Solid catalyst component for olefin polymerization, preparation method of solid catalyst component, olefin polymerization catalyst and olefin polymerization method

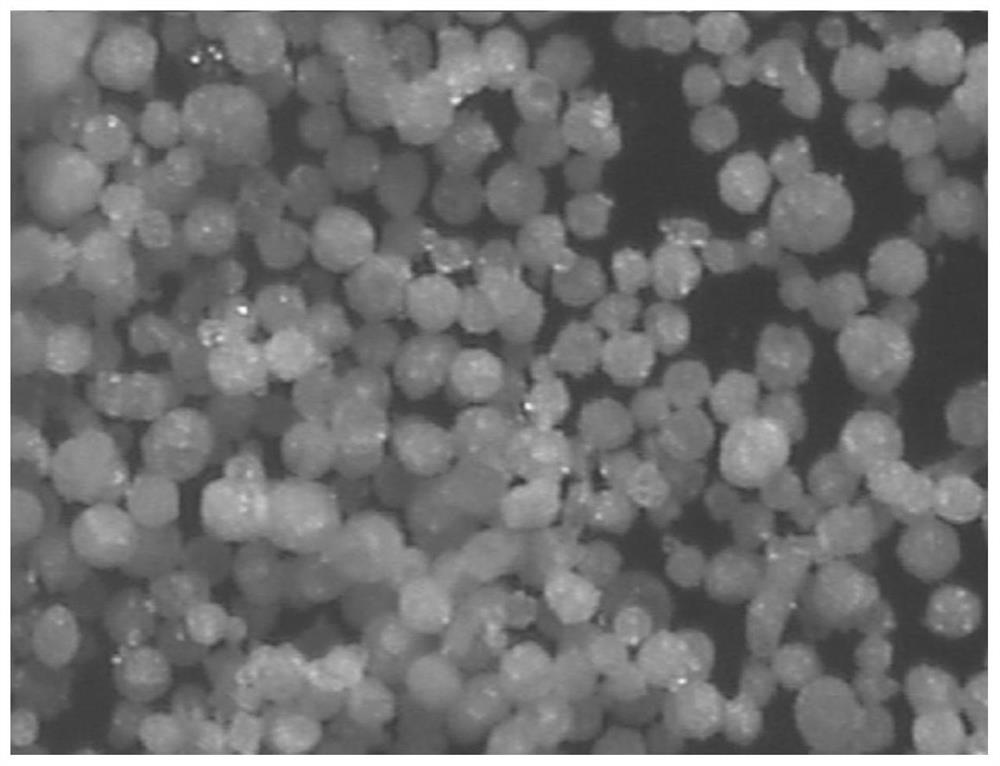

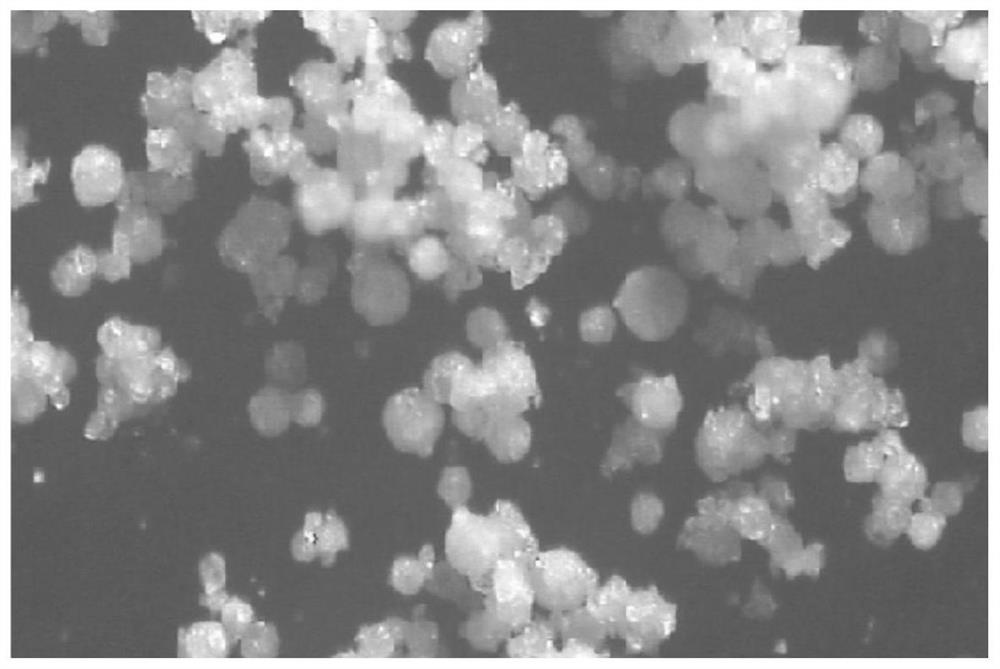

A solid catalyst and olefin polymerization technology, which is applied in the field of solid catalyst components for olefin polymerization and its preparation, olefin polymerization catalysts and olefin polymerization, can solve the problems of high polymer fine powder content, broken catalyst, and low commercial value, and achieve Less broken particles and good regularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] According to a first aspect of the present invention, the present invention provides a method for preparing a solid catalyst component for olefin polymerization, the preparation method comprising the following steps:

