Fenton optimization oxidation treatment method for wastewater

A technology of oxidation treatment and treatment method, applied in oxidation water/sewage treatment, chemical instruments and methods, filtration treatment, etc., can solve problems such as waste, pH reduction, influence, etc., to reduce treatment costs, complete Fenton reaction, and operate simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

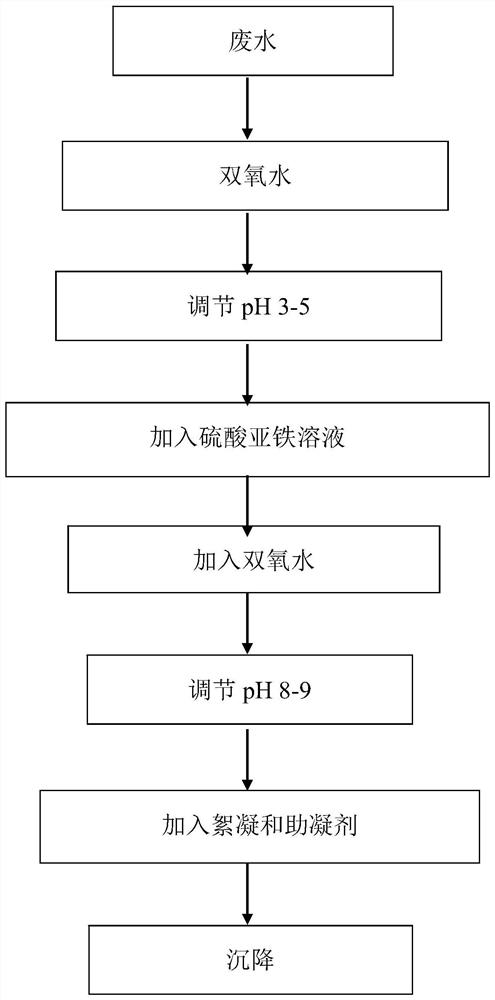

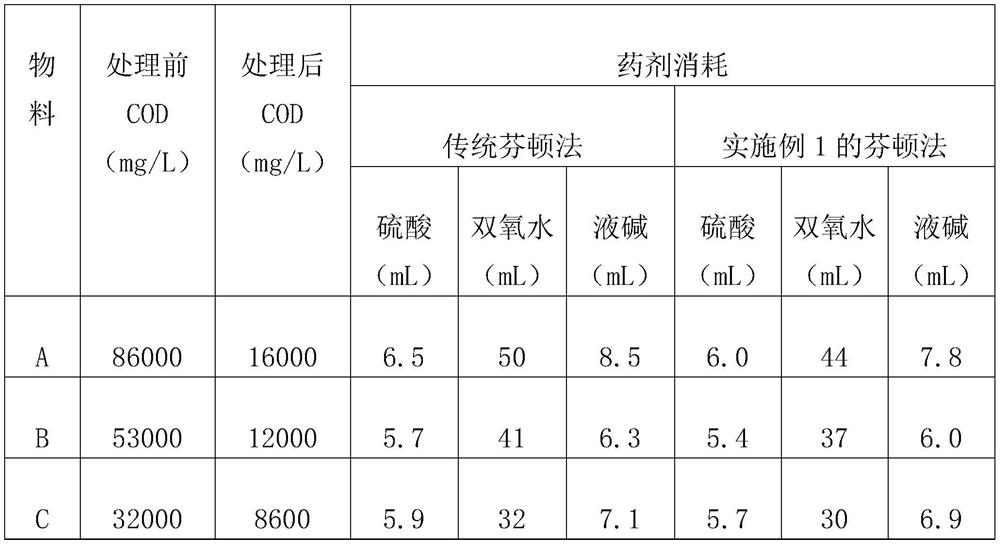

[0035] A method for Fenton optimized oxidation treatment of wastewater, the treatment method comprising the steps of:

[0036] Add hydrogen peroxide to the waste water for reaction. After 30 minutes of reaction, since the concentration of waste water that can be oxidized by hydrogen peroxide is very low at this time, the reaction rate drops significantly. Let the residual hydrogen peroxide react with the waste water material for 30 minutes. After the reaction is completed, adjust the pH to 3. -4, and add ferrous sulfate solution (the mass concentration of ferrous sulfate is 20%) and stir for 4 minutes;

[0037] Afterwards, hydrogen peroxide was added again for reaction. During the reaction, the pH was controlled to be not lower than 2, and the temperature was not higher than 45 degrees Celsius. After reacting for 1 hour, an aqueous solution of sodium hydroxide (30% in mass concentration) was added to adjust the pH to 8-9, and then added Aluminum chloride and polyacrylamide wer...

Embodiment 2

[0044] A method for Fenton optimized oxidation treatment of wastewater, the treatment method comprising the steps of:

[0045]Add hydrogen peroxide to the wastewater for reaction. After 80 minutes of reaction, the concentration of wastewater that can be oxidized by hydrogen peroxide is very low at this time, so the reaction rate drops significantly. Let the residual hydrogen peroxide react with the wastewater material for 120 minutes. After the reaction is completed, adjust the pH to 3. -4, and add ferrous sulfate solution (the mass concentration of ferrous sulfate is 25%) and stir for 15 minutes;

[0046] Afterwards, hydrogen peroxide was added again for reaction. During the reaction, the pH was controlled to be not lower than 2, and the temperature was not higher than 45 degrees Celsius. After reacting for 3 hours, an aqueous solution of potassium hydroxide (30% in mass concentration) was added to adjust the pH to 8-9, and then added Alum and bentonite are allowed to settle ...

Embodiment 3

[0051] A method for Fenton optimized oxidation treatment of wastewater, the treatment method comprising the steps of:

[0052] Add hydrogen peroxide to the waste water for reaction. After 45 minutes of reaction, since the concentration of waste water that can be oxidized by hydrogen peroxide is very low at this time, the reaction rate drops significantly. Let the residual hydrogen peroxide react with the waste water material for 45 minutes. After the reaction is completed, adjust the pH to 3. -4, and add ferrous sulfate solution (the mass concentration of ferrous sulfate is 20%) and stir for 6 minutes;

[0053] Then add hydrogen peroxide again to react. During the reaction, the pH is controlled to be not lower than 2, and the temperature is not higher than 45 degrees Celsius. After reacting for 1.5 hours, add calcium hydroxide aqueous solution (mass concentration is 30%) to adjust the pH to 8-9, and then add Basic aluminum chloride and diatomaceous earth, settling for 45 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com