Nitroguanidine production process

A production process and technology for nitroguanidine, applied in the field of nitroguanidine production technology, can solve the problems of environmental pollution, waste of resources, poor mechanical properties and the like, and achieve the effects of simple process and low requirements for process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

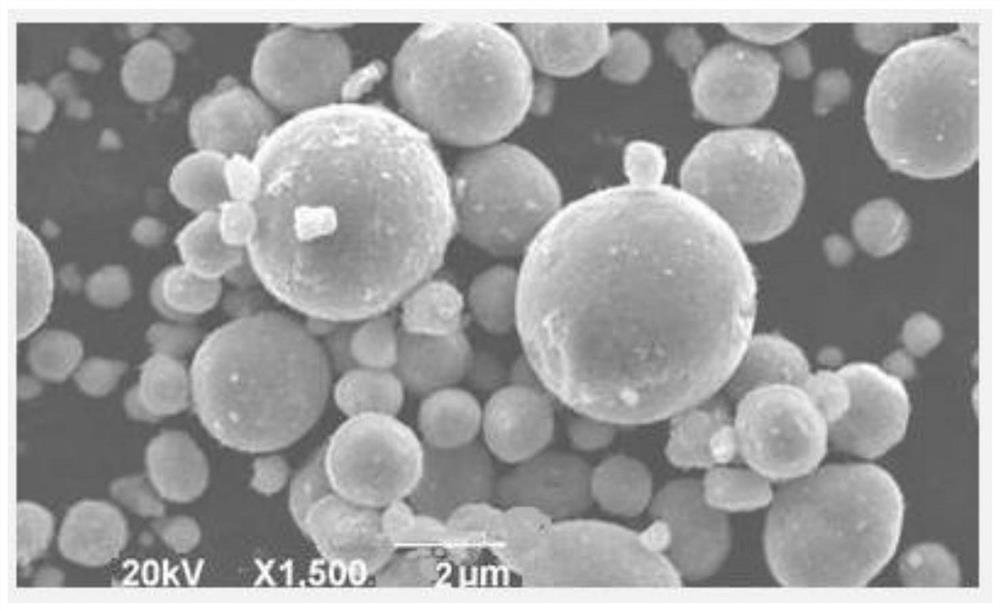

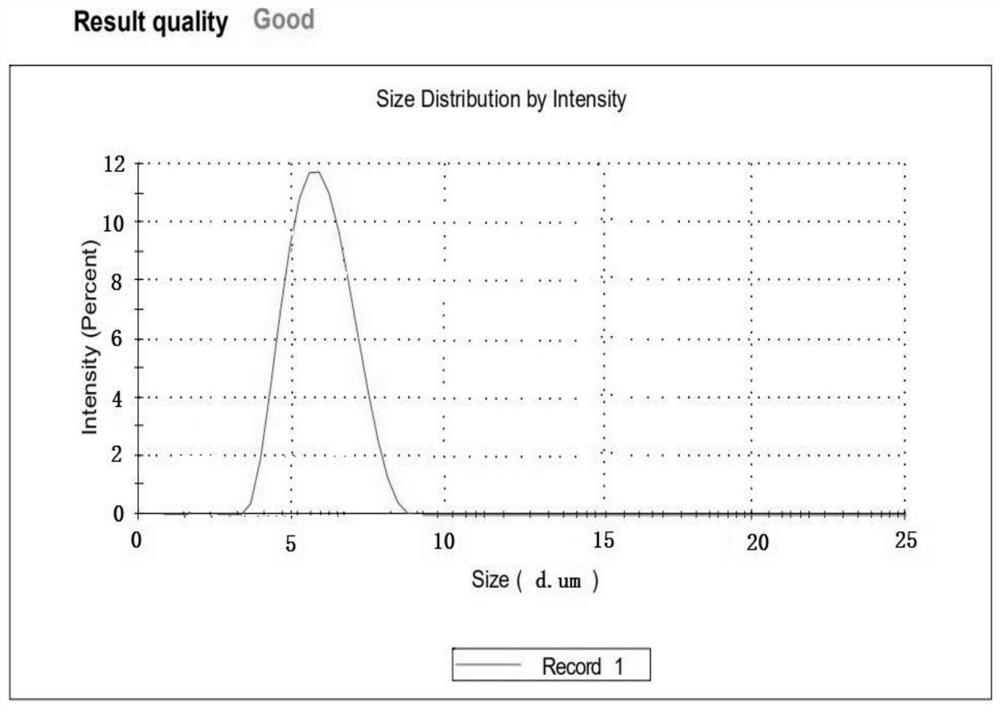

[0043] (1) Nitroguanidine synthesis

[0044] Pump concentrated nitric acid from the nitric acid storage tank into the mixing kettle through the metering pump, start stirring, and open the refrigerant inlet and outlet valves of the jacket of the mixing kettle at the same time; wait for the concentrated nitric acid in the kettle to cool down to 2°C, start the solid feeder and measure through the electronic scale , slowly add the guanidine nitrate in the hopper into the mixing tank, and control the temperature of the material in the mixing tank to 5°C; use a metering pump to pass the mixed solution into the microtube impingement flow reactor, react at 45°C for 10 minutes, and cool down through the microtube to 5°C for crystallization;

[0045] (2) Dilute crystallization and centrifugation

[0046] The crystallization tank is prepared to measure 45% dilute nitric acid in advance, and the reaction solution and a certain volume of washing liquid are slowly added to the crystallizat...

Embodiment 2

[0057] (1) Nitroguanidine synthesis

[0058] Pump concentrated nitric acid from the nitric acid storage tank into the mixing kettle through the metering pump, start stirring, and open the refrigerant inlet and outlet valves of the jacket of the mixing kettle at the same time; wait for the concentrated nitric acid in the kettle to cool down to 1°C, start the solid feeder and measure through the electronic scale , slowly add the guanidine nitrate in the hopper into the mixing tank, and control the temperature of the material in the mixing tank at 7°C; use a metering pump to pass the mixed solution into the microtube impingement flow reactor, react at 47°C for 15 minutes, and cool down through the microtube to 7°C for crystallization;

[0059] (2) Dilute crystallization and centrifugation

[0060] The crystallization tank is prepared to measure 50% dilute nitric acid in advance, and the reaction solution and a certain volume of washing liquid are slowly added to the crystallizat...

Embodiment 3

[0071] (1) Nitroguanidine synthesis

[0072] Pump concentrated nitric acid from the nitric acid storage tank into the mixing kettle through the metering pump, start stirring, and open the refrigerant inlet and outlet valves of the jacket of the mixing kettle at the same time; wait for the concentrated nitric acid in the kettle to cool down to 0°C, start the solid feeder and measure through the electronic scale , slowly add guanidine nitrate in the hopper into the mixing tank, and control the temperature of the material in the mixing tank at 3°C; use a metering pump to pass the mixed solution into the microtube impingement flow reactor, react at 43°C for 20min, and cool down to 3°C for crystallization;

[0073] (2) Dilute crystallization and centrifugation

[0074] The crystallization tank is prepared to measure 55% dilute nitric acid in advance, slowly add the mixed material of the reactor and a certain volume of washing liquid into the crystallization tank in sequence, and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com