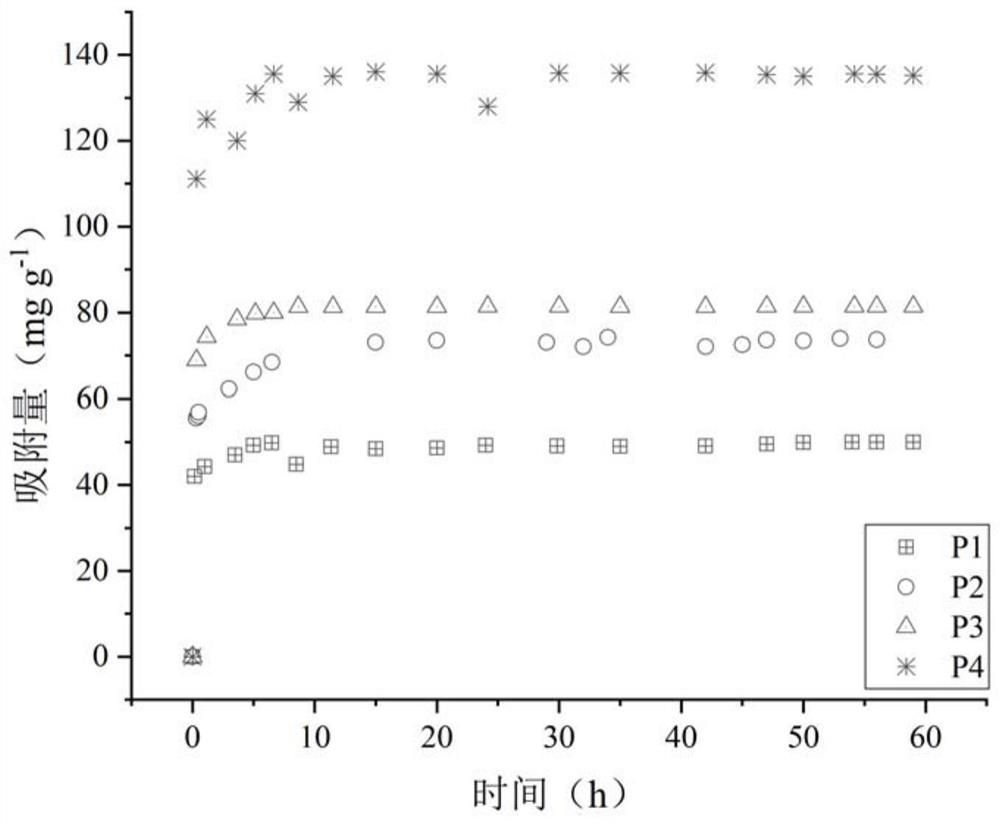

[0030] Example 2: Effect of pottery powder particle size on aging effect of liquor

[0031] (1) Use a hammer to smash the pottery altar into pieces, and then use a crusher to crush the pottery pieces into pottery powder. The pottery powder is passed through sieves of 10 mesh, 20 mesh, 40 mesh, 60 mesh, and 80 mesh, and is divided into four different types. Particle size: P1 (10-20 mesh), P2 (20-40 mesh), P3 (40-60 mesh), P4 (60-80 mesh);

[0032] (2) During the aging process of liquor, four pottery powders (90 g) with different particle sizes prepared in step (1) were added to liquor (200 mL) respectively, placed at 25°C for 10 days, and the bottle cap was opened once a day and Stir to let in fresh air.

[0033] Table 1 Experimental design of different ceramic powder particle sizes

[0034]

[0035] Note: P1: 10-20 mesh pottery powder; P2: 20-40 mesh pottery powder; P3: 40-60 mesh pottery powder; P4: 60-80 mesh pottery powder.

Embodiment 3

[0036] Embodiment 3: The effect of the amount of pottery powder added on the aging effect of liquor

[0037] Due to the large particle size of P1 ceramic powder, the aging effect is not obvious; the particle size of P4 ceramic powder is too small, and the adsorption and dissolution effects are strong; therefore, P2 and P3 ceramic powders were selected for subsequent experiments. Weigh 11.25g, 22.50g, 45.00g, 90.00g of P2, P3 respectively in 200mL liquor (that is, the addition amount is 5.63%, 11.25%, 22.50%, 45.00% w / v, g / mL), another group A comparative test was carried out without adding ceramic powder, and the storage conditions were the same as in Table 1. After the storage, a sensory analysis was carried out. The results showed that when the ceramic powder particle size was 20-40 mesh (P2), and the addition amount was 11.25% w / v, Storage for 10 days does not affect the style of the wine body, removes new wine smell and other miscellaneous odors in a short period of time, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com