Construction method for reducing surface bubbles of aluminum alloy formwork concrete

A technology for aluminum alloy formwork and concrete surface, which is applied to formwork/formwork components, petroleum industry, manufacturing tools, etc., can solve the problems of dark bubbles on the concrete surface, affecting the aesthetics of the concrete surface, etc., and achieves a simple preparation method and low cost. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

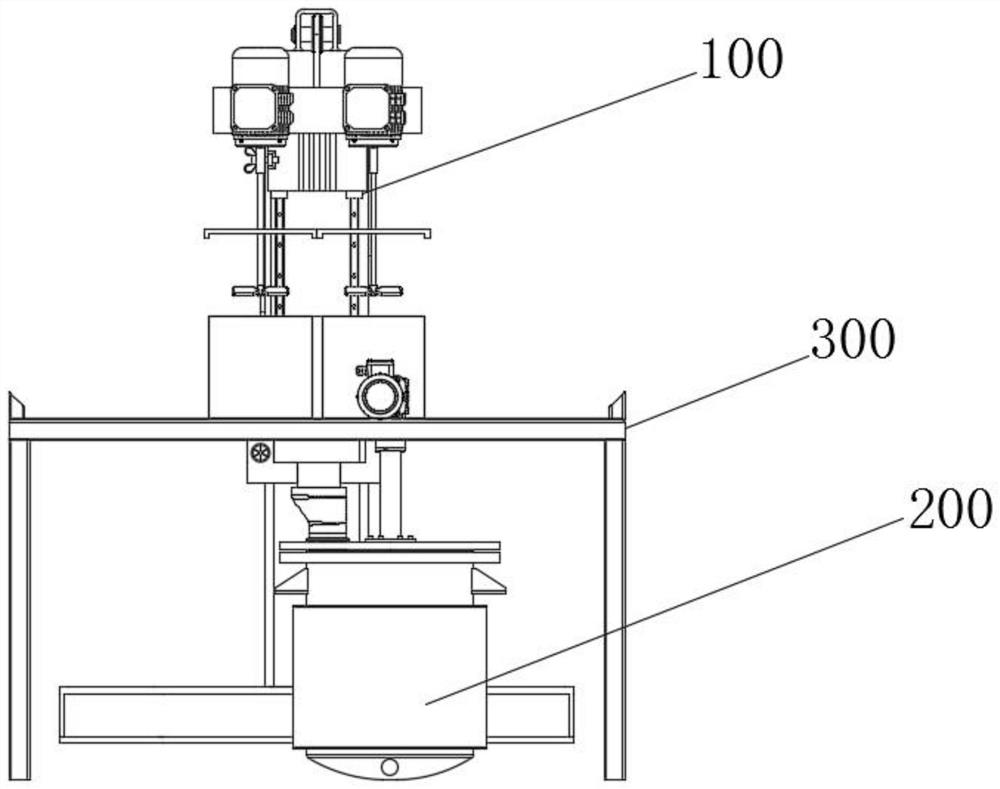

[0043]SeeFigure 1-9As shown, this embodiment is a construction method for reducing air bubbles on the surface of aluminum alloy formwork concrete, which includes the following steps:

[0044]Step 1. Prepare the bubble elimination release agent:

[0045]S1: Add Tween20, sodium dodecyl sulfonate, and water by weight to one of the mixing tanks of the solution mixing device, and add simethicone and sorbitan monolaurate to the other by weight to mix In the slot

