Vacuum co-reduction synergistic utilization method for sulfuric-acid residues and fly ash

A technology of fly ash and sulfuric acid slag, which is applied to the improvement of process efficiency, alumina/hydroxide, etc., to achieve the effects of less energy consumption, environmental protection and simplicity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

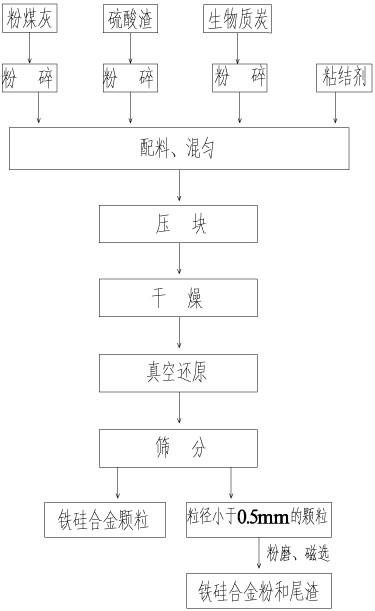

[0025] A method for synergistic utilization of sulfuric acid slag and fly ash vacuum co-reduction in this embodiment, see figure 1 , including the following steps:

[0026] (1) Briquetting: Weigh 20 kg of fly ash and 15 kg of sulfuric acid slag as raw materials, and 52 kg of biochar as a reducing agent. The fly ash and sulfuric acid slag need to be pulverized and pretreated so that the particle size is less than 200 meshes. More than 80%, and then the biomass charcoal is crushed so that the particle size is less than 100 mesh, accounting for more than 80%. Then add 13.9 kg of binder and mix well, put it in a press with a pressure of 20MPa and press it into a cylindrical compact with a diameter of 20 mm and a height of 18 mm; the binder is a polymer with a mass fraction of 15 wt%. Vinyl alcohol; the mass percentages of main components in sulfuric acid slag are: TFe 65.76%, SiO 2 1.82%, Al 2 o 3 0.38%, CaO 0.46%, SO 3 1.64%, Na 2 O 0.61 %; the mass percentage of main com...

Embodiment 2

[0031] A method for synergistic utilization of sulfuric acid slag and fly ash vacuum co-reduction in this embodiment, see figure 1 , including the following steps:

[0032] (1) Briquetting: Weigh 20 kg of fly ash and 11 kg of sulfuric acid slag as raw materials, and 40 kg of biochar as a reducing agent. The fly ash and sulfuric acid slag need to be pulverized and pretreated so that the particle size is less than 200 meshes. More than 80%, and then the biomass charcoal is crushed so that the particle size is less than 100 mesh, accounting for more than 80%. Then add 9.2 kg of binder and mix well, put it in a press with a pressure of 18 MPa and press it into a cylindrical compact with a diameter of 20 mm and a height of 22 mm; the binder is a polymer with a mass fraction of 18 wt%. Vinyl alcohol; the mass percentages of main components in sulfuric acid slag are: TFe 60.72%, SiO 2 3.87%, Al 2 o 3 2.32%, CaO 2.14%, SO 3 1.83%, Na 2 O 0.76 %; the mass percentage of main comp...

Embodiment 3

[0037] In this embodiment, a method for synergistic utilization of sulfuric acid slag and fly ash vacuum co-reduction, see figure 1 , including the following steps:

[0038] (1) Briquetting: Weigh 20 kg of fly ash and 13 kg of sulfuric acid slag as raw materials, and 55 kg of biochar as a reducing agent. The fly ash and sulfuric acid slag need to be pulverized and pretreated to make the particle size less than 200 meshes. More than 80%, and then the biomass charcoal is crushed so that the particle size is less than 100 mesh, accounting for more than 80%. Then add 10.6 kg of binder and mix well, put it in a press with a pressure of 15MPa and press it into a cylindrical compact with a diameter of 20 mm and a height of 16 mm; the binder is a polymer with a mass fraction of 14 wt%. Vinyl alcohol; the mass percentages of main components in sulfuric acid slag are: TFe 63.23%, SiO 2 3.16%, Al 2 o 3 1.42%, CaO 1.07%, SO 3 1.72%, Na 2 O 0.65 %; the mass percentage of main comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com