Bacillus siamensis capable of being used for repairing concrete cracks, microbial inoculum and application

A Bacillus, concrete technology, applied in the field of microorganisms, can solve problems such as expensive, staying, and small cracks that cannot be repaired

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032]Example 1: Screening and identification of strains adapted to the preparation of concrete self-repairing bacteria

[0033]1) Take 1g of soil sample from the ancient canal on the Chaohui campus of Zhejiang University of Technology and add it to a sterilized Erlenmeyer flask with small glass beads and 100mL sterile water, shake at 30℃, 200r / min for 30min, and then stand for 10min. , To remove the bottom sediment to obtain a soil suspension. Place the soil suspension in water at 100°C for heating in a boiling water bath for 3-5 min to obtain a soil sample stock solution.

[0034]Perform a gradient dilution of the original soil sample solution in an ultra-clean bench with a concentration gradient of 10-1, 10-2, 10-3, 10-4, 10-5, 10-6Draw 200μL of the bacterial suspension of each concentration and inoculate it on a plate with a selection medium for urease-producing strains, seal the plate with a parafilm and invert it, place it in a constant temperature incubator at 37°C for 24 hours, an...

Embodiment 2

[0043]Example 2: The effect of different conditions on the urease activity of strain ZJB20040

[0044]1) Thermal stability

[0045]Due to the exothermic heat of the hydration process during concrete pouring, the temperature will rise to above 40°C, so the strain ZJB20040 suspension with a concentration of 10 mg / mL was treated in a water bath at 40, 45, 50, 55, and 60°C for 60 minutes. After cooling, count the stained bacterial suspension with a hemocytometer to calculate the ratio of live cells to dead cells. The survival rate of the strain ZJB20040 below 60°C remained above 93%, indicating that the strain ZJB20040 has better thermal stability.

[0046]2) Alkali stability

[0047]Because the hydration process in concrete pouring will make the pH between 12-13, the strain ZJB20040 with a concentration of 10mg / mL is adjusted to 12.5 with 1mol / L sodium hydroxide, and the pH is adjusted to 12.5 after standing for 24h , The solution was filtered through a 0.22μm microporous membrane, and the pH valu...

Embodiment 3

