A kind of recycling method of waste liquid metal battery

A liquid metal battery and recycling method technology, applied in battery recycling, waste collector recycling, recycling technology and other directions, can solve the problems of heavy metals, high material cost, economic loss, etc., and achieve low equipment requirements, simple procedures, The effect of low recovery cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A recovery method for lithium bismuth liquid metal battery, comprising the following steps:

[0038] Step 1. Charge the waste lithium-bismuth liquid metal battery so that the voltage of the single battery reaches 0.5V, and then cool it down to room temperature;

[0039] Step 2. Disassemble the cooled lithium-bismuth liquid metal battery, and cut to obtain air pipes, copper current collectors, ceramic sealing rings and battery cells.

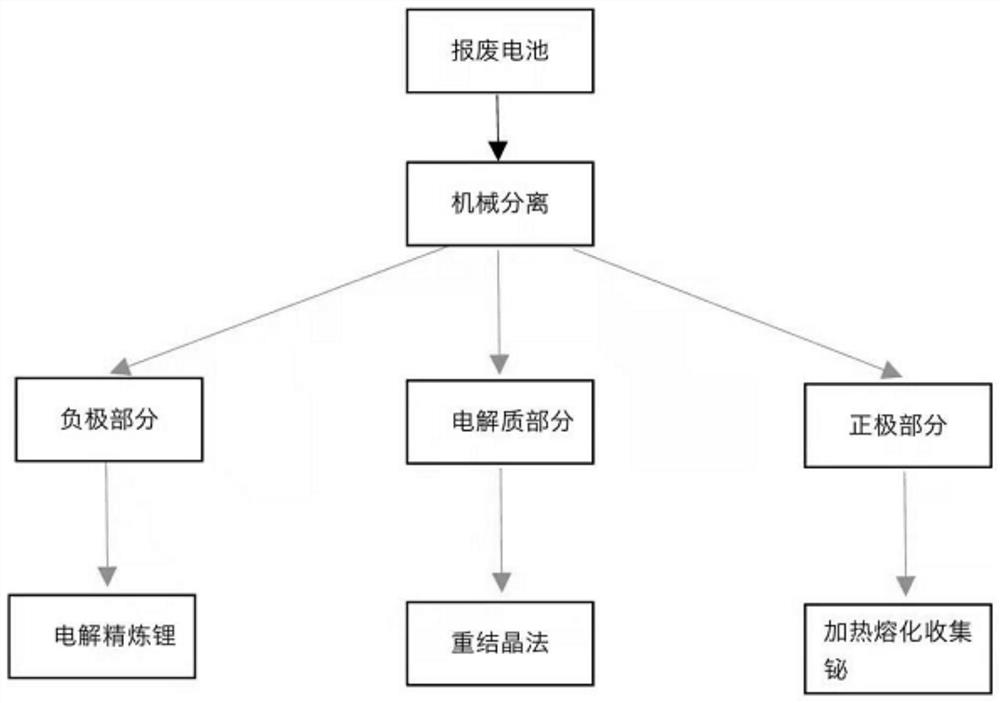

[0040] Step 3. Cut the battery cells, and use mechanical crushing method to separate the three parts of negative electrode, electrolyte and positive electrode according to the color.

[0041] Step 4, immerse the negative electrode foam nickel in dilute hydrochloric acid, purify the solution, and dry to obtain lithium chloride powder, then add a certain amount of potassium chloride for electrolytic refining to obtain pure lithium;

[0042]The electrolyte part can be separated and placed in deionized water to raise the temperature to 100°C....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com