A kind of recycling method of vinyltrichlorosilane waste catalyst

A technology of vinyl trichlorosilane and waste catalysts, which is applied in the field of collaborative recovery of waste catalysts produced in the production process of vinyl trichlorosilane, can solve the problems of platinum ineffective recovery, complex components, and low conversion rate, and achieve the elimination of silane The effect of low conversion rate of organic matter, low material consumption and energy consumption, and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

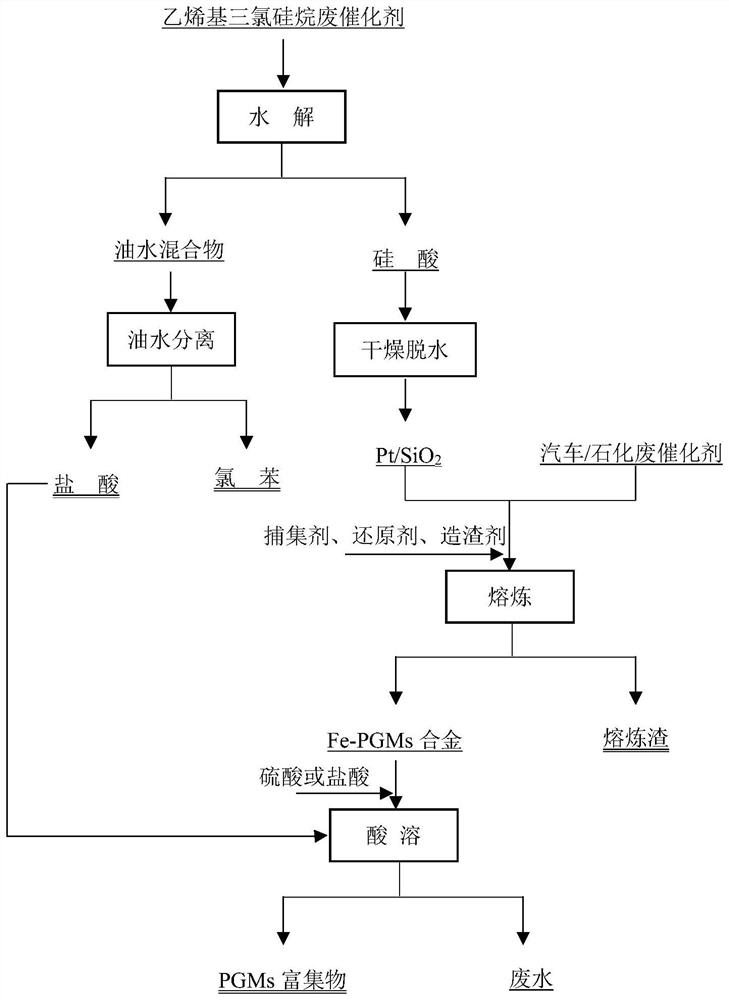

Method used

Image

Examples

Embodiment 1

[0032] Slowly add 500 parts of water to 100 parts of vinyltrichlorosilane spent catalyst, stir, and hydrolyze for 20 minutes. After hydrolysis is complete, press filter to obtain oil-water mixture and silicic acid. The density difference is used to separate hydrochloric acid and chlorobenzene in the oil-water mixture, hydrochloric acid is used for wet leaching of platinum group metals, and chlorobenzene is used for industrial raw materials. After the silicic acid is dehydrated and dried at 150°C, it is mixed with 100 parts of waste automobile exhaust catalyst, 100 parts of calcium oxide, 20 parts of iron powder, and 10 parts of coke powder, and melted at 1300°C. After the reaction is complete, the slag and gold are separated. An iron-based alloy phase rich in platinum group metals and a smelting slag are obtained.

Embodiment 2

[0034] Slowly add 600 parts of water to 100 parts of vinyltrichlorosilane spent catalyst, stir, and hydrolyze for 85 minutes. After hydrolysis is complete, press filter to obtain oil-water mixture and silicic acid. The density difference is used to separate hydrochloric acid and chlorobenzene in the oil-water mixture, hydrochloric acid is used for wet leaching of platinum group metals, and chlorobenzene is used for industrial raw materials. After the silicic acid is dehydrated and dried at 180°C, it is mixed with 150 parts of alumina carrier waste petrochemical catalyst, 100 parts of calcium oxide, 100 parts of sodium carbonate, 20 parts of calcium fluoride, 30 parts of iron oxide, and 50 parts of coke powder. Melting at ℃, after the reaction is complete, the slag and gold are separated to obtain an iron-based alloy phase rich in platinum group metals and smelting slag.

Embodiment 3

[0036] Slowly add 700 parts of water to 100 parts of vinyltrichlorosilane spent catalyst, stir, and hydrolyze for 150 minutes. After hydrolysis is complete, press filter to obtain oil-water mixture and silicic acid. The density difference is used to separate hydrochloric acid and chlorobenzene in the oil-water mixture, hydrochloric acid is used for wet leaching of platinum group metals, and chlorobenzene is used for industrial raw materials. After the silicic acid is dehydrated and dried at 200°C, it is mixed with 300 parts of alumina carrier waste petrochemical catalyst, 200 parts of calcium oxide, 30 parts of calcium fluoride, 40 parts of iron concentrate, and 40 parts of carbon powder, and smelted at 1400°C. After the reaction is complete, the slag and gold are separated to obtain an iron-based alloy phase rich in platinum group metals and smelting slag.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com