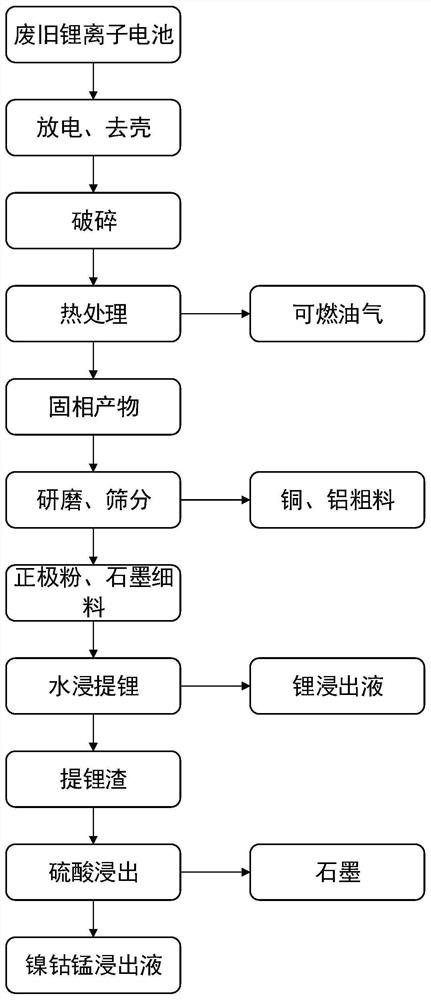

A method for recovering all components of waste lithium-ion batteries

A lithium-ion battery, full-component technology, which is applied in the field of full-component recovery of waste lithium-ion batteries, can solve the problems of high reagent cost and easy generation of harmful gases, achieves simple process, large industrial application prospects, and reduces metal extraction costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (1) Discharge 1 kg of waste nickel-cobalt lithium manganate battery, remove the shell and crush it, and the particle size of the crushed material is less than 10 mm.

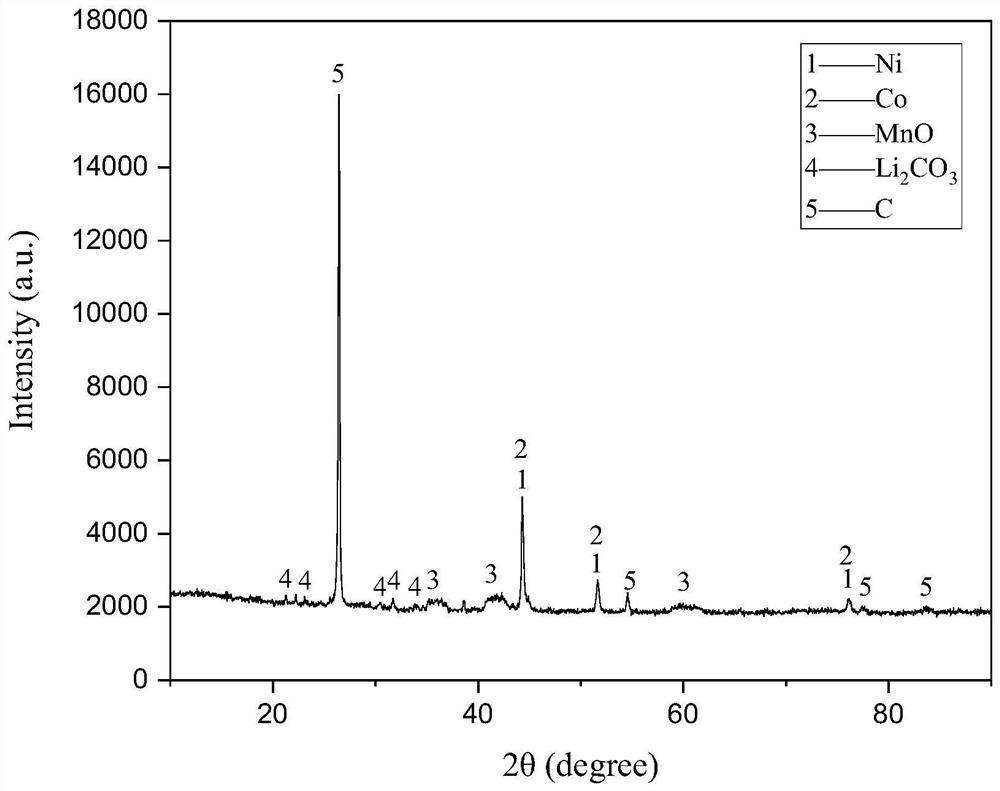

[0055] (2) All the materials (positive and negative plates, diaphragm, electrolyte) obtained by crushing the step (1) are placed in N 2 The heat treatment is carried out under the atmosphere. The heat treatment device is a horizontal furnace, N 2 The flow rate is 45mL / min, the heat treatment temperature is 550°C, and the heat treatment time is 1h. There is no external reagent during the heat treatment process. The self-reduction reaction occurs during the heat treatment process, the positive electrode powder is reduced, and the organic matter (diaphragm, binder, electrolyte) turns into a flammable Oil and gas (wherein, the gas chromatography-mass spectrum of oil see Figure 4 ), the copper-aluminum foil current collector did not react. After heat treatment, the material is in N 2 Naturally cooled to r...

Embodiment 2

[0060] (1) Discharge 1 kg of waste lithium manganate battery, remove the shell and crush it, and the particle size of the crushed material is less than 10mm;

[0061] (2) All the materials (positive and negative plates, diaphragm, electrolyte) obtained by crushing the step (1) are placed in N 2 The heat treatment is carried out under the atmosphere. The heat treatment device is a horizontal furnace, N 2 The flow rate is 100mL / min, the heat treatment temperature is 600°C, and the heat treatment time is 2h. There is no external reagent during the heat treatment process. The self-reduction reaction occurs during the heat treatment process, the positive electrode powder is reduced, and the organic matter (diaphragm, binder, electrolyte) turns into a flammable Oil and gas, copper and aluminum foil current collectors did not react. After heat treatment, the material is in N 2 Naturally cooled to room temperature under atmosphere.

[0062] (3) Grinding and sieving the heat-treate...

Embodiment 3

[0066] (1) Discharge 1 kg of waste lithium cobalt oxide battery, remove the shell and crush it, and the particle size of the crushed material is less than 5mm.

[0067] (2) All the materials (positive and negative plates, diaphragm, electrolyte) obtained by crushing the step (1) are placed in N 2 The heat treatment is carried out under the atmosphere. The heat treatment device is a horizontal furnace, N 2 The flow rate is 80mL / min, the heat treatment temperature is 650°C, and the heat treatment time is 0.5h. There is no external reagent in the heat treatment process. The self-reduction reaction occurs during the heat treatment process, the positive electrode powder is reduced, and the organic matter (diaphragm, binder, electrolyte) is transformed into Combustible fuel gas, copper and aluminum foil current collectors did not react. After heat treatment, the material is in N 2 Naturally cooled to room temperature under atmosphere.

[0068] (3) Grinding and sieving the heat-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com