Polyamideimide resin and single-sided conductive composite film prepared from same

A technology of polyamide-imide resin and polyamide-imide, applied in electrical components, magnetic field/electric field shielding, coating, etc., can solve the problem of difficult to meet the electromagnetic shielding requirements of optocoupler systems, low elongation at break, Low tensile strength and other problems, to achieve good electromagnetic shielding effect, adjustable strength and toughness, good light transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A transparent polyamide-imide resin with repeating units as shown in the following structure:

[0043]

[0044] Wherein 3000

[0045] A kind of preparation method of transparency polyamide-imide resin comprises the following steps:

[0046] (1) The synthesis of diacid monomer (ODPA-ABA), this reaction can be represented by following reaction formula:

[0047]

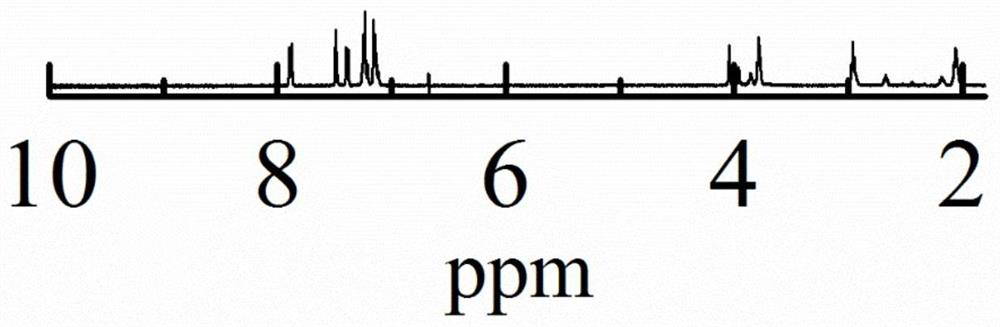

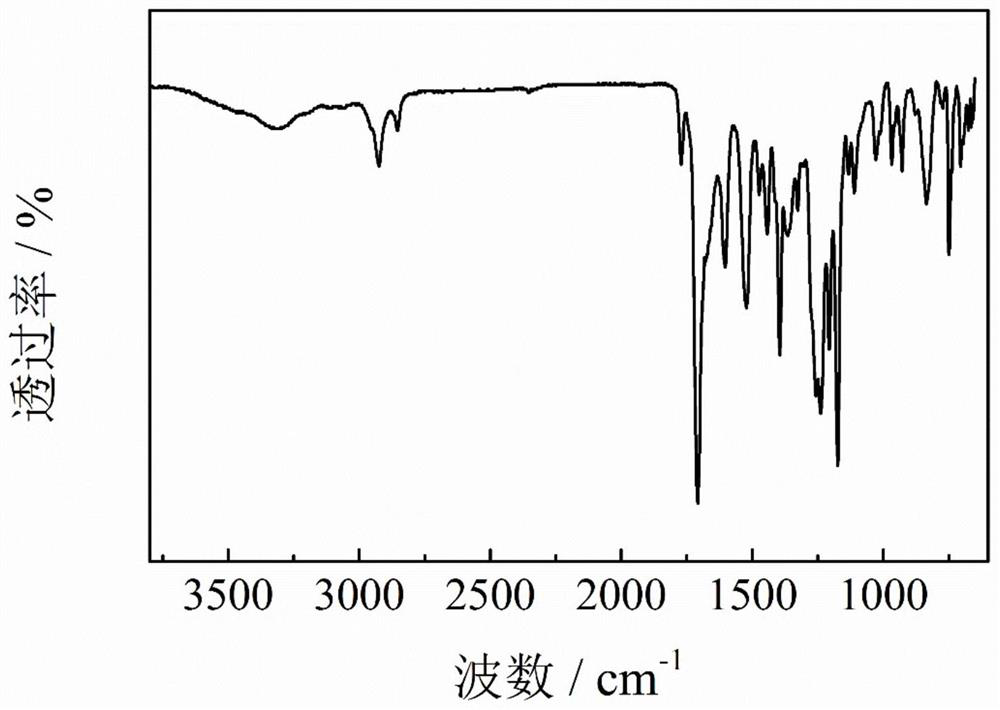

[0048] In a 100ml three-necked flask, add 4,4'-oxydiphthalic anhydride (ODPA) (3.1g, 0.01mol), 4-aminobutyric acid (ABA) (2.34g, 0.02mol) and 20ml acetic acid, in Under a nitrogen atmosphere, the temperature was slowly raised to 110° C., and the reaction was carried out for 11 hours. The reaction solution was cooled to room temperature, filtered to obtain white diacid monomer (ODPA-ABA) (3.49 g, 0.0082 mol), yield: 83%. NMR and infrared data: 1 H NMR (Trifluoroacetic acid-d, 500MHz, δ / ppm): 11.57(broad,COOH),7.90(dd,2H),7.50(d,2H),7.42(dd,2H),3.94(s,4H), 3.83(t,4H), 2.06(t,4H). FTIR (KBr,ν,cm ...

