Hyaluronic acid quaternary ammonium salt compound

A technology of hyaluronic acid and complex, applied in cosmetics, cosmetic preparations, cosmetic preparations, etc., can solve the problems of inability to obtain moisturizing effect and smoothness, and achieve the purpose of repairing keratin damage, increasing suppleness, and increasing skin moisture. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

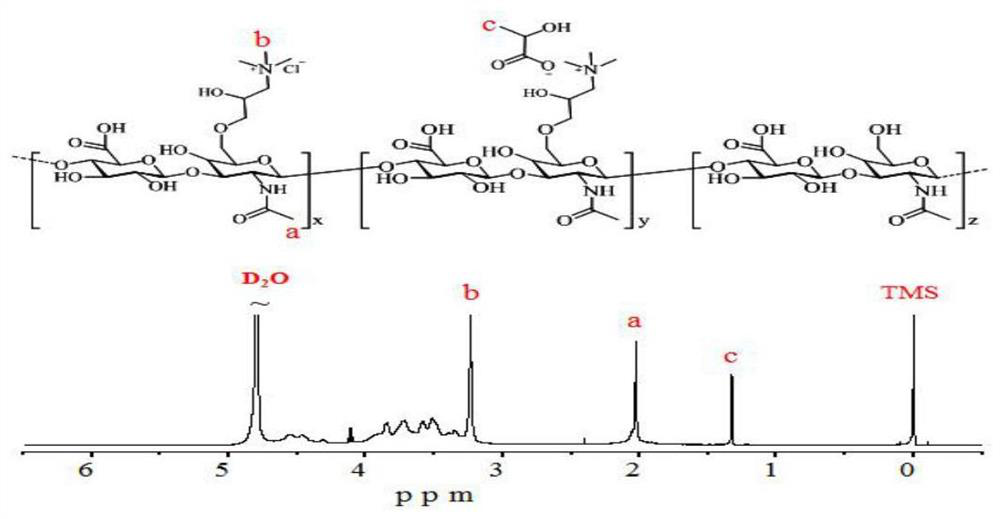

[0037] The preparation of embodiment 1 hyaluronic acid quaternary ammonium salt complex

[0038] Take 10g of sodium hyaluronate (average molecular weight 1680kDa) and 5.0g of 3-chloro-2-hydroxypropyltrimethylammonium chloride and mix, add 100ml of 0.5% (g / ml) sodium hydroxide hydroalcoholic mixed solution, which contains Ethanol 50% (g / ml), stirred for 1 hour at 50±2°C, add 10% (g / ml) lactic acid-sodium lactate aqueous solution 300ml, dissolve and dilute the reaction product, filter, collect the filtrate, add 95% ethanol 1500ml, precipitate, remove the supernatant, filter and collect the precipitate, then add 500ml of 95% ethanol to wash the precipitate twice, place it in a constant temperature drying oven at 40°C for 6 hours under reduced pressure to obtain hyaluronic acid with a substitution degree of 0.41 and a lactic acid binding rate of 45% Quaternary ammonium salt complex.

Embodiment 2

[0039] The preparation of embodiment 2 hyaluronic acid quaternary ammonium salt complex

[0040] Mix 10g of sodium hyaluronate (average molecular weight 840kDa) with 10g of 2,3-epoxypropyltrimethylammonium chloride, add 100ml of 1% (g / ml) sodium hydroxide hydroalcoholic mixed solution, which contains ethanol 80 % (g / ml), at 40 ± 2 ℃ of thermal insulation and stirring reaction for 2 hours, add 12% (g / ml) lactic acid-sodium lactate aqueous solution 400ml, dissolve and dilute the reaction product, filter, collect the filtrate, add 95% ethanol 2000ml, Precipitate, remove the supernatant, collect the precipitate by filtration, add 500 ml of 95% ethanol to wash the precipitate twice, and place it in a constant temperature drying oven at 40°C for drying under reduced pressure for 6 hours to obtain quaternary ammonium hyaluronate with a degree of substitution of 0.76 and a lactic acid binding rate of 85%. salt complex.

Embodiment 3

[0041] The preparation of embodiment 3 hyaluronic acid quaternary ammonium salt complex

[0042] Mix 10g of sodium hyaluronate (average molecular weight 530kDa) with 6g of 2,3-epoxypropyltrimethylammonium chloride, add 100ml of 1.5% (g / ml) aqueous sodium hydroxide solution, and keep stirring at 30±2°C React for 4 hours, add 300ml of 15% (g / ml) lactic acid-sodium lactate aqueous solution, dissolve and dilute the reaction product, filter, collect the filtrate, add 1600ml of acetone, precipitate, remove the supernatant, filter and collect the precipitate, then add absolute ethanol 500ml of the precipitate was washed twice, placed in a constant temperature drying oven at 40°C for 6 hours under reduced pressure to obtain a hyaluronic acid quaternary ammonium salt complex with a substitution degree of 1.48 and a lactic acid binding rate of 67%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com