Method for preparing multidimensional photocatalytic material

A technology of catalytic material and photocatalytic film, which is applied in the field of photocatalytic material preparation, can solve the problems of unstable plating solution, insufficient film binding force, uneven distribution, etc., and achieve improved photocatalytic performance, improved corrosion resistance, and corrosion resistance. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

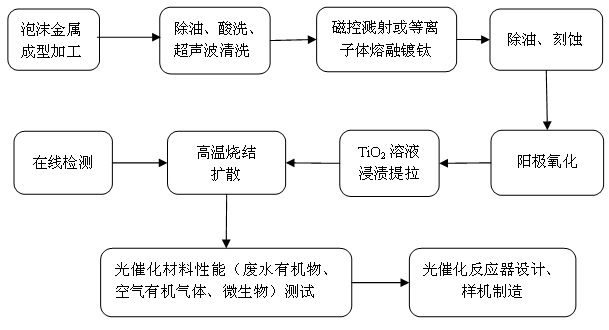

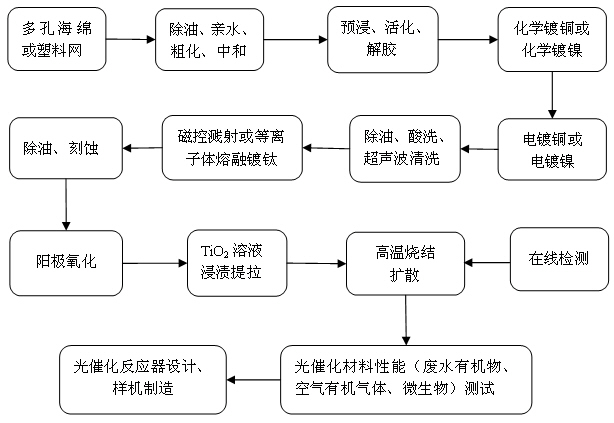

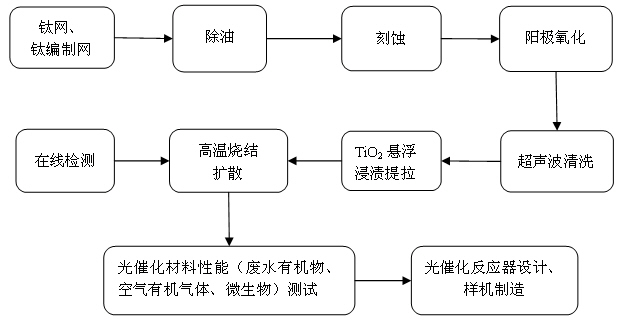

Embodiment 1

[0045] Embodiment 1: titanium dioxide / titanium / copper foam (abbreviation: TiO 2 / Ti / CF, where CF means copper foam) and titanium dioxide / titanium / brass foam (abbreviation: TiO 2 / Ti / BF, where BF stands for brass foam) series. Put copper foam or brass foam with a size of 10×5cm, a thickness of 0.5cm, and 20PPI in a sodium hydroxide (mass fraction: 4%) degreasing solution, degreasing at 50°C for 5 minutes, remove the grease on the surface, and wash with water; In 5% dilute sulfuric acid solution, pickle at 30°C for 1min, remove the oxide film on the surface, and wash with water; then ultrasonically clean with acetone, ethanol, and distilled water, and wash at 25°C for 10min; -0.05mm; in 4% sodium hydroxide solution, degreasing at 50°C for 5 minutes, washing with water; in etching solution containing 1% dilute nitric acid and 2% hydrofluoric acid, etch at room temperature for 10 seconds, remove Surface TiO 2 , washed with water; in the anodic oxidation solution containing 1...

Embodiment 2

[0046] Embodiment 2: titanium dioxide / titanium / nickel foam (abbreviation: TiO 2 / Ti / NF, where NF stands for nickel foam) and titanium dioxide / titanium / iron foam (abbreviation: TiO 2 / Ti / FF, where FF means ferrum foam) series. Put nickel foam or iron foam with a size of 10×5cm, a thickness of 0.5cm, and 25PPI in a degreasing solution prepared with a degreasing powder with a mass fraction of 6%, degreasing at 50°C for 5 minutes, remove the grease on the surface, and wash with water; In a 2% dilute sulfuric acid solution, pickle at 30°C for 1min to remove the oxide film on the surface, and wash with water; then ultrasonically clean with acetone, ethanol, and distilled water, and wash at 25°C for 10min; 0.01-0.05mm; in the degreasing solution prepared with 6% degreasing powder, degreasing at 50°C for 5 minutes, and washing with water; in the etching solution containing 1% dilute nitric acid and 2% hydrofluoric acid mixture, Etching at room temperature for 10s to remove TiO on th...

Embodiment 3

[0047] Embodiment 3: titanium dioxide / titanium / aluminum foam (abbreviation: TiO 2 / Ti / AF, where AF stands for aluminum foam) series. Put aluminum foam with a size of 10×5cm, a thickness of 0.5cm, and 25PPI in a sodium hydroxide (mass fraction: 4%) degreasing solution, degreasing at 50°C for 5 minutes, remove the grease on the surface, and wash with water; in 10% dilute In hydrochloric acid solution, pickle at 30°C for 1min, remove the oxide film on the surface, and wash with water; sequentially undergo ultrasonic cleaning with acetone, ethanol, and distilled water, and wash at 25°C for 10min; use magnetron sputtering to coat titanium with a film thickness of 0.01-0.05mm; In 4% sodium hydroxide solution, degreasing at 50°C for 5 minutes and washing with water; in an etching solution containing 1% dilute nitric acid and 2% hydrofluoric acid mixture, etch at room temperature for 10 seconds to remove TiO on the surface 2 , washed with water; in the anodic oxidation solution conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com