Preparation method of thermal reduction graphene oxide modified graphite cathode

A graphite cathode and graphene technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of poor hydrophobicity, small specific surface area, small pore size of reduced graphene oxide, etc., and achieve high conductivity and stable electrode Good performance and the effect of promoting electron transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

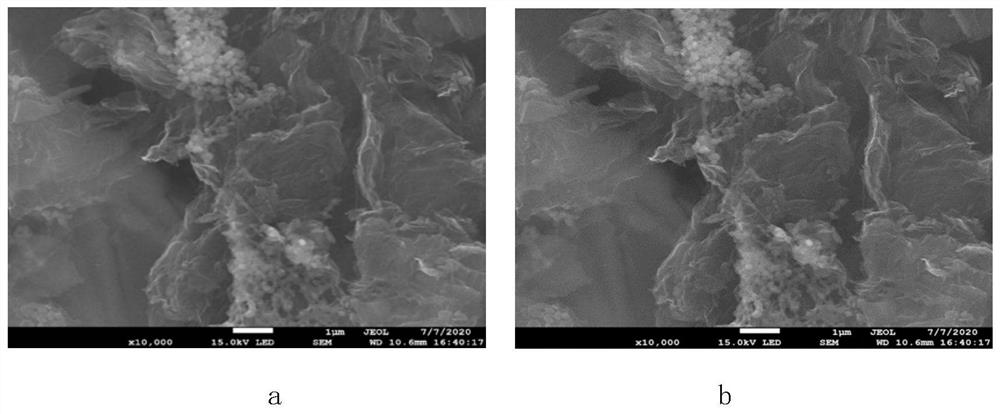

[0019] Embodiment 1: the preparation of a graphite cathode modified by thermally reducing graphene oxide, the method is as follows:

