Re-strengthening method for chemical cold-bending thinned surface of aluminosilicate cover plate glass

A cover glass and aluminosilicate technology, which is applied in the field of re-strengthening of chemical cold-bending thinned surface of aluminosilicate cover glass, can solve the problem that glass is not easy to be formed by hot bending.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

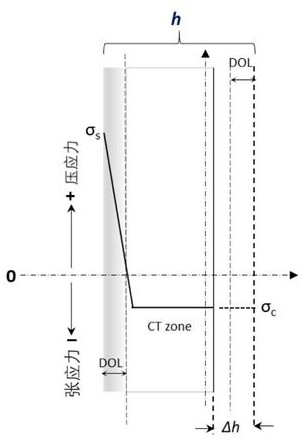

Method used

Image

Examples

Embodiment 1

[0161] Effect of heat treatment on CS and DOL on the surface of chemically strengthened glass and the effect of chemical strengthening again:

[0162] This example uses the high-alumina cover glass of Rainbow Special Glass, model Irico CG-01, with a thickness of 1.0mm; uses a standardized strong furnace with built-in potassium nitrate (purity above 99%), the strengthening temperature is 400 ° C, and the temperature holding time is 4 hours After chemical strengthening, use the FSM-6000LE surface stress meter of Orihara Manufacturing Co., Ltd. to measure DOL and CS. The size of the glass sample is 50mmx50mm, and the thickness is 1.0mm. All the glass samples are edge-treated and the edge micro-cracks are eliminated as much as possible. After finishing, the glass sheets are cleaned and dried, and then placed in a chemical strengthening furnace for chemical strengthening.

[0163] During the chemical strengthening process, the glass is soaked in molten potassium nitrate at 400 ° C....

Embodiment 2

[0172] Effects of heat treatment and re-ion exchange on surface compressive stress (CS) and depth of stress layer (DOL) of cold-bent curved glass:

[0173] In this example, the high-alumina cover glass of Rainbow Special Glass, model Irico CG-01, with a thickness of 0.7mm is used; potassium nitrate (purity above 99%) is built in a standardized strong furnace, the strengthening temperature is 400°C, and the temperature holding time is 4 hours After chemical strengthening, use the FSM-6000LE surface stress meter of Orihara Manufacturing Co., Ltd. to measure DOL and CS. The size of the glass sample is 130mmx70mm, and the thickness is 0.7mm. All the glass samples are edge treated and the edge micro-cracks are eliminated as much as possible. After finishing, the glass sheets are cleaned and dried first, and then placed in a chemical strengthening furnace for chemical strengthening.

[0174] During the chemical strengthening process, the glass is soaked in molten potassium nitrate a...

Embodiment 3

[0179] Effects of heat treatment and re-chemical ion exchange on the bow height of high-alumina glass after chemical cold bending:

[0180] In this example, the high-alumina cover glass of Rainbow Special Glass, model Irico CG-01, with a thickness of 0.7mm is used; potassium nitrate (purity above 99%) is built in a standardized strong furnace, the strengthening temperature is 400°C, and the temperature holding time is 4 hours After chemical strengthening, use the FSM-6000LE surface stress meter of Orihara Manufacturing Co., Ltd. to measure DOL and CS. The size of the glass sample is 130mmx70mm, and the thickness is 0.7mm. All the glass samples are edge treated and the edge micro-cracks are eliminated as much as possible. After finishing, the glass sheets are cleaned and dried first, and then placed in a chemical strengthening furnace for chemical strengthening.

[0181] During the chemical strengthening process, the glass is soaked in molten potassium nitrate at 400 ° C. Durin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com