Preparation method of 5-ethyl-1, 3-dioxane-5-methanol

A technology of dioxane and ethyl, which is applied in the field of preparation of 5-ethyl-1,3-dioxane-5-methanol, can solve the problems of high reaction temperature, low conversion rate and low content, and achieve non-toxic The effect of solvent residue, low production cost and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

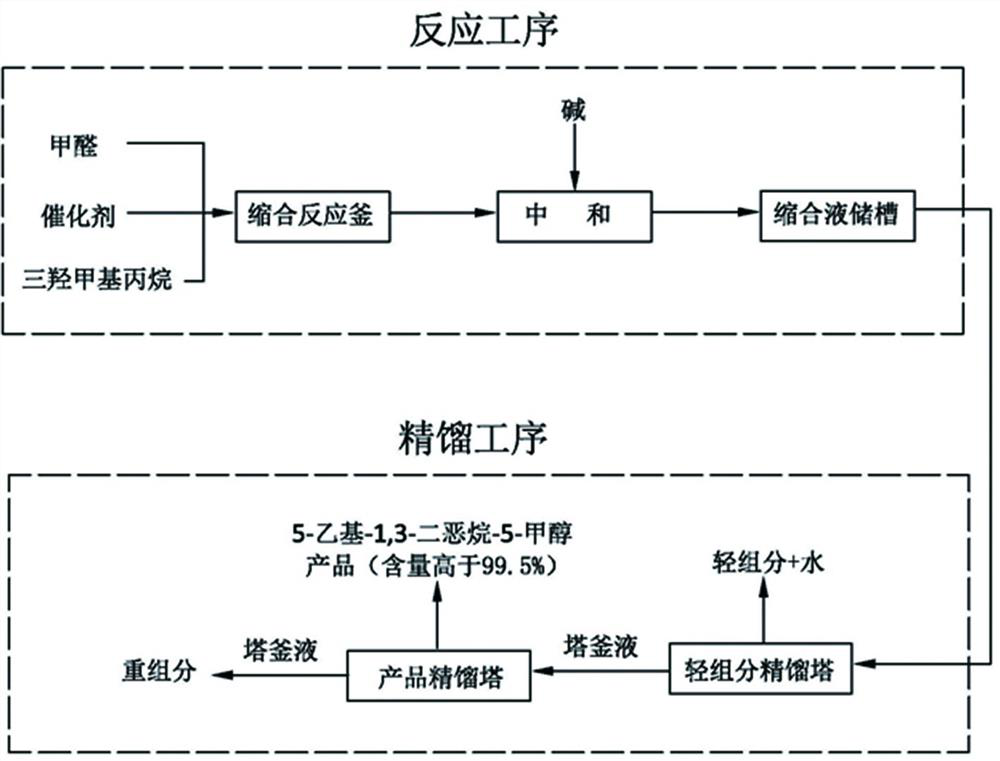

Method used

Image

Examples

Embodiment 1

[0017] Weigh 10000Kg of trimethylolpropane with a mass percentage of 99%, weigh 2332Kg of paraformaldehyde with a mass percentage of 95%, the molar ratio of trimethylolpropane to formaldehyde is 1:1.0, and weigh a mass percentage of 98% 63Kg of methanesulfonic acid is safely dropped into the condensation reactor. The reactor was replaced with nitrogen and the pressure was maintained, and the reaction was carried out at a temperature of 116° C. for 11 hours. After the reaction was completed, 32% NaOH solution was added to adjust the pH to neutral. The reaction solution was detected by gas chromatography equipped with an FID detector and the results were: CTF: 87%, TMP: 6%, other components: 7%.

[0018] The above reaction liquid is sent to the light component rectification tower for separation, the reaction liquid is fed from the middle of the light component rectification tower, the pressure is 0.05KPa absolute pressure, the reflux ratio is 0.1, and the formaldehyde and water...

Embodiment 2

[0020] Weigh 10000Kg of trimethylolpropane with a mass percentage of 99%, 5390Kg of a formaldehyde solution with a mass percentage of 37%, the molar ratio of trimethylolpropane to formaldehyde is 1:0.9, and weigh a mass percentage of 98% 157Kg of p-toluenesulfonic acid was safely put into the condensation reactor. The reactor was replaced with nitrogen and the pressure was maintained, and the reaction was carried out at a temperature of 116° C. for 10 hours. After the reaction was completed, 32% NaOH solution was added to adjust the pH to neutral. The reaction solution was detected by gas chromatography equipped with an FID detector, and the results were: CTF: 85%, TMP: 11%, and other components: 4%.

[0021] The above-mentioned reaction solution is sent to the light component rectification tower for separation, the reaction solution is fed from the middle of the light component rectification tower, the pressure is 50KPa absolute pressure, the reflux ratio is 15, and the ligh...

Embodiment 3

[0023] Weigh 10000Kg of trimethylolpropane with a mass percentage of 99%, 7186Kg of a formaldehyde solution with a mass percentage of 37%, the molar ratio of trimethylolpropane to formaldehyde is 1:1.2, and weigh a mass percentage of 98% Sulfuric acid 175Kg is safely put into the condensation reactor. The reactor was replaced with nitrogen and the pressure was maintained, and the reaction was carried out at a temperature of 118° C. for 9 hours. After the reaction was completed, 32% NaOH solution was added to adjust the pH to neutral. The reaction solution was detected by gas chromatography equipped with an FID detector, and the results were: CTF: 81%, TMP: 3%, and other components: 16%.

[0024] The above reaction liquid is sent to the light component rectification tower for separation, the reaction liquid is fed from the middle of the light component rectification tower, the pressure is 15KPa absolute pressure, the reflux ratio is 8, and the light product containing formalde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com