Cathode active material for lithium secondary battery and lithium secondary battery

A positive electrode active material and lithium secondary battery technology, which is applied in the direction of secondary batteries, lithium batteries, battery electrodes, etc., can solve problems such as insufficient effect, reduced capacity, and reduced structural integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] By adding Ni 0.90 co 0.08 mn 0.02 (OH) 2 , LiOH, TiO 2 and WO 3 Dry-blended and fired the mixture at 760° C. for 12 hours to prepare Ti and W-doped lithium complex transition metal oxides. In this case, TiO was used in such amounts that Ti and W reached 2000 ppm and 4000 ppm, respectively, based on the entire lithium complex transition metal oxide. 2 and WO 3 .

[0097] After combining the lithium composite transition metal oxide prepared as described above with H 3 BO 3 After mixing, the mixture was heat-treated at 350° C. for 3 hours, thereby preparing a lithium composite transition metal oxide (A) having a B-containing coating layer.

[0098] The lithium composite transition metal oxide (A) prepared as described above was mixed with carbon black conductive material and PVdF binder in a weight ratio of 96.5:1.5:2.0 in N-methylpyrrolidone solvent to prepare the positive electrode mixture, and then The positive electrode mixture was applied to one surface of a...

experiment example 1

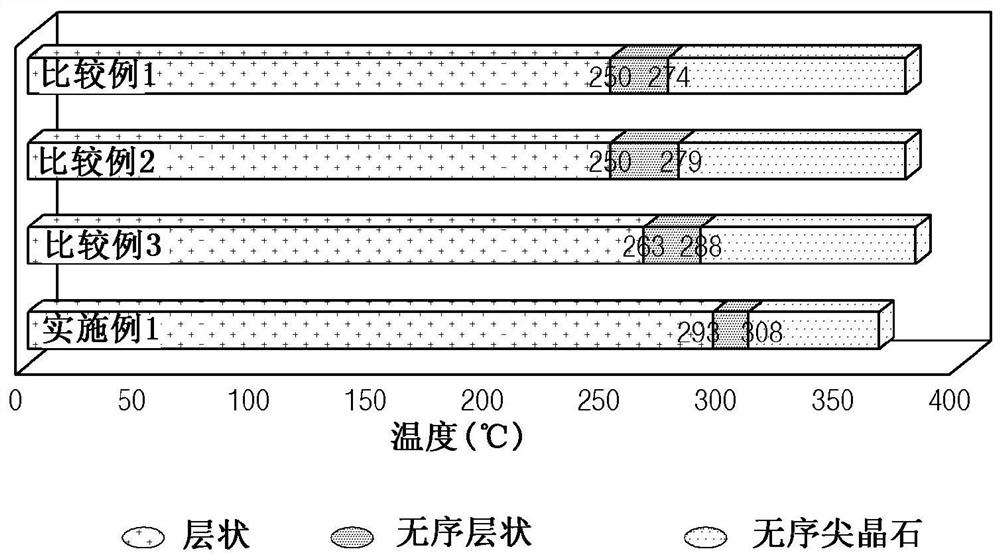

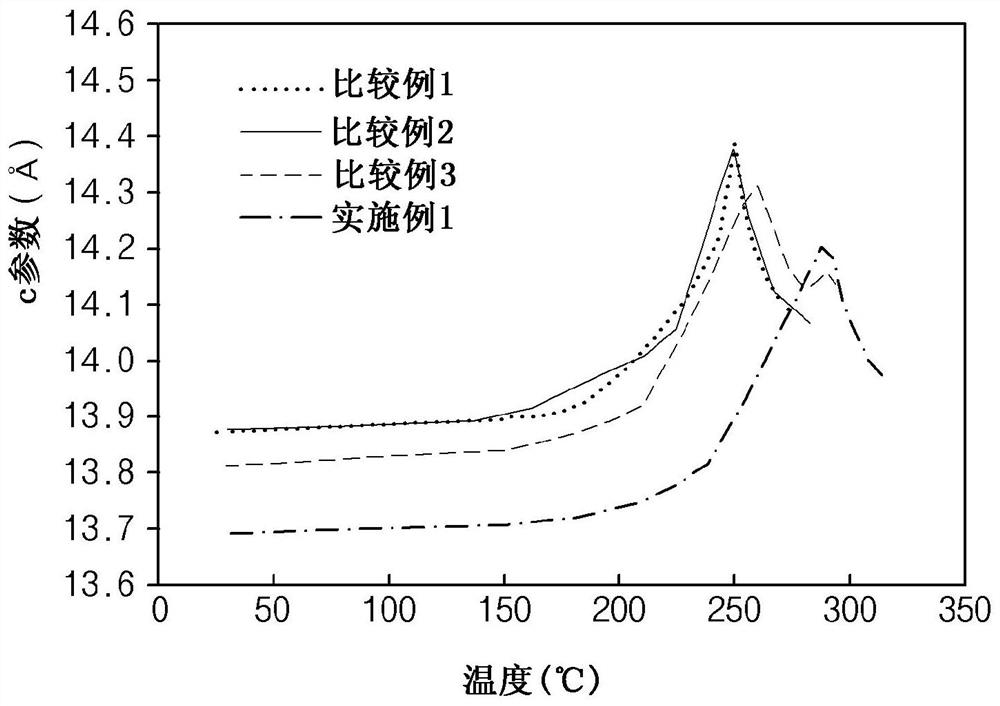

[0113] Experimental example 1: Analysis of crystal structure

