Rolled (FeCoNiCrRn/Al)-2024Al composite board and preparation method therefor

A composite plate and composite material technology, applied in metal rolling and other directions, can solve problems such as low ductility and limited application range, and achieve the effect of saving costs and improving the mechanical properties of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

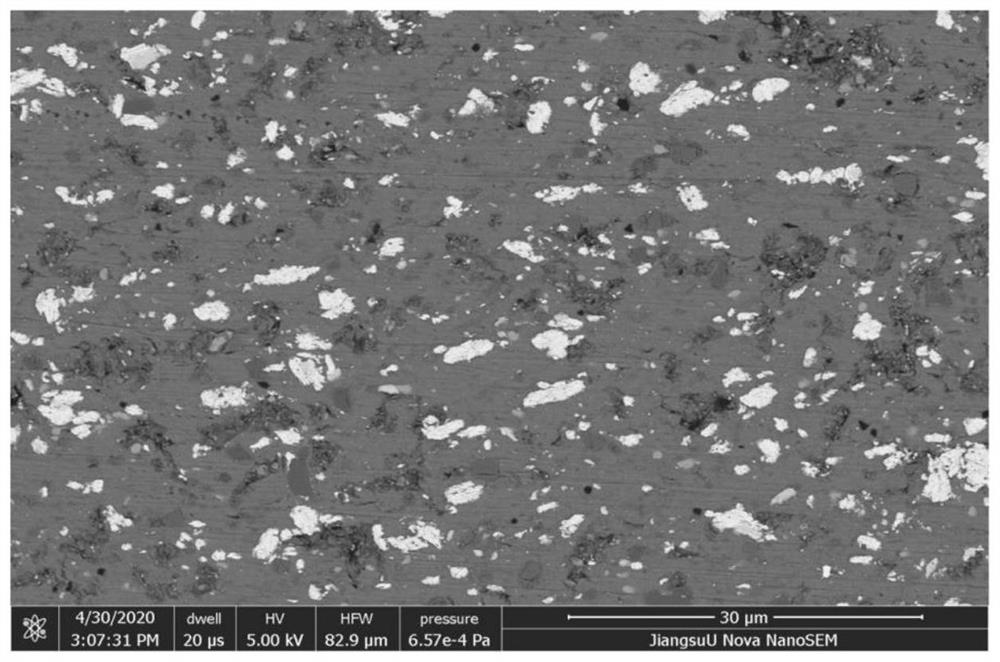

[0029] (1) Preparation of medium entropy alloy powder: the reinforcing base is FeCoNiCrC 0.2 For medium-entropy alloys, according to the ratio of atomic number 1:1:1:1:0.2, calculate and weigh the corresponding mass of powder, put the mixed powder in the ball mill jar, vacuumize and pass in argon, and then high-energy Ball milling for mechanical alloying. The parameters of ball milling are as follows: the mass ratio of ball to material is 12:1, dry milling for 30 hours at a speed of 150 r / min, and then adding absolute ethanol as a process control agent, wet milling for 12 hours at a speed of 300 r / min. Dry for 60h to obtain high entropy alloy powder.

[0030] (2) Preparation of composite powder: the high-entropy alloy powder particles and pure aluminum powder are mixed, and the addition amount of the high-entropy alloy powder particles of the reinforcing phase is 20% by mass fraction. The composite powder is obtained by ball milling with a ball mill, and the ball milling is ...

Embodiment 2

[0036] (1) Preparation of medium entropy alloy powder: the reinforcing base is FeCoNiCrC 0.5 For medium-entropy alloys, according to the ratio of atomic number 1:1:1:1:0.5, calculate and weigh the corresponding mass of powder, put the mixed powder in the ball mill jar, vacuumize and pass in argon, and then high-energy Ball milling for mechanical alloying. The parameters of ball milling are as follows: the mass ratio of ball to material is 12:1, dry milling for 30 hours at a speed of 150 r / min, and then adding absolute ethanol as a process control agent, wet milling for 12 hours at a speed of 300 r / min. Dry for 60h to obtain high entropy alloy powder.

[0037] (2) Preparation of composite powder: the high-entropy alloy powder particles and pure aluminum powder are mixed, and the addition amount of the high-entropy alloy powder particles of the reinforcing phase is 20% by mass fraction. The composite powder is obtained by ball milling with a ball mill, and the ball milling is ...

Embodiment 3

[0043] (1) Preparation of medium entropy alloy powder: the reinforcing base is FeCoNiCrB 0.5 For medium-entropy alloys, according to the ratio of atomic number 1:1:1:1:0.5, calculate and weigh the corresponding mass of powder, put the mixed powder in the ball mill jar, vacuumize and pass in argon, and then high-energy Ball milling for mechanical alloying. The parameters of ball milling are as follows: the mass ratio of ball to material is 12:1, dry milling for 30 hours at a speed of 150 r / min, and then adding absolute ethanol as a process control agent, wet milling for 12 hours at a speed of 300 r / min. Dry for 60h to obtain high entropy alloy powder.

[0044] (2) Preparation of composite powder: the high-entropy alloy powder particles and pure aluminum powder are mixed, and the addition amount of the high-entropy alloy powder particles of the reinforcing phase is 20% by mass fraction. The composite powder is obtained by ball milling with a ball mill, and the ball milling is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com