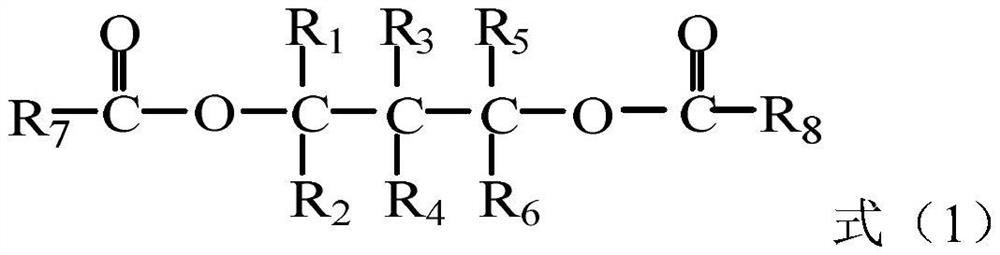

[0028] (1) In the presence of an inert solvent, the catalyst component A, aluminum alkyl and an external electron donor are subjected to a contact reaction; the catalyst component A contains titanium, magnesium, chlorine and an internal electron donor; the internal electron donor Body comprises glycol esters shown in formula (1):

[0029]

[0030] In formula (1), R 1 -R 6 each independently selected from hydrogen, C 1 -C 10 straight-chain or branched-chain alkyl, C 3 -C 10 Cycloalkyl, C 6 -C 10 Aryl, C 7 -C 10 Alkaryl or C 7 -C 10 an aralkyl group; and R 1 -R 6 Two or more groups in are optionally bonded to each other to form one or several fused ring structures;

[0031] R 7 and R 8 each independently selected from C 1 -C 10 straight...

Embodiment 1

[0103] (1) Preparation of Catalyst Component A

[0104] Add 1.2L of titanium tetrachloride to a stirred 3L glass reaction bottle and cool down to -20°C, then add 100g of magnesium chloride alcoholate spherical carrier [Mg(C 2 h 5 Oh) 2.6 ] (average particle size D50=45μm, the same below), reacted at -20°C for 0.5 hours, then slowly raised the temperature to 120°C, added 15g of 2,4-pentanediol dibenzoate during the heating process, and then heated at 120°C React at low temperature for 0.5 hours, filter off the liquid, add 1L of titanium tetrachloride, and maintain at 120°C for 2 hours, then filter off the liquid to obtain a solid product, wash the obtained solid product with hexane for 5 times, and finally dry it in vacuum to obtain Catalyst component A (average particle size D50 = 40 μm), denoted as A1.

[0105] (2) Preparation of solid catalyst component

[0106] In a 5L autoclave, add 1.1L hexane, 15mmol triethylaluminum, 0.3mmol cyclohexylmethyldimethoxysilane and 10.9g...

Embodiment 2

[0110] (1) Preparation of Catalyst Component A

[0111] Add 1.2L of titanium tetrachloride to a stirred 3L glass reaction bottle and cool down to -20°C, then add 100g of magnesium chloride alcoholate spherical carrier [Mg(C 2 h 5 Oh) 2.6 ], react at -20°C for 0.5 hours, then slowly raise the temperature to 120°C, add 15g of 2,4-pentanediol dibenzoate and 15g of 2-isopropyl-2-isoamyl-1 , 3-dimethoxypropane, then reacted at 120°C for 0.5 hours, filtered off the liquid, added 1L of titanium tetrachloride, maintained at 120°C for 1 hour, filtered off the liquid to obtain a solid product, and obtained the solid The product was washed 5 times with hexane, and finally dried under vacuum at 45° C. to obtain catalyst component A (average particle size D50 = 41 μm), denoted as A2.

[0112] (2) Preparation of solid catalyst component

[0113] In a 5L autoclave, add 1.1L hexane, 15mmol triethylaluminum, 0.3mmol cyclohexylmethyldimethoxysilane and 10.8g catalyst component A2, react at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com