Light-cured hydroxyapatite ceramic slurry and preparation method and application thereof

A technology of hydroxyapatite and ceramic slurry, which is applied in the field of functional ceramics, can solve the problems of restricting the application of hydroxyapatite and less photocuring forming technology, and achieve the effects of low cost, stable mechanical properties and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3 and comparative example 1-3

[0036] A photocurable hydroxyapatite slurry comprises the following components in parts by weight: modified hydroxyapatite powder, diluent, and photoinitiator.

[0037] The modified hydroxyapatite powder is prepared by mixing hydroxyapatite powder, a surface modifier and a dispersant.

[0038] In the examples and comparative examples, the amount of each component is based on the hydroxyapatite powder and calculated according to the mass ratio.

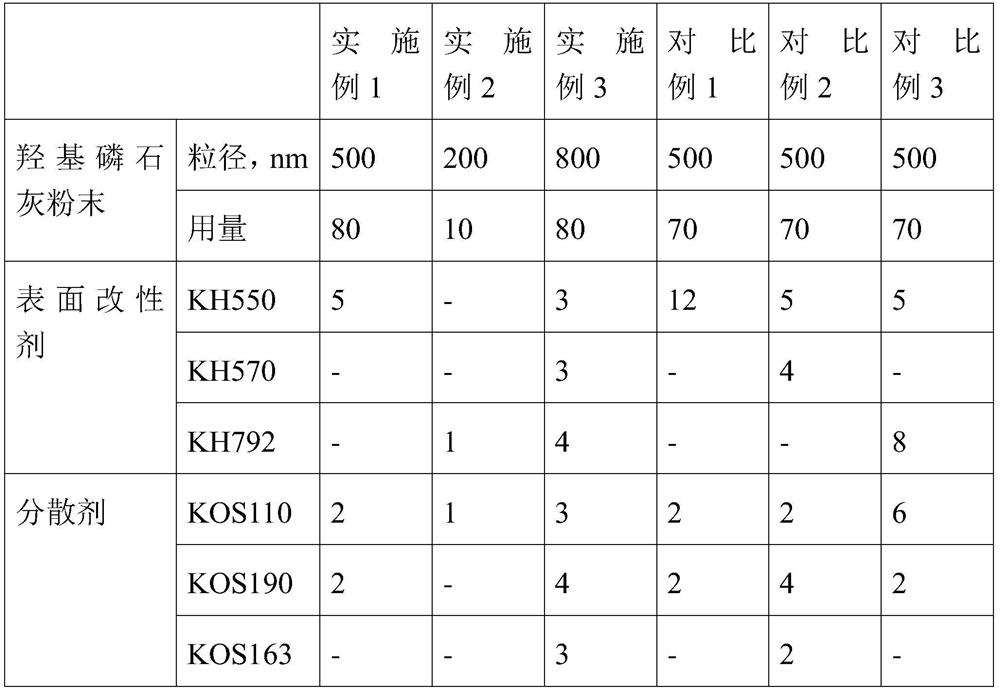

[0039] The formula of modified hydroxyapatite powder is as shown in table 1:

[0040] Table 1

[0041]

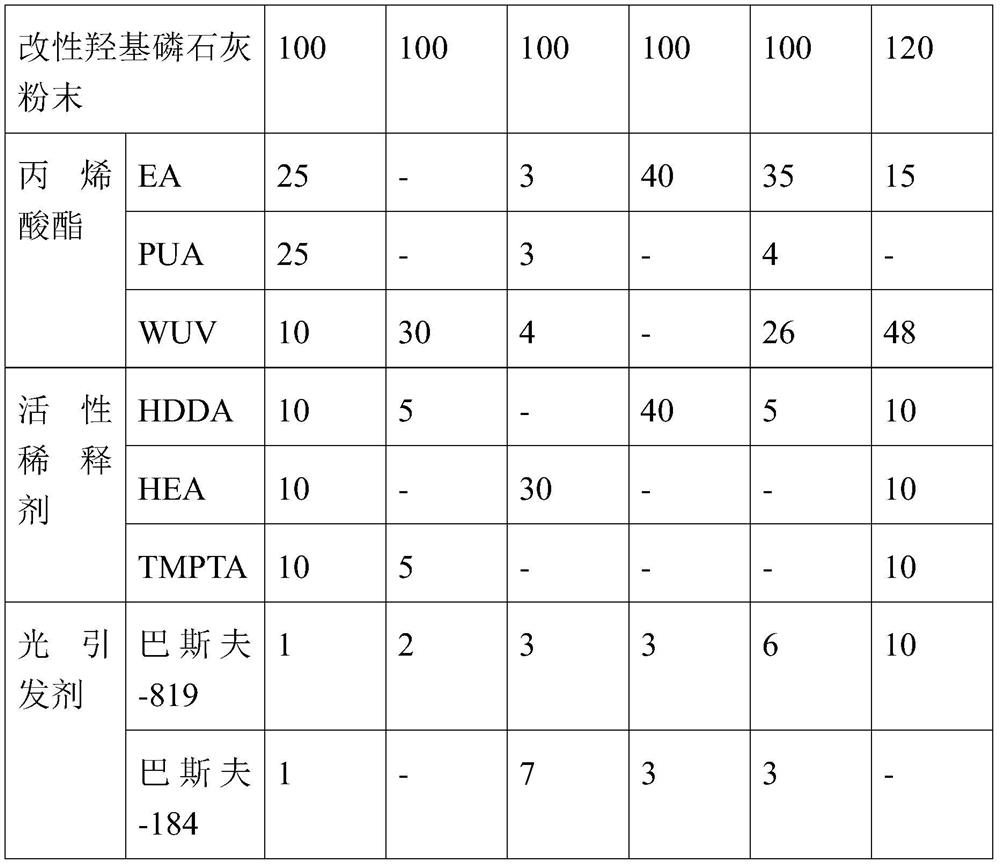

[0042] The formula of light-cured hydroxyapatite ceramic slurry is shown in Table 2:

[0043] Table 2

[0044]

[0045]

[0046] The preparation method of light-cured hydroxyapatite slurry comprises the following steps:

[0047] (1) drying after mixing the hydroxyapatite powder, a dispersant and a surface modifier, to obtain a modified hydroxyapatite powder;

[0048] (2) mixing acrylate, reactive diluent and photoinitiat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com