[0114] At room temperature (25°C), under the condition of 0.005C cut-off, charge each lithium secondary battery of Example 1 and Comparative Examples 1 to 3 with a constant current of 0.2C until fully charged at 4.25V status. After the positive electrode was subsequently separated from the lithium secondary battery, the positive electrode active material layer was scraped off from the positive electrode, thereby collecting a positive electrode active material sample. The collected samples were placed in a radiation accelerator equipped with an in-situ high-temperature XRD instrument and analyzed by XRD, and based on the obtained data, the crystal structure and c parameter of each sample were determined as a function of temperature.

[0115] Show the measurement results in figure 1 and figure 2 middle. figure 1 is a graph showing the crystal structure of each sample as a function of temperature, and figure 2 ...

experiment example 2

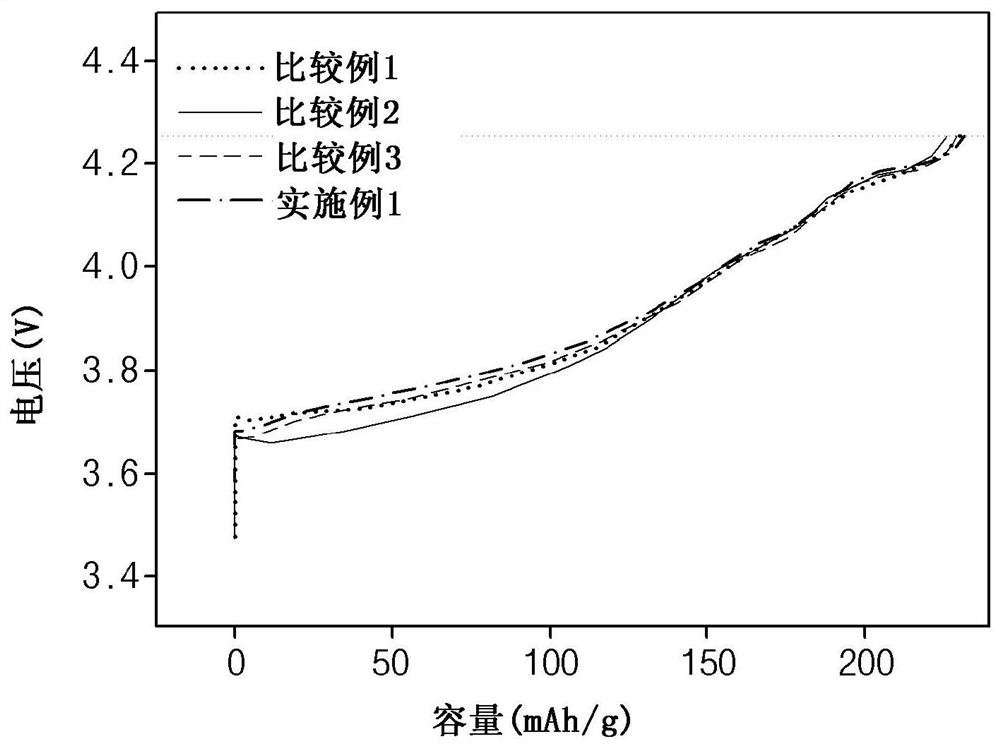

[0118] Experimental example 2: Evaluation of initial capacity characteristics

[0119] The initial capacity characteristics of the lithium secondary batteries of Example 1 and Comparative Examples 1 to 3 were evaluated by the following method:

[0120] At room temperature (25° C.), each lithium secondary battery was charged at a constant current of 0.2 C until reaching 4.25 V under a cut-off condition of 0.005 C, and maintained for 20 minutes. Subsequently, its charge capacity was measured. Show the measurement results in image 3 and in Table 1 below.

[0121] [Table 1]

[0122] Charging capacity(mAh / g) Example 1 231.44 Comparative example 1 229.90 Comparative example 2 225.91 Comparative example 3 230.61

[0123] as table 1 and image 3 As shown in , Example 1 exhibited superior capacity characteristics compared to Comparative Examples 1 to 3 despite using a positive electrode active material having a higher doping element content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com