A timing drive system, engine and motor vehicle

A transmission system and engine technology, applied in the direction of engine components, machines/engines, transmission devices, etc., can solve the problems of complex structure of electronic control transmission system, large size of gear timing transmission, and no promotion and use, etc., to achieve light weight and structure Compact, full-featured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

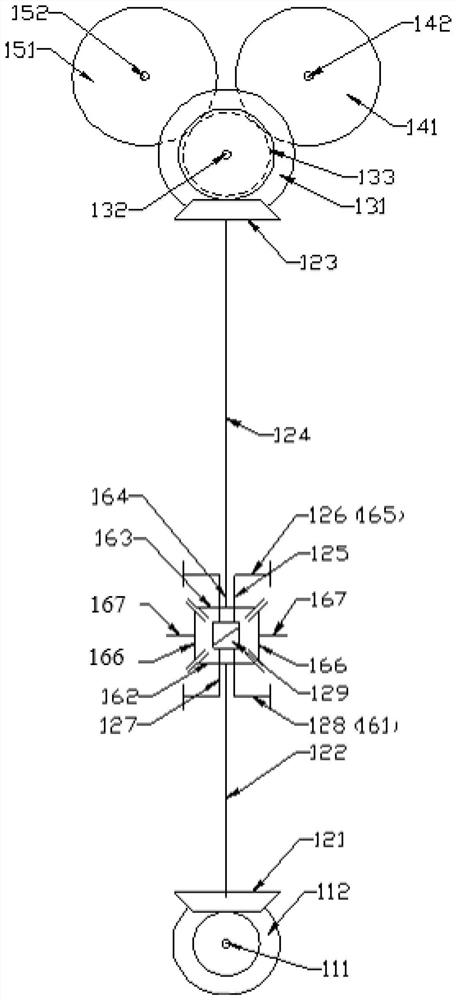

[0063] This embodiment is a timing drive system, such as figure 1 and figure 2 As shown, the timing transmission system includes a bevel gear set 100 , through which the engine crankshaft can be simultaneously drive-connected with the intake camshaft 142 and the exhaust camshaft 152 . It should be noted that the bevel gear set 100 has a variety of structural forms or components. The difference between the bevel gear set 100 and the existing timing transmission system is that the bevel gear set 100 has the ability of long-distance transmission and can have the same lifespan as the engine. That is, by adjusting the length of the transmission shaft in the bevel gear set 100, the long-distance free power transmission between the engine crankshaft and the intake camshaft 142 and the exhaust camshaft 152 can be realized, avoiding the problem of large size of the traditional gear timing transmission system, The structure is compact and the weight is light; the problems of easy wear...

Embodiment 2

[0073] This embodiment is an engine, such as figure 1 and figure 2 As shown, this embodiment includes the timing transmission system described in the above embodiments, and the same parts thereof will not be repeated here.

[0074] Specifically, the engine further includes: a casing and an engine main body installed inside the casing. The engine main body is the power part of the engine, and has engine cylinders, a crankshaft, an intake camshaft 142 and an exhaust camshaft 152 .

[0075] Further, wherein, the crankshaft is connected to the engine output shaft 111, the intake camshaft 142 is equipped with an intake camshaft column gear 141, and the exhaust camshaft 152 is equipped with an exhaust camshaft column gear 151 . Furthermore, the problem of large size of the traditional gear timing transmission system is avoided, and the structure is compact and light in weight; the problems of easy wear of the belt and high cost of use in the belt timing transmission are avoided....

Embodiment 3

[0077] This embodiment is an engine, such as image 3 and Figure 4 As shown, this embodiment adds forward and reverse functions on the basis of the engine proposed in Embodiment 2, and the same parts will not be repeated here.

[0078] Specifically, between the crankshaft and the intake camshaft 142 and the exhaust camshaft 152, a forward and reverse bevel gear set and a forward and reverse switch are arranged; the crankshaft is provided with a crankshaft centering adjustment device 113 , for realizing the centering of the crankshaft, so that the piston of the engine cylinder is at the top dead center or the bottom dead center.

[0079] Further preferably, as Figure 9 As shown, the centering adjustment device includes a centering mark sensor 114 and a centering controller 115 . Wherein, the centering mark sensor 114 is installed on the output shaft 111 of the engine. The centering controller 115 is installed inside the housing, corresponding to the centering mark sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com