Vegetable protein vegetarian jerky and processing method thereof

A plant protein and processing method technology, which is applied in the field of deep processing of plant protein products, can solve the problems of waste of resources, low moisture content, etc., and achieve the effects of reducing waste, low production cost, and good sensory quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment provides a kind of vegetable protein jerky, and its processing method is as follows:

[0040] (1) Mixing and flavoring: Put 5500g soybean protein isolate, 2000g gluten powder, 1000g soybean protein powder, 500g corn starch, 500g brewed soy sauce, 400g white sugar, 100g salt, 150g five-spice powder, 50g yeast extract and 1000g water. Mix in a blender;

[0041] (2) Low-humidity extrusion: Put the uniformly mixed material into a twin-screw extruder for extrusion. During the extrusion process, the moisture content of the material is controlled below 20%. The extrusion temperature is 70°C in the first zone and 100°C in the second zone. The temperature in the third zone is 140°C, and the fourth zone is 180°C. The extrusion time is about 90s. The extruded material is molded and cut by a cutter at a speed of 1s / time;

[0042] (3) Cooling: the dried vegetarian meat blank after cutting is cooled to room temperature;

[0043] (4) Frying: Put the cooled vegetarian...

Embodiment 2

[0049] This embodiment provides a kind of vegetable protein jerky, and its processing method is as follows:

[0050] (1) Mixing and flavoring: Put 6000g soybean protein isolate, 1500g gluten powder, 500g soybean protein powder, 400g corn starch, 300g brewed soy sauce, 500g white sugar, 150g salt, 100g five-spice powder, 100g yeast extract and 1200g water Mix in a blender;

[0051] (2) Low-humidity extrusion: Put the uniformly mixed material into a twin-screw extruder for extrusion. During the extrusion process, the moisture content of the material is controlled below 20%. The extrusion temperature is 85°C in the first zone and 110°C in the second zone. The temperature in the third zone is 130°C, and the fourth zone is 170°C. The extrusion time is about 120s. The extruded material is molded and cut by a cutter at a speed of 1s / time;

[0052] (3) Cooling: the dried vegetarian meat blank after cutting is cooled to room temperature;

[0053] (4) Frying: Put the cooled vegetarian...

experiment example 1

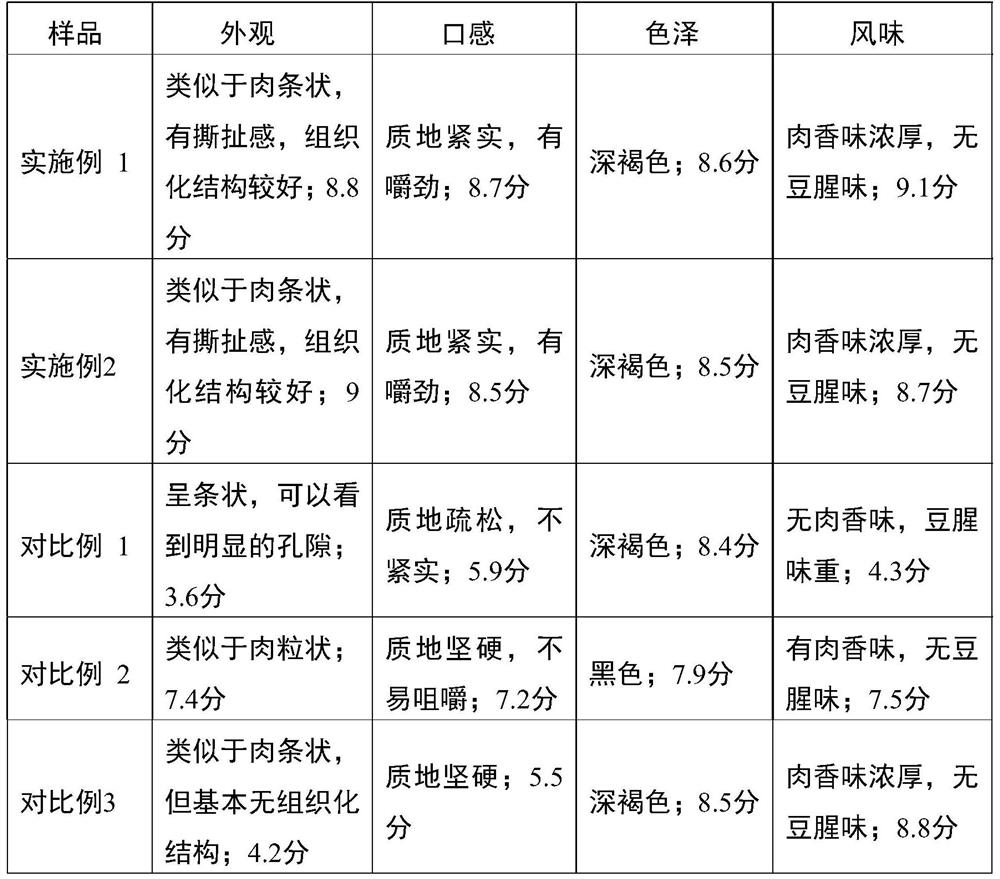

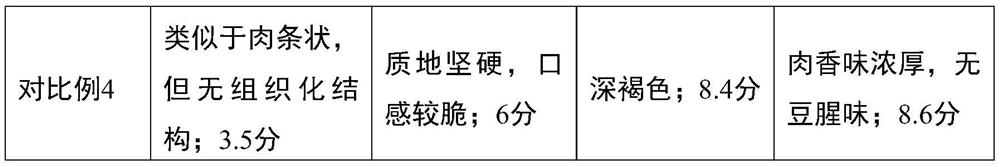

[0067] Taking the samples of the above examples and comparative examples, 20 sensory evaluators were invited to perform sensory evaluation on the samples from the four aspects of appearance, mouthfeel, color and flavor. The sensory evaluation results are shown in Table 1.

[0068] Each embodiment of table 1 and the sensory evaluation result of comparative example vegetarian jerky

[0069]

[0070]

[0071] It can be seen from Table 1 that the appearance of the vegetable protein jerky provided by the embodiment of the present invention is more similar to the original cut jerky, and has a strong tearing feeling, a better texture, a firm texture, and a chewy texture. The color is similar to that of jerky, and the meat has a strong flavor without beany smell; in comparative example 1, the commercially available tissue protein was rehydrated and processed into jerky, the tissue was looser, and obvious pores could be seen, more similar to For the Latiao product, there is no fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com