Coating machine for compound fertilizer production

A coating machine and compound fertilizer technology, applied in application, fertilization equipment, fertilizer mixture, etc., can solve the problems of inconvenient use and inconvenient cleaning of the coating machine, and achieve convenient maintenance, good coating effect and easy coating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

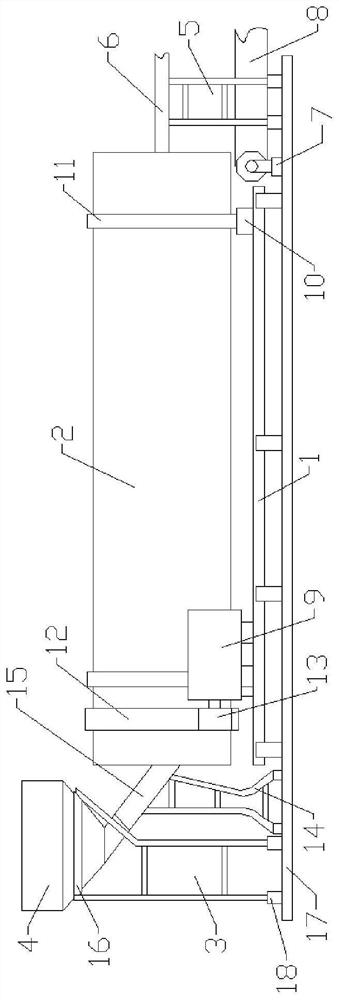

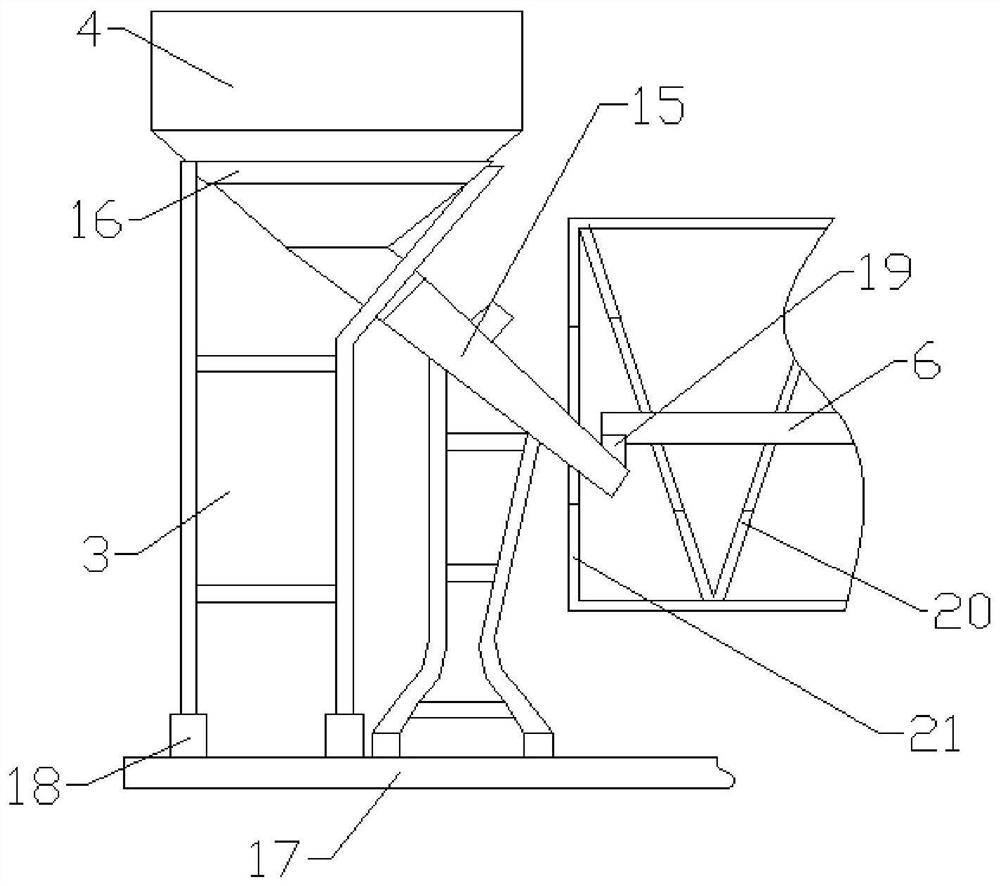

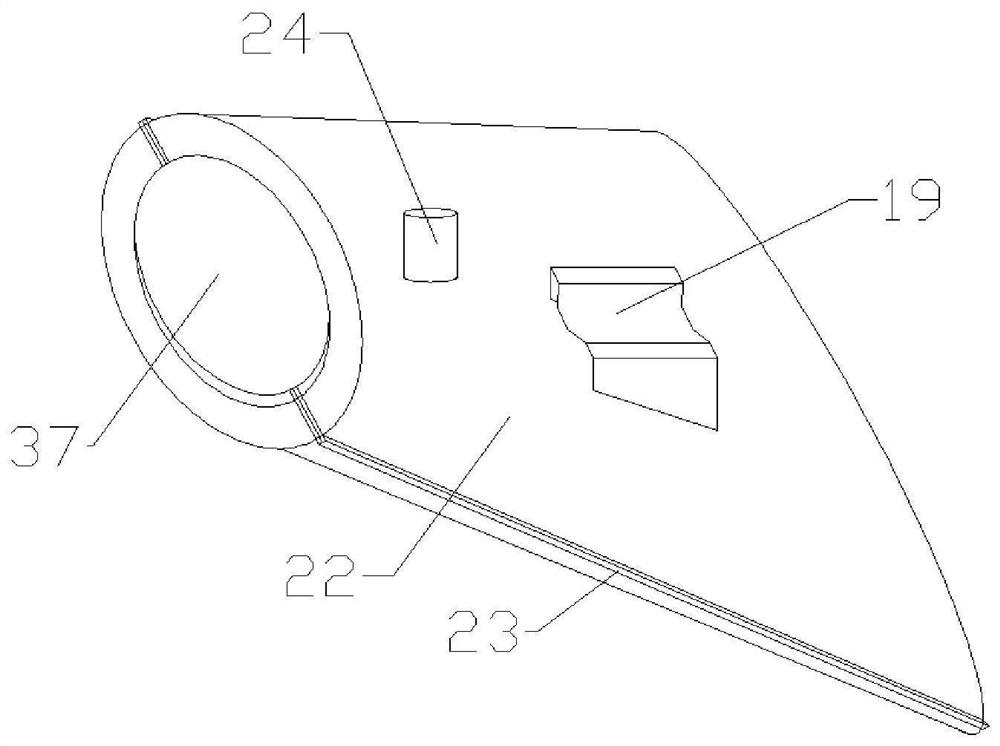

[0029] like Figure 1-12 As shown, a coating machine for compound fertilizer production includes a mobile frame 1, the mobile frame 1 is welded and formed by a rectangular tube, and has high structural strength and light weight, and a coating roller 2 is installed on the mobile frame 1. The inner wall of the film drum is welded with a helical blade 20, and a driving motor 9 for driving the rotation of the film drum is fixed on the first moving frame. The frame consists of two parallel long and side-standing steel plates. The middle of the steel plates is machined with an arc-shaped opening to prevent interference with the coating roller. An end plate is fixed between the ends of the two steel plates, and both ends of the support frame are installed. There are support rollers 36, and the central angle formed by the two support rollers on the same support frame with respect to the axis of the coating roller is 60-70°, which can prevent the coating roller from detaching. The coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com