A method for synthesizing high-purity hexagonal columnar silica nanoporous material

A silicon dioxide and nanoporous technology, applied in the field of material science research, can solve the problem that the nanopore structure is very different, and achieve the effect of uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

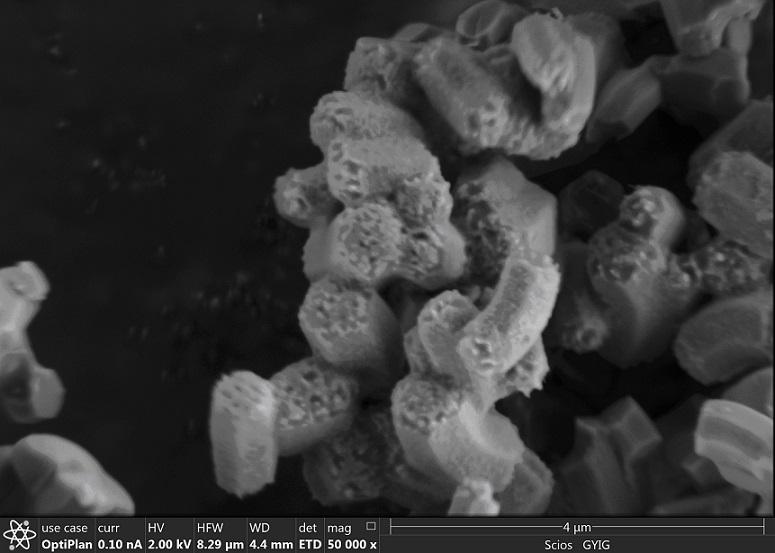

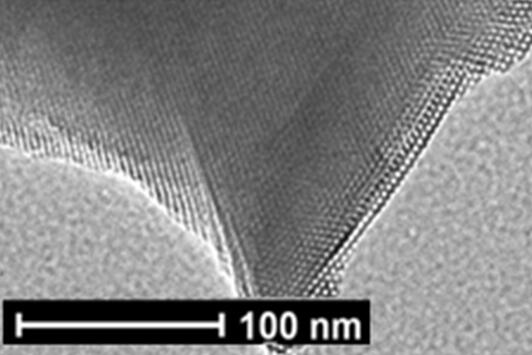

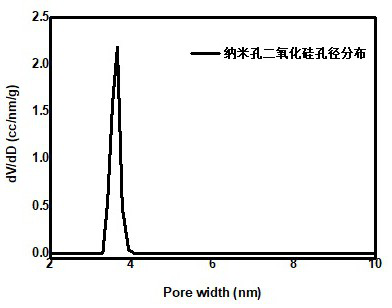

[0018] refer to Figure 1-3 , a method for synthesizing high-purity hexagonal columnar silicon dioxide nanoporous material, comprising the following steps:

[0019] Step 1: Tetradecyltrimethylammonium bromide C with 99% purity of the template 14 h 29 (CH 3 ) 3 N + Br - Dissolve in deionized water at 27°C, stir until the solution is clear, add ammonia solution with a mass fraction of 25%-28%, continue stirring for 10 minutes, add 99% pure tetraethyl orthosilicate Si (OCOCH 3 ) 4 , stirring while adding, the molar ratio of tetraethyl orthosilicate to template agent is 1:0.152, let the mixture react at 27°C for 1h, and the pH value of the reaction mixture is controlled at 10.6-10.8; Tetradecyl trimethyl The selection of the ammonium bromide template is helpful for the formation of hexagonal columns, and the selection of the pH range is helpful for the formation of ordered nanopores.

[0020] Step 2: Put the reacted solution in step 1 into a hydrothermal reaction kettle, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com