Method for rapidly preparing iodine-potassium co-doped carbon nitride as well as product and application thereof

A carbon nitride and co-doping technology, which is applied in chemical instruments and methods, catalyst activation/preparation, chemical/physical processes, etc., can solve the problems of low separation efficiency of photogenerated electrons and holes and large band gap. Achieve the effect of improving photocatalytic efficiency, moderate bandgap width and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

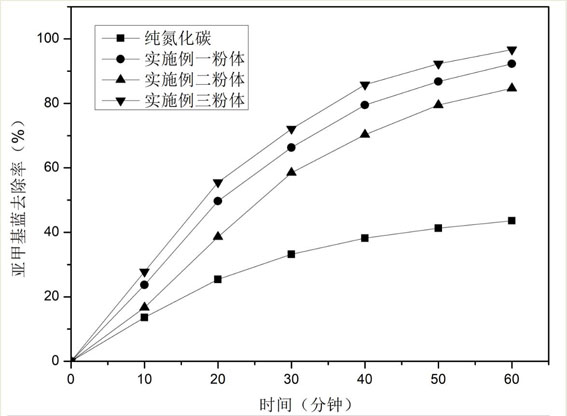

Examples

Embodiment 1

[0019] A kind of potassium iodide co-doped carbon nitride, prepared rapidly according to the following steps:

[0020] 1) Weigh melamine, potassium iodide and deionized water according to the mass ratio of melamine, potassium iodide and deionized water as 1:1:100, add melamine and potassium iodide into deionized water, stir at 80°C to evaporate to dryness into a solid;

[0021] 2) Put the solid obtained above into a ceramic crucible after being ground and pulverized, and then heat it in a muffle furnace to 550°C for 3 hours with heat preservation and roasting at a heating rate of 3°C / min, then cool naturally to obtain a brown solid;

[0022] 3) Add the brown solid obtained above into a ball mill tank, add elemental iodine and deionized water according to the mass ratio of the brown solid to iodine element and deionized water at 1:0.2:50, and put it in a planetary ball mill at 200 r / min Grinding at a rotating speed for 36 hours, then filtering, washing and drying to obtain pota...

Embodiment 2

[0025] A kind of potassium iodide co-doped carbon nitride, same as the steps of Example 1, prepared rapidly according to the following steps:

[0026] 1) Weigh melamine, potassium iodide and deionized water according to the mass ratio of melamine, potassium iodide and deionized water as 1:0.3:50, add melamine and potassium iodide into deionized water, stir at 90°C to evaporate to dryness into a solid;

[0027] 2) Put the solid obtained above into a ceramic crucible after being ground and pulverized, and then heat it in a muffle furnace to 500°C for 5 hours with heat preservation and roasting at a heating rate of 5°C / min, and then cool it naturally. The obtained brown solid is potassium and a small amount of Carbon nitride doped with iodine;

[0028] 3) Add the brown solid obtained above into a ball mill tank, add elemental iodine and deionized water according to the mass ratio of the brown solid to iodine element and deionized water at 1:0.5:100, and put it in a planetary ball...

Embodiment 3

[0031] A kind of potassium iodide co-doped carbon nitride, same as the steps of Example 1, prepared rapidly according to the following steps:

[0032] 1) Weigh melamine, potassium iodide and deionized water according to the mass ratio of melamine, potassium iodide and deionized water as 1:0.5:80, add melamine and potassium iodide into deionized water, stir at 100°C to evaporate to dryness into a solid;

[0033] 2) Grind and pulverize the solid obtained above and put it into a ceramic crucible, then heat it in a muffle furnace to 600°C for 5 hours, heat preservation and roasting at a rate of 10°C / min, and then cool it naturally. The obtained brown solid is potassium and a small amount of Carbon nitride doped with iodine;

[0034] 3) Add the brown solid obtained above into a ball mill tank, add elemental iodine and deionized water according to the mass ratio of the brown solid to iodine element and deionized water at 1:0.3:80, and put it in a planetary ball mill at 100 r / min Gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com