Method of preparing titanium coating through atmosphere supersonic plasma spraying based on gas protection

A supersonic plasma, gas shielding technology, applied in coating, metal material coating process, melt spraying, etc., can solve the problem of high oxide and nitride content in titanium coating, difficulty in controlling spraying speed, and coating bonding strength. To achieve the effect of low porosity, short residence time and small spraying distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

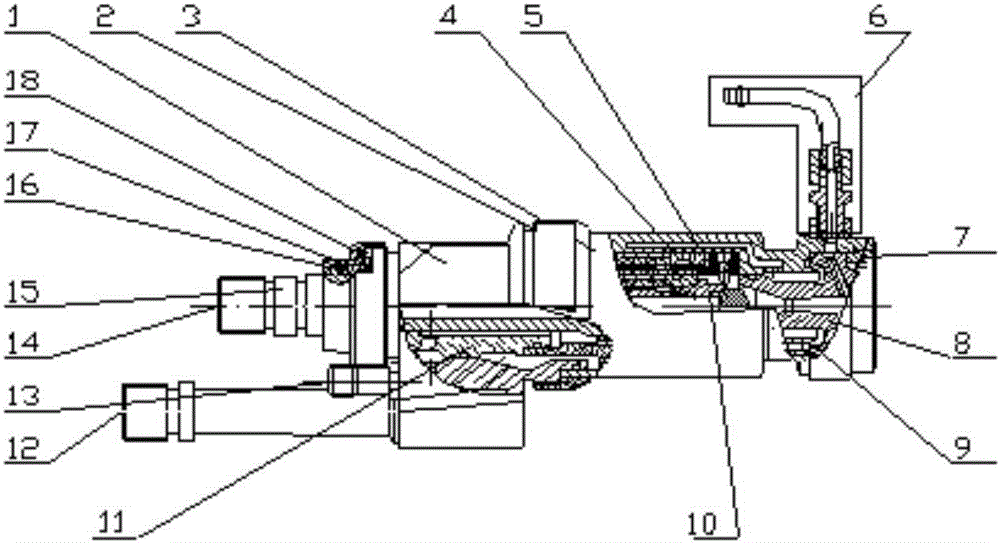

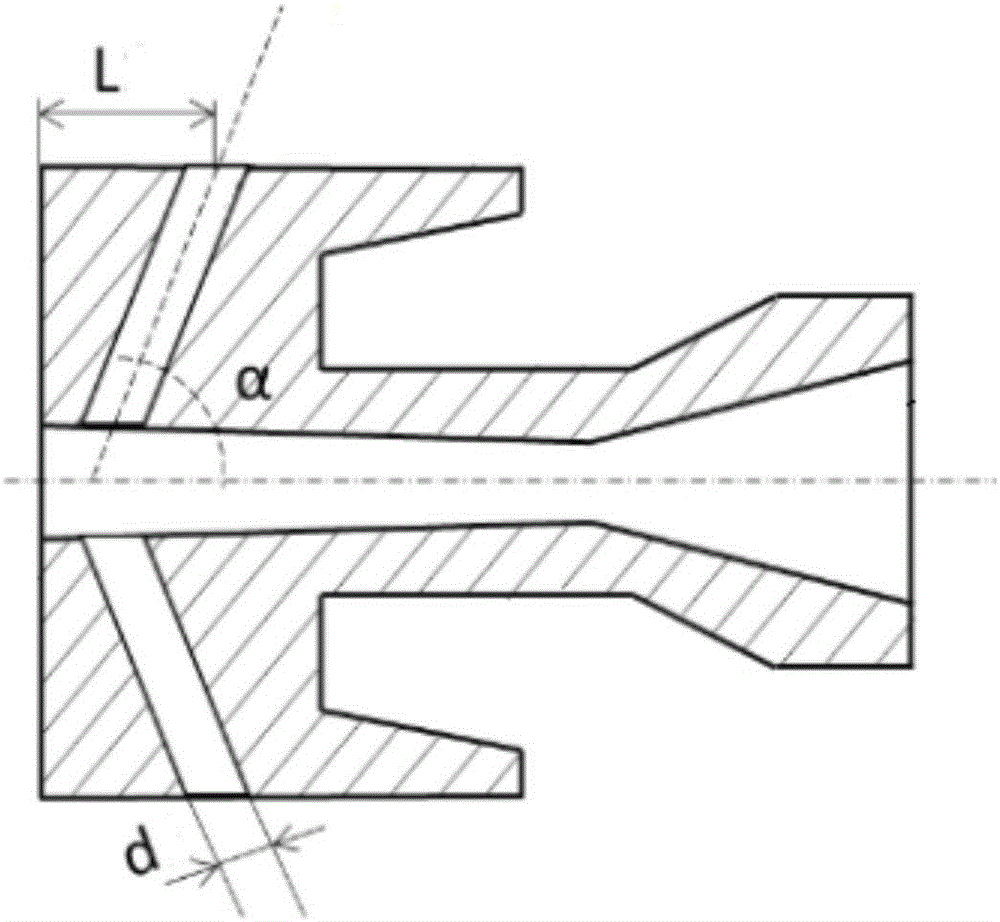

[0062] use as figure 2 The radial protective gas anode nozzle provided prepares a pure titanium coating on an aluminum alloy substrate, and the specific steps are as follows:

[0063] (1) An aluminum alloy with a size of 60×25×5 mm is prepared as a substrate for preparing a titanium coating.

