Hydrolysis device for preparing p-toluenesulfonyl chloride and processing technology

A technology for preparing toluenesulfonyl chloride and p-toluenesulfonyl chloride, which is applied in the field of hydrolysis devices for preparing p-toluenesulfonyl chloride, can solve the problems of slow temperature drop in reaction space, prolonged temperature time, reduced hydrolysis reaction accuracy, and the like, so as to improve the dissolution rate. Depth, improve hydrolysis effect, high degree of automation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

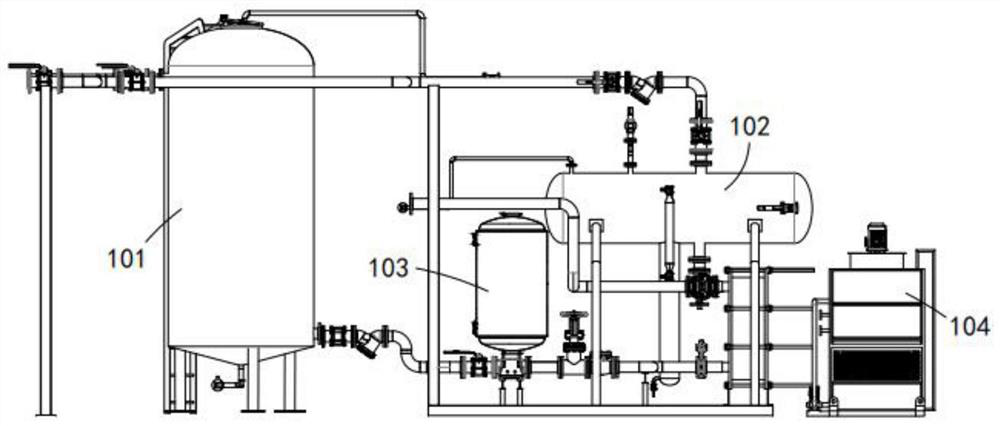

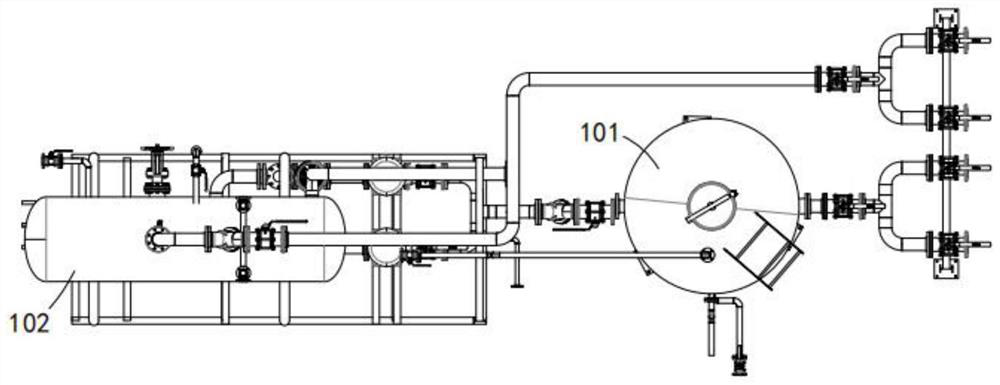

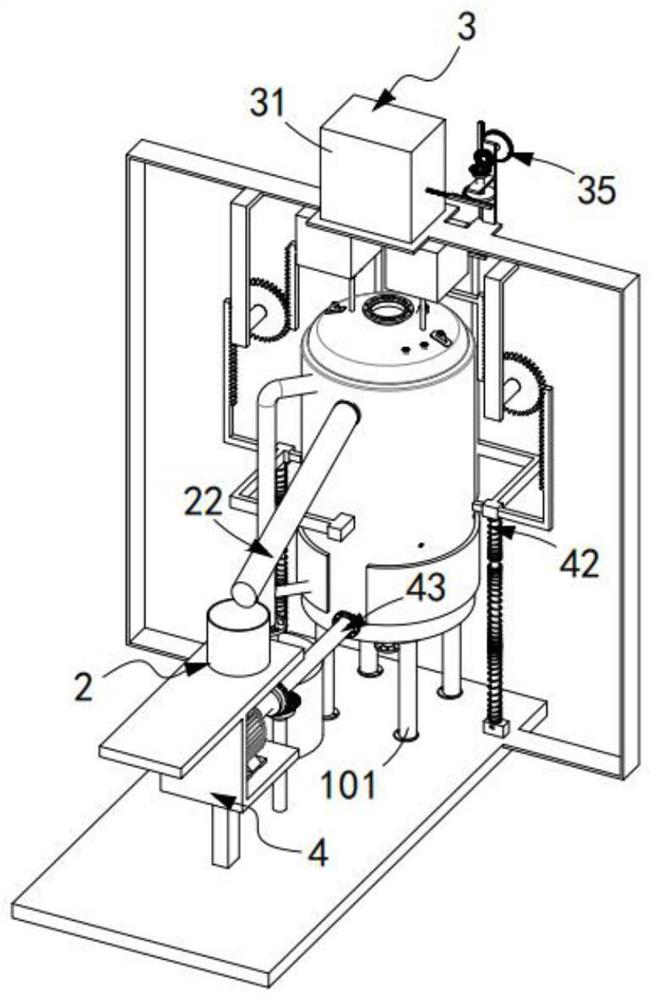

[0060] Such as Figure 1 to Figure 3 As shown, a kind of hydrolysis device for the preparation of p-toluenesulfonyl chloride includes a hydrolysis reactor 101, and also includes a cleaning mechanism 2, a uniform dripping mechanism 3, and a stirring mechanism 4 arranged in the hydrolysis reactor 101 and arranged in a vertical direction. And the gasoline transmission mechanism 5 arranged outside the hydrolysis reactor 101 and communicated with the hydrolysis reactor 101;

[0061] The uniform dripping mechanism 3 includes a water container 31 arranged outside the hydrolysis reaction kettle 101, a first connection pipe 32 that is connected to the water container 31 at one end and sealed with the other end in the hydrolysis reaction kettle 101, The uniform drip assembly 33 arranged in the hydrolysis reactor 101 and communicated with the first connecting pipe 32, driving the uniform drip assembly 33 to lift in the vertical direction and located outside the hydrolysis reactor 101 Me...

Embodiment 2

[0095] Such as Figure 20 Shown, a kind of p-toluenesulfonyl chloride processing technology comprises:

[0096] Step 1, the production of tosyl chloride, artificially select a certain amount of chlorosulfonic acid, and add it to the 3000L reactor 102, and in the environment of 30-50°C, add some amount of toluene dropwise under negative pressure to 3000L for reaction In the kettle 102, the dropwise addition is completed, and after the temperature rises, the insulation is placed;

[0097] Step 2, hydrolysis reaction, the mixture in step 1 hydrolysis reaction kettle 101 is added in the hydrolysis reaction kettle 101, start drive mechanism 34, make dripping water under the condition of negative pressure;

[0098] Step 3, adjusting the reaction temperature, synchronously with the step 2, the driving mechanism 34 respectively drives the first pressure limiting component 333 and the third pressure limiting component 334 to move downwards to complete the dripping work and simultaneou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com