A metallurgical sintering treatment method for waste scr flue gas denitrification catalyst

A technology of denitrification catalyst and sintering treatment, which is applied in the field of environmental protection and iron and steel metallurgical engineering, and can solve the problems of high treatment cost, high cost of recycling heavy metals, unsuitable for mass production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

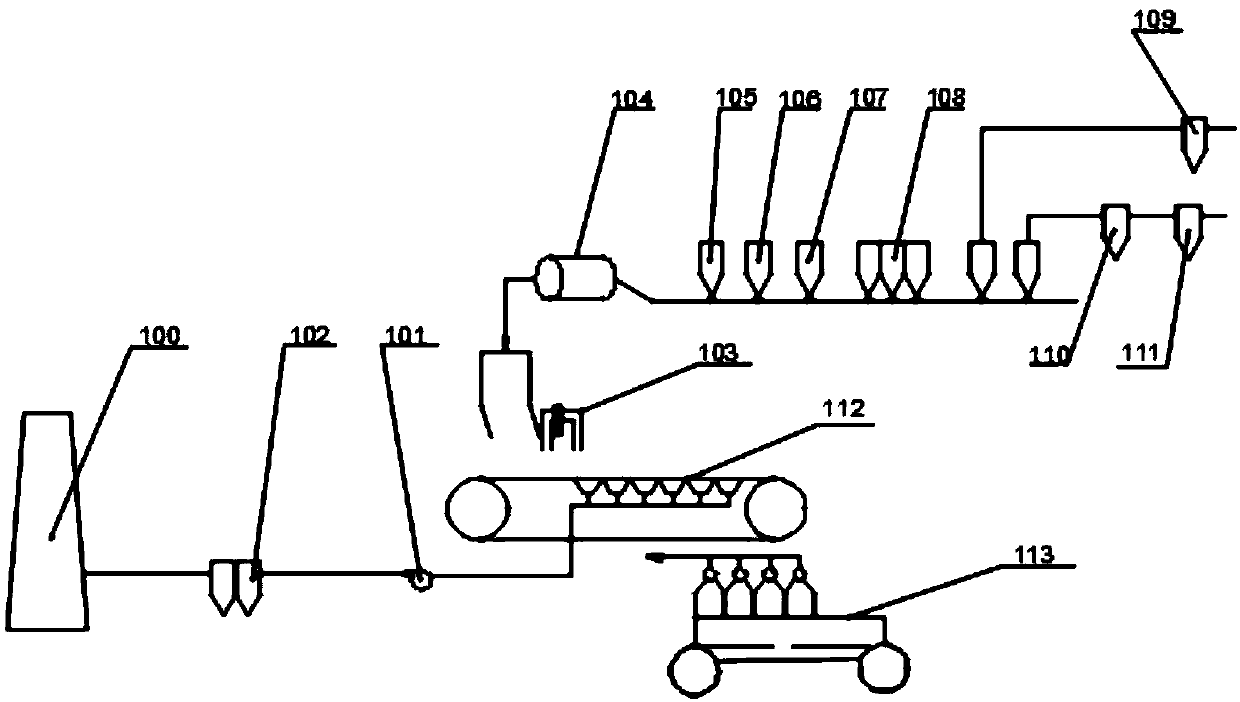

[0029] Such as figure 1 As shown, the process system for metallurgical sintering treatment of waste SCR flue gas denitrification catalyst includes 100 chimney, 101 induced draft fan, 102 bag filter, 103 sintering machine igniter, 104 pelletizing equipment, 105 fuel, 106 return ore, 107 flux, 108 Iron ore powder, 109 grinding equipment, 111 polishing machine, 110 cutting machine, 112 sintering machine trolley and 113 cooling machine.

[0030] In this embodiment, the metallurgical sintering process of the waste SCR flue gas denitrification catalyst is as follows:

[0031] (1) Catalyst crushing: The waste SCR flue gas denitrification catalyst unit is separated from the module, and each unit is crushed and ground.

[0032] If the waste SCR flue gas denitrification catalyst is a flat-plate denitrification catalyst, the veneer is first ground by a grinder 111 to obtain a catalyst powder of 100 to 200 mesh, and the ground stainless steel mesh is crushed by a cutting machine 110 to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com