Polyhedral oligomeric silsesquioxane nucleating agent as well as preparation method and application thereof

A technology of silsesquioxane and nucleating agent, which is applied in the field of cage-type silsesquioxane nucleating agent and its preparation, can solve the problems of anti-aging performance, weather resistance, light and heat resistance, product gloss and transparency Good, long molding processing cycle, slow crystallization speed and other problems, to achieve the effect of improving nucleation efficiency and its processing performance, nucleation efficiency, and crystallization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

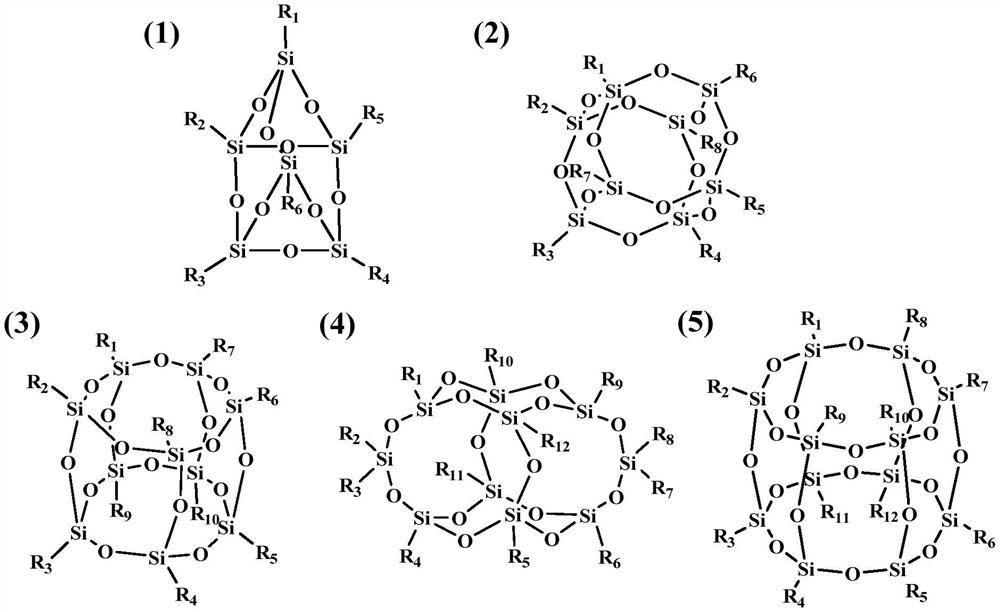

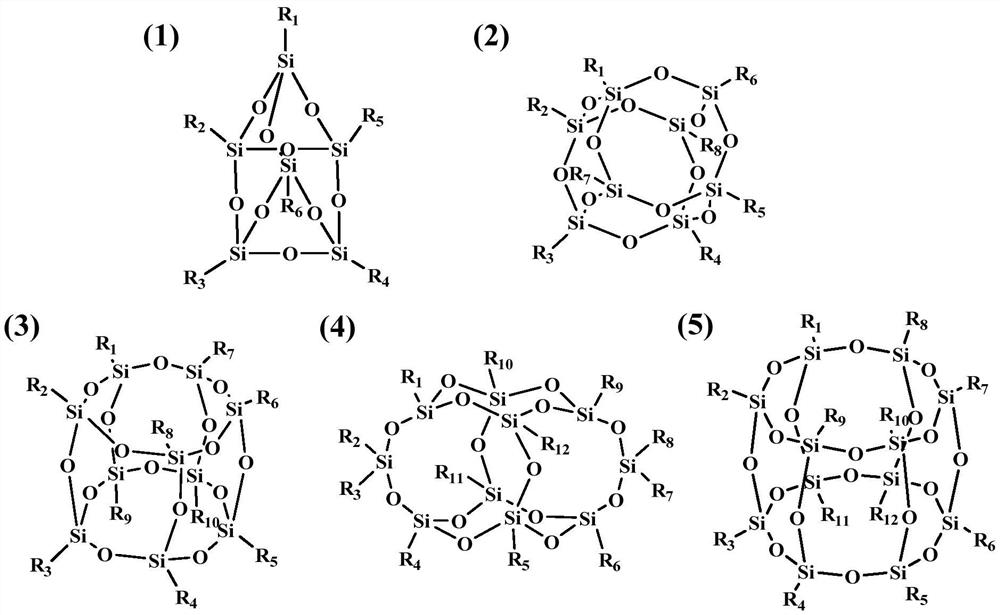

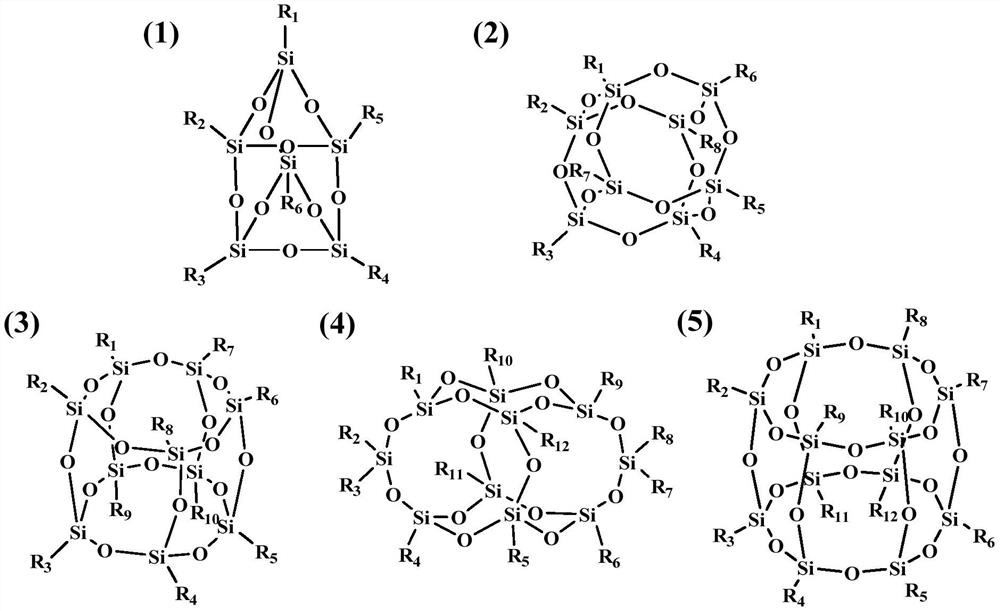

Image

Examples

Embodiment 1

[0039] A preparation method of cage type silsesquioxane nucleating agent comprises the following steps:

[0040] Cage silsesquioxane (9.72 g, 0.01 mol) of the structure shown in formula 2 (the structure is shown below, purchased from American hybrid plastics company, the product number is CA0295) and calcium oxide (0.2 g, 0.02 mol) were molar Disperse in 100mL tetrahydrofuran solution at a ratio of 1:2, and heat to reflux for 8 hours at a temperature of 70°C. The mixture of the two was dried at 100° C. for 24 hours, and passed through a 200-mesh sieve to obtain the cage-type silsesquioxane nucleating agent.

[0041] R 1-7 For cyclohexyl, R 8 for

[0042] A kind of preparation method of modified polypropylene comprises the following steps:

[0043]0.1 parts by weight of the cage-type silsesquioxane nucleating agent, 0.1 parts by weight of antioxidant 1010, 0.1 part by weight of antioxidant 168, and 99.7 parts by weight of homopolypropylene were melt-mixed and extruded on ...

Embodiment 2

[0045] A preparation method of cage type silsesquioxane nucleating agent comprises the following steps:

