High-power chip heat dissipation system and method with built-in intestinal villus imitating micro-needle ring

A chip heat dissipation and high-power technology, applied in cooling/ventilation/heating transformation, electrical components, electrical equipment structural components, etc., can solve the problem that chip heat sinks cannot meet chip heat dissipation requirements, etc. Heat dissipation efficiency, the effect of improving the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

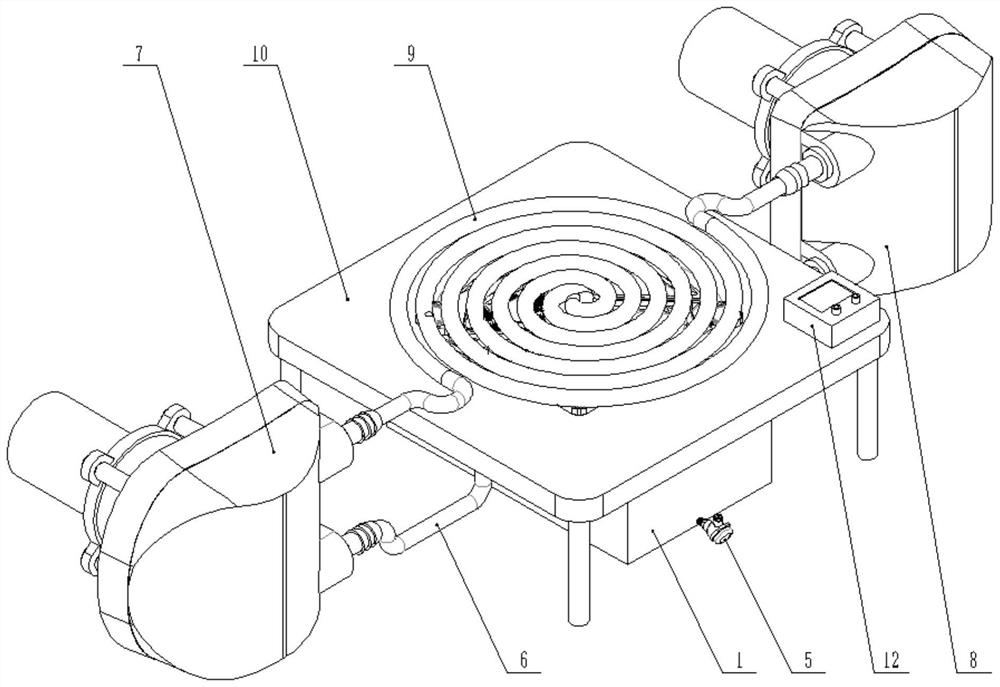

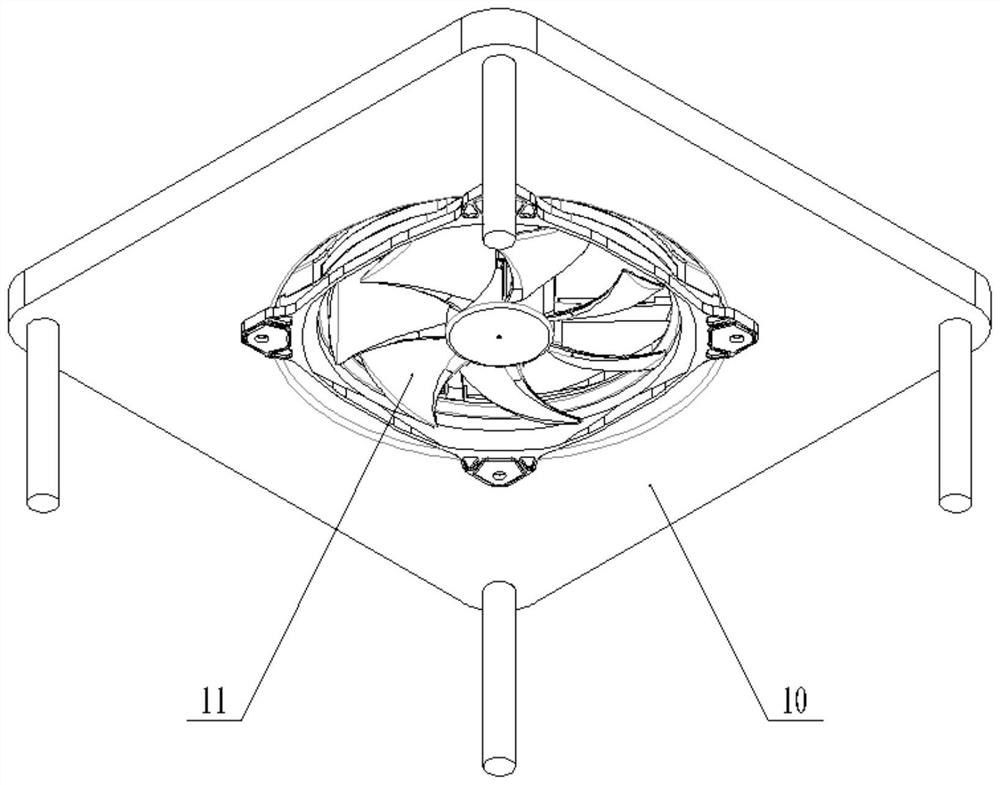

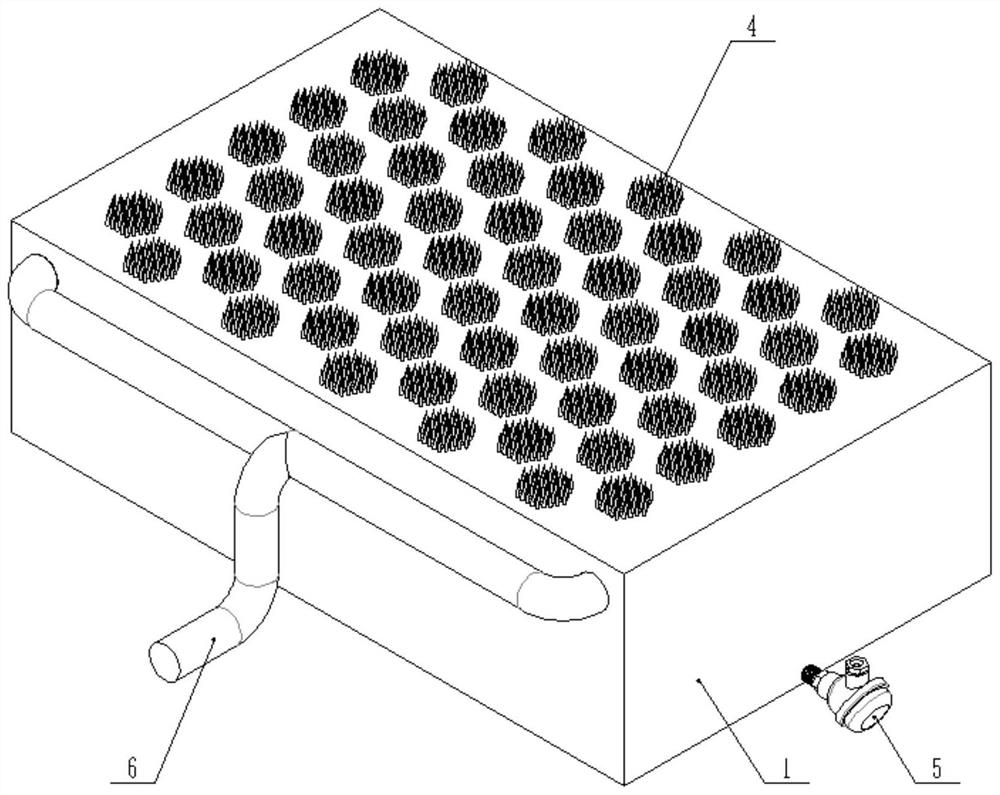

[0030] like figure 1 , figure 2 , image 3 and Figure 4As shown, the built-in high-power chip heat dissipation system imitating small intestinal villi microneedle ring includes fan bracket 10, fan 11, heat absorption box 1, three-layer coiled liquid channel 2, double vortex linear condenser tube 9, and inlet peristaltic pump 7 and an outlet peristaltic pump 8; the fan support 10 includes a support plate and a column; the support plate is fixed on four columns and placed above the heat-absorbing box 1; a fan 11 is fixed at the central hole of the support plate, and a control panel is provided on the support plate plate 12; the air outlet at the top of the fan 11 is bonded to the double vortex linear condensing pipe 9; the heat-absorbing box 1 is fixed with a three-layer coiled liquid channel 2, and the three-layer coiled liquid channel 2 is embedded with a number of imi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Bottom radius | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com