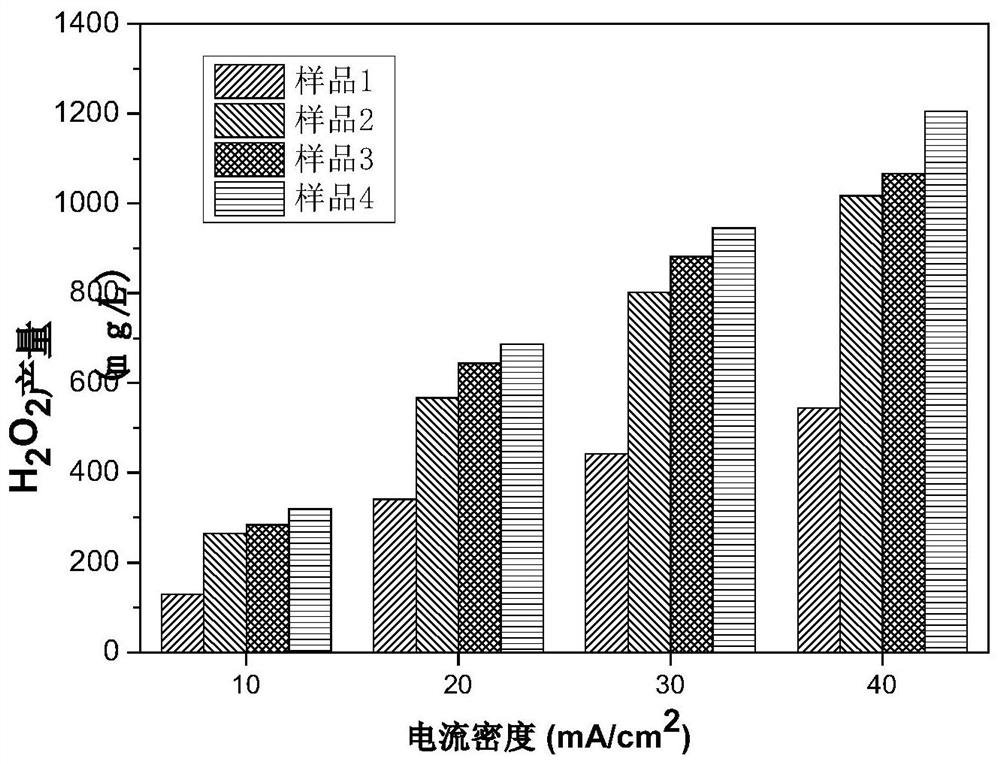

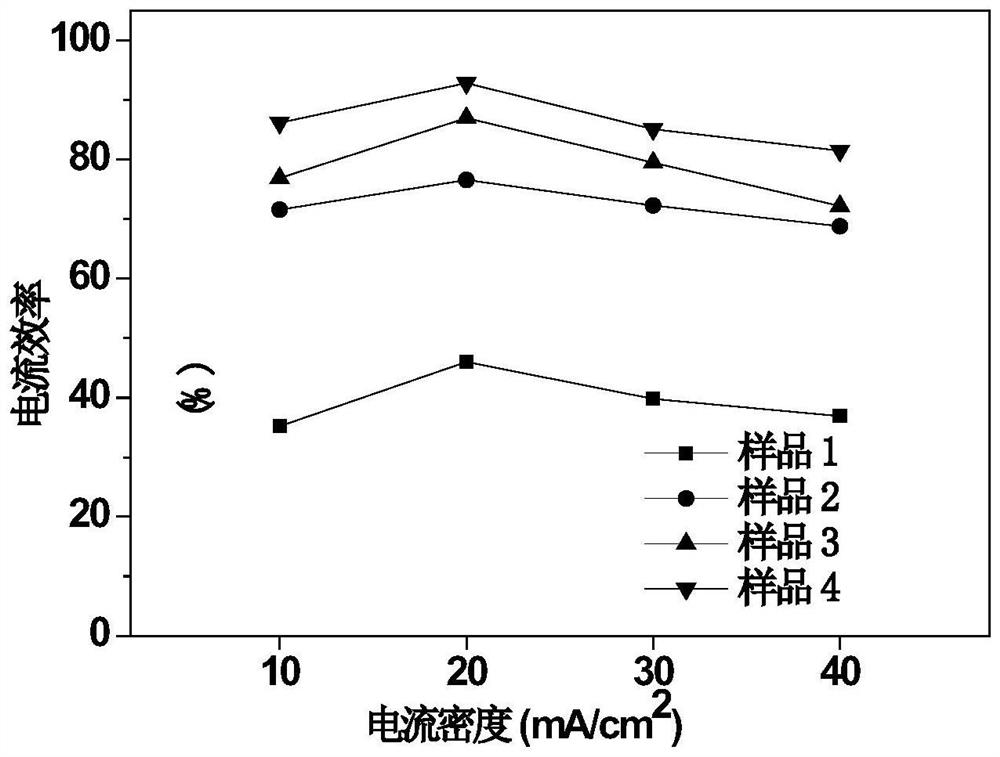

[0020] Mix 1.1g of graphite powder with 40mL of absolute ethanol, and stir ultrasonically for 10min to disperse the graphite evenly in absolute ethanol. Under ultrasonic stirring, slowly add 0.46mL of polytetrafluoroethylene emulsion, and then ultrasonically stir for 10min; then , heated in a water bath at 60°C until it becomes a colloidal paste, and pressed into a 0.5mm sheet using a roller press. During the rolling process, anhydrous ethanol must be sprayed to ensure its adhesion. The catalytic layer obtained in this comparative example is designated as sample 1.

Embodiment 2

[0021] Example 2: Preparation of a thermally reduced graphene oxide-modified graphite cathode, the method is as follows: Take 1.0 g of graphite powder, 0.1 g of reduced graphene oxide (reduced at 700° C.) and mix them with 40 mL of absolute ethanol, and ultrasonically stir 10min, the graphite and reduced graphene oxide powder were uniformly dispersed in absolute ethanol, under the condition of ultrasonic stirring, slowly added 0.46mL polytetrafluoroethylene emulsion, and then ultrasonically stirred for 10min; then, heated in a water bath at 60°C for 20min to make It becomes a colloidal paste, which is pressed into a 0.5mm sheet using a roller press, and absolute ethanol must be sprayed during the rolling process to ensure its adhesion. The catalytic layer obtained in this comparative example is designated as sample 2.

Embodiment 3

[0022] Example 3: Preparation of a thermally reduced graphene oxide-modified graphite cathode, the steps of which are the same as in Example 2, the only difference being that the reduced graphene oxide in the catalytic layer is reduced at 900°C, and this example is recorded as a sample 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com