[0046] Massage cage-type silsesquioxane (9.72g, 0.01mol) with the structure shown in formula 2 (the structure is shown below, purchased from American hybrid plastics company, product number is CA0296) and zinc hydroxide (1.98g, 0.02mol) Disperse in 100mL acetone solution at a molar ratio of 1:2, and heat to reflux for 8 hours at a temperature of 70°C. The mixture of the two was dried at 100° C. for 24 hours, and passed through a 400-mesh sieve to obtain the cage-type silsesquioxane-based nucleating agent.

[0047] Among them, R 1-7 Both are isobutyl, R8 is

[0048] A kind of preparation method of modified polypropylene comprises the following steps:

[0049] 0.2 parts by weight of the cage-type silsesquioxane nucleating agent, 0.1 parts by weight of antioxidant 1010, 0.1 part by weight of antioxidant 168, and 99.6 parts by weight of homopolypropylene were melt-mixed a...

Embodiment 3

[0051] A preparation method of cage type silsesquioxane nucleating agent comprises the following steps:

[0052] Cage silsesquioxane with structure shown in Formula 2 (structure shown below, purchased from American hybrid plastics company, article number is CA0298) (16.57g, 0.01mol) and sodium hydroxide (3.2g, 0.08mol) were massaged Disperse in 100mL tetrahydrofuran solution at a molar ratio of 1:8, and heat to reflux for 8 hours at a temperature of 70°C. The mixture of the two was dried at 100° C. for 24 hours, and passed through a 200-mesh sieve to obtain the cage-type silsesquioxane nucleating agent.

[0053] Among them, R 1-8 both

[0054] A kind of preparation method of modified polypropylene comprises the following steps:

[0055] 0.2 parts by weight of the cage-type silsesquioxane nucleating agent, 0.1 parts by weight of antioxidant 1010, 0.1 part by weight of antioxidant 168, and 99.6 parts by weight of homopolypropylene were melt-mixed and extruded on a twin-scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com