[0064] (2) Use alcohol and ultrasonic cleaning to clean the surface of the substrate to remove oil and impurities.

[0065] (3) Use a press-in sandblasting machine to roughen the surface of the substrate by sandblasting, and the sand grains are 24# white corundum sand. The blasting distance is 150mm.

[0066] (4) Fix the substrate in front of the spray gun. During spraying, the manipulator operates the atmospheric supersonic plasma spray gun to move and scan the substrate quickly in a "well" shape, and form a titanium coating on the substrate after 30 rounds.

[0067] Among them, the relevant parameters of the spraying process are as follows:

[0068] On the nozzle of the original hig...

Embodiment 2

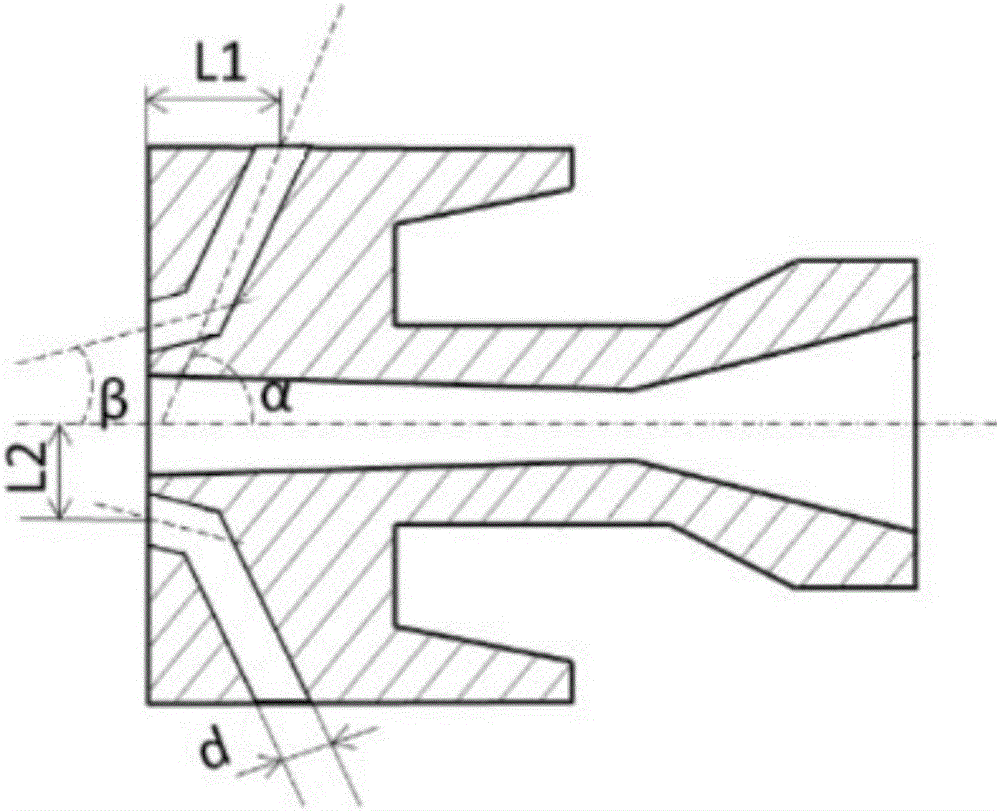

[0086] Compared with embodiment 1, adopt as image 3 The axial shielding gas nozzles shown have shielding gas holes according to the following dimensions:

[0087] L1=8.5mm, L2=3mm, α=55°, β=15°, d1=2.2mm.

[0088] Correspondingly in figure 1 The shown 6 powder feeding racks are drilled in the corresponding direction, and 9 diversion structures are installed, and connected with Ar gas.

[0089] The parameters of shielding gas during spraying are:

[0090] Pressure 1MPa, flow rate 50L / min.

[0091] Other parameters are the same as in Example 1.

[0092] The cross-section of titanium coating prepared by axial shielding gas nozzle is as follows: Figure 6 shown. The porosity of the coating is slightly higher than that of the titanium coating prepared by the radial shielding gas nozzle, and the oxygen content is 0.2 . The shielding gas shield that illustrates the performance of the axial shielding gas nozzle can also reduce the oxidation and nitriding of titanium particles,...

Embodiment 3

[0094] Compared with Example 2, let L2=2.5mm, β=0°, and other parameters are the same as Example 2. At this time, the shielding gas is ejected from the nozzle along the axial direction of the jet, and a protective gas shield is formed outside the jet. The nozzle structure Such as Figure 7 shown.

[0095] The parameters of shielding gas during spraying are:

[0096] The pressure is 1.3MPa and the flow rate is 80L / min.

[0097] Other parameters are the same as in Example 1.

[0098] use Figure 7 The titanium coating section prepared by the axial shielding gas nozzle is as follows Figure 8 shown. The porosity of the coating is comparable to that of the titanium coating prepared in Example 2, and the oxygen content is 0.2 . The shielding gas shield that illustrates the performance of the axial shielding gas nozzle can also reduce the oxidation and nitriding of titanium particles, but the effect is lower than that of the radial shielding gas nozzle.

[0099] Analyze accor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com