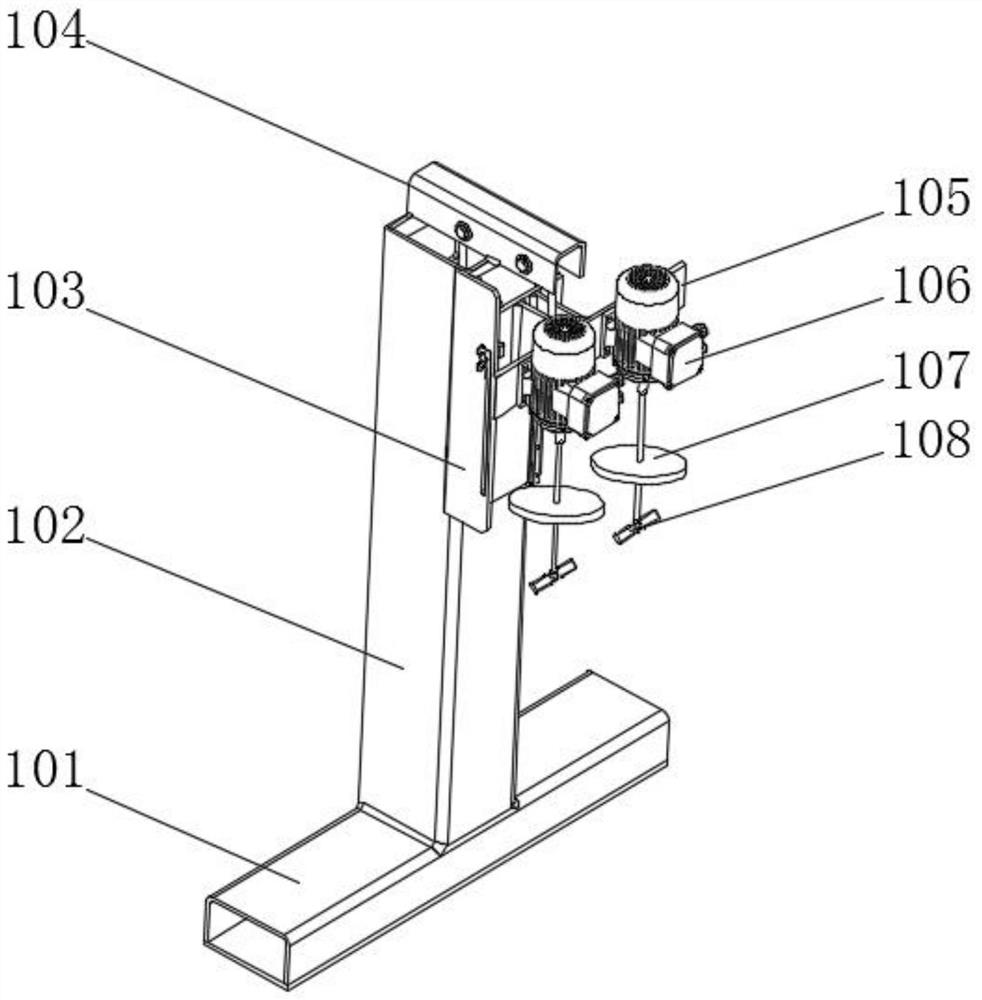

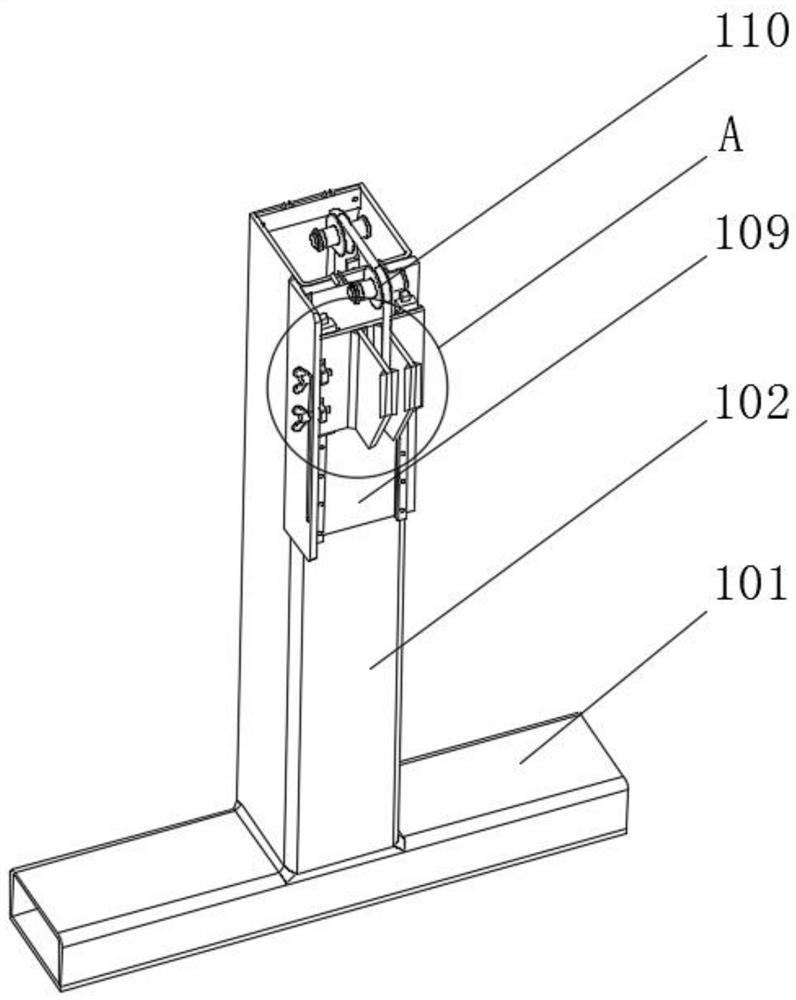

[0046]S2: Start the drive motor. The drive motor drives the winding roller to rotate through the driving pulley and the driven pulley to release the rope. The guide pulley drives the T-shaped splint to slide down on the slide rail, thereby driving the mounting plate, The height of the first mixing motor is lowered, so that the two first mixing blades respectively enter the inner cavities of the two mixing tanks, and the two sealing covers are respectively covered on the two mixing tanks;

[0047]S3: Start the first mixing motor. The operati...

Embodiment 2

[0057]The difference between this embodiment and embodiment 1 is that the bubble elimination mold release agent is prepared from the following parts by weight:

[0058]30 parts of dimethyl silicone oil, 0.15 parts of sorbitan monolaurate, 0.20 parts of Tween 20, 0.06 parts of sodium lauryl sulfonate, 1.0 parts of compound modification components, 70 parts of water.

[0059]The compound modified additive includes the following components by weight:

[0060]0.4 part of tributyl phosphate, 0.25 part of ethyl paraben, 0.1 part of pH regulator, 0.2 part of thickener, 0.15 part of metal ion shielding agent;

[0061]Wherein, the pH regulator is a sodium hydroxide solution with a mass concentration of 6%, the thickener is a carboxymethyl cellulose solution with a mass concentration of 3.5%, and the metal ion shielding agent is EDTA.

Embodiment 3

[0063]The difference between this embodiment and embodiment 1 is that the bubble elimination mold release agent is prepared from the following parts by weight:

[0064]40 parts of dimethyl silicone oil, 0.25 parts of sorbitan monolaurate, 0.30 parts of Tween 20, 0.07 parts of sodium lauryl sulfonate, 2.0 parts of compound modification components, and 80 parts of water.

[0065]The compound modified additive includes the following components by weight:

[0066]0.8 part of tributyl phosphate, 0.5 part of ethyl paraben, 0.2 part of pH adjuster, 0.4 part of thickener, 0.3 part of metal ion shielding agent;

[0067]Wherein, the pH regulator is a sodium hydroxide solution with a mass concentration of 10%, the thickener is a carboxymethyl cellulose solution with a mass concentration of 5%, and the metal ion shielding agent is EDTA.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com