Cleaning solution for removing surface residues after CMP of multi-layer copper interconnection barrier layer

A technology of barrier layer and cleaning liquid, applied in the field of microelectronics, can solve the problems affecting the yield, performance and reliability of devices, adverse effects on equipment performance, etc., and achieve the effects of good stability, simple preparation method and simple composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Take 1% of FA / O chelating agent, 2% of dodecyl dimethyl amine oxide (OA), 4% of FA / O surfactant, 6% of dodecylbenzenesulfonic acid (LABSA), silicone defoaming Agent (AFE-1410) 1%. The specific preparation method is as follows: add FA / O chelating agent, OA, FA / O surfactant, LABSA, and antifoaming agent to an appropriate amount of deionized water in sequence, stir evenly through step-by-step mixing, and finally fill up with deionized water to 1000g, continue to stir evenly, add a pH regulator (nitric acid or potassium hydroxide), and adjust the pH value to 7.5 to obtain the cleaning solution S3.

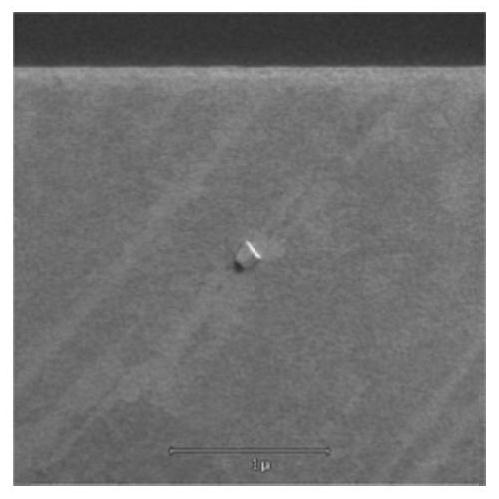

[0044] Residual defect test experiment: Clean the polished copper pattern sheet with cleaning solution S4, and then detect surface residues with a scanning electron microscope (SEM). The number of residual defects is shown in Table 1, and the map of residual defects is shown in Figure 11As shown, the SEM image is shown in Figure 12 shown.

Embodiment 2

[0046] Take 1% of FA / O chelating agent, 2% of dodecyl dimethyl amine oxide (OA), 4% of FA / O surfactant, 6% of dodecylbenzenesulfonic acid (LABSA), fatty alcohol polyoxygen Vinyl ether (JFC) 3%, silicone defoamer (AFE-1410) 1%. The specific preparation method is as follows: add FA / O chelating agent, OA, FA / O surfactant, LABSA, and antifoaming agent to an appropriate amount of deionized water in sequence, stir evenly through step-by-step mixing, and finally fill up with deionized water to 1000g, continue to stir evenly, add a pH regulator (nitric acid or potassium hydroxide), and adjust the pH value to 7.5 to obtain the cleaning solution S4.

[0047] Residual defect test experiment: Clean the polished copper pattern sheet with cleaning solution S4, and then detect surface residues with a scanning electron microscope (SEM). The number of residual defects is shown in Table 1, and the map of residual defects is shown in Figure 15 As shown, the SEM image is shown in Figure 16 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com