Embodiment 2

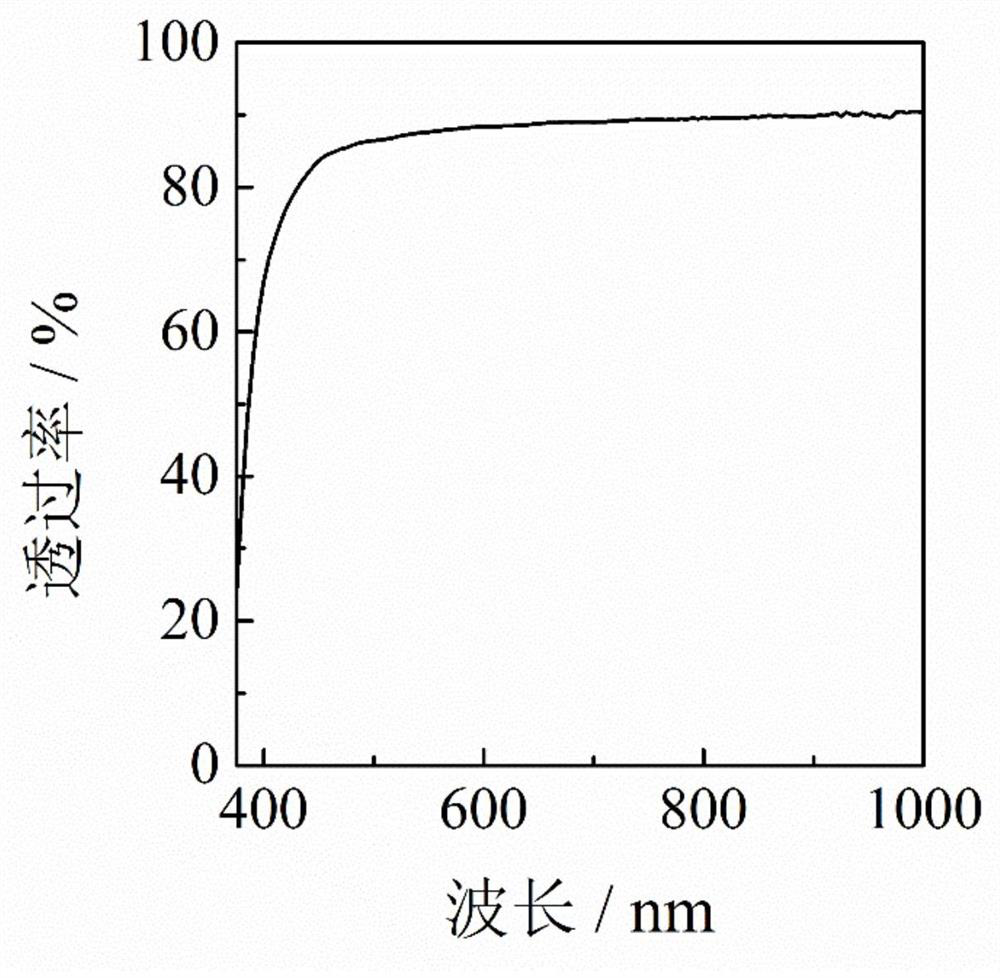

[0072] The difference from Example 1 is that when preparing the base layer, the mass ratio of the transparent polyamide-imide resin to the thermoplastic polyurethane is 1:0. The prepared single-sided conductive composite film has a tensile strength of 120MPa, a Young's modulus of 4700MPa, an elongation at break of 9.2%, and a light transmittance of 80%, exceeding 40dB in the range of 30Mhz-6GHz.

Embodiment 3

[0074] The difference from Example 1 is that when preparing the base layer, the mass ratio of the transparent polyamide-imide resin to the thermoplastic polyurethane is 0:1. The prepared single-sided conductive composite film has a tensile strength of 35MPa, a Young's modulus of 4.1MPa, an elongation at break of 1100%, and a light transmittance of 81%, exceeding 40dB in the range of 30Mhz-6GHz.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com