Preparation method of titanium nitride coating, base material and application

A titanium coating and titanium nitride technology, which is applied in the field of preparation of titanium nitride coatings, can solve the problems affecting the hardness and wear resistance of TiN coatings, and achieve the effect of improving the nitriding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

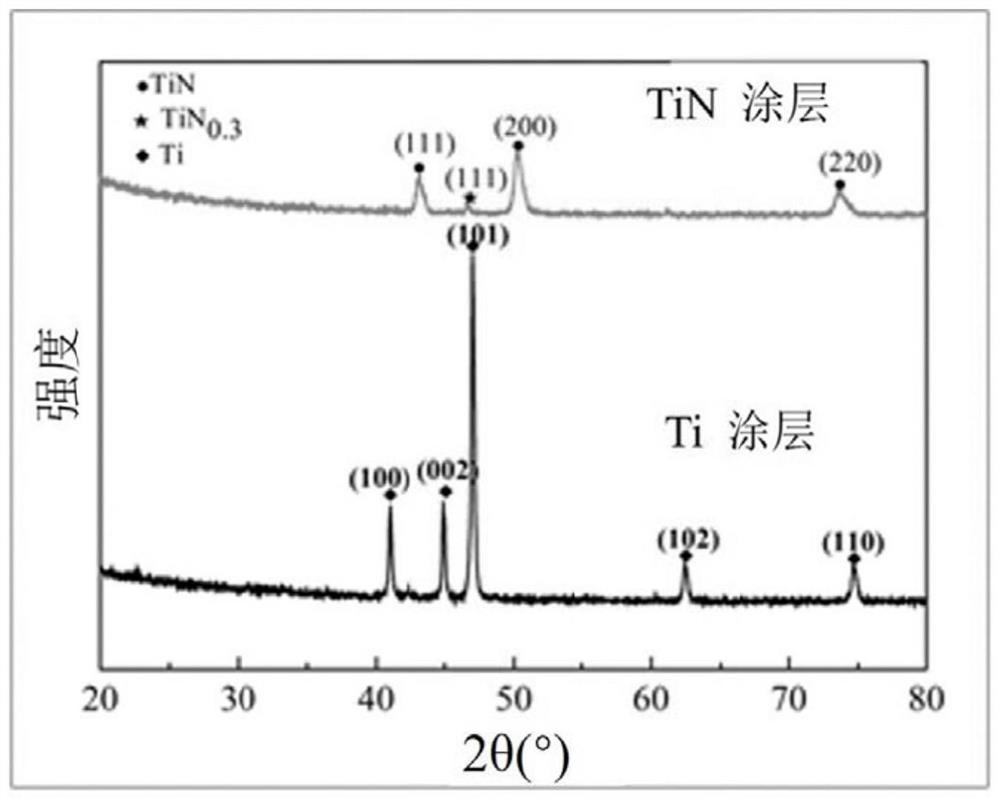

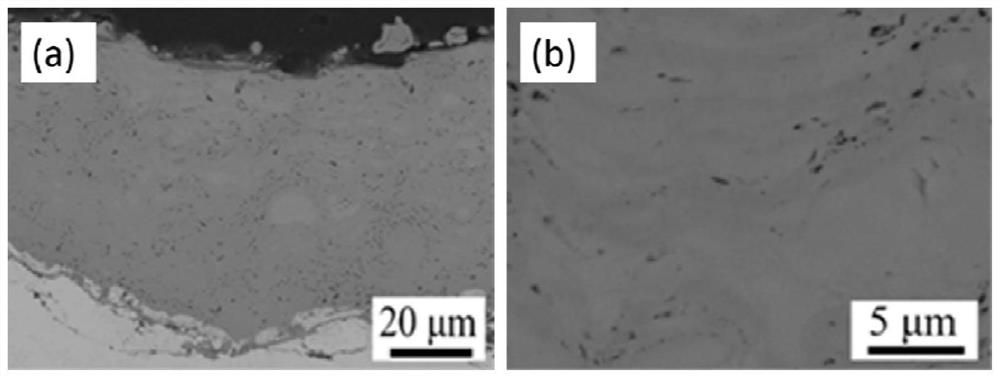

[0039]Some embodiments of the present invention provide a method for preparing a titanium nitride coating, which includes: performing low-pressure plasma spraying on the surface of the substrate for the first time to form a titanium-containing coating on the surface of the substrate. The titanium-containing coating is titanium Coating or titanium nitride coating; the titanium coating is subjected to a second low-pressure plasma spraying of nitrogen to nitride the titanium coating.

[0040] The nitriding rate of the titanium nitride coating prepared by low-pressure plasma spraying is creatively improved through the above technical scheme, so that the operation is simple, fast and economical, and the prepared coating is dense and pure. The reason may be that the titanium coating is sprayed by low-pressure plasma first, and then the titanium coating is sprayed again by low-pressure plasma spraying. Both processes are carried out by low-pressure plasma spraying, and the operation i...

Embodiment 1

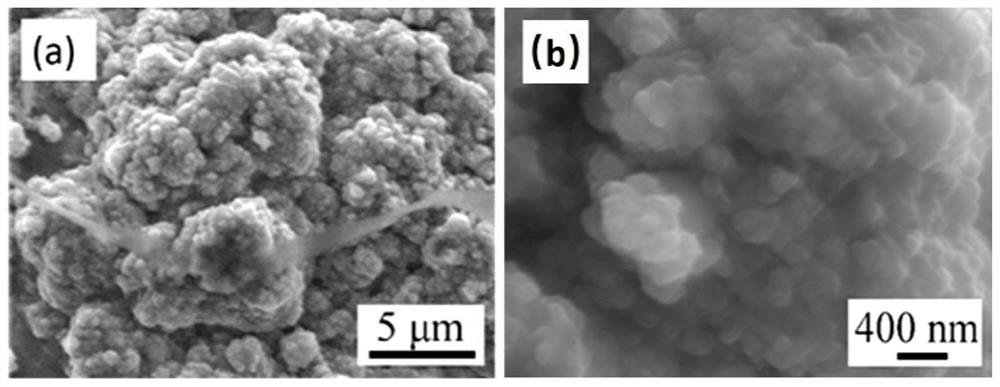

[0064] (1) Choose stainless steel as the substrate, use 60#SiC to polish the surface, and then use Al 2 o 3 Sandblasting is performed until the surface roughness is Ra=3-4μm, and then ultrasonic cleaning is performed with alcohol. Put 400g, 7-23μm spherical Ti powder into the powder feeder.

[0065] (2) Put the stainless steel substrate into the vacuum chamber and close the hatch of the low-pressure plasma equipment, and extract the vacuum to a pressure of 0.2mbar.

[0066] (3) Fill the gun with Ar to 43mbar, then evacuate the gun to a pressure of 1mbar, preheat the substrate with a plasma jet, and detect the substrate temperature with an infrared thermometer until the substrate temperature reaches 700°C.

[0067] (4) Adjust plasma spraying parameters to prepare titanium coating: spraying pressure is 1.5mbar; spray gun power is 51kW, current is 650A; working gas flow rate is Ar: 45splm, H 2 : 12slpm. After the flame flow is stable, the Ti powder is fed into the plasma flam...

Embodiment 2

[0071] (1) Use stainless steel as the substrate, 60#SiC to polish the surface, and then use Al 2 o 3 Sandblasting is carried out until the surface roughness is Ra=3-4 μm. Put 400g, 7-23μm spherical Ti powder into the powder feeder.

[0072] (2) Put the stainless steel substrate into the vacuum chamber and close the hatch of the low-pressure plasma equipment, and extract the vacuum to a pressure of 0.2mbar.

[0073] (3) Fill the gun with Ar to 43mbar and then ignite the gun. After the gun is evacuated to a pressure of 1mbar, the substrate is preheated by the plasma flame flow, and the substrate temperature is detected by an infrared thermometer until the substrate temperature reaches 750°C.

[0074] (4) Adjust plasma spraying parameters to prepare titanium nitride coating: spraying pressure is 1.5mbar; spray gun power is 54kW, current is 750A; working gas flow rate is Ar: 45splm, H 2 : 12slpm; N 2 : 4slpm; After the flame flow is stable, inject Ti powder into the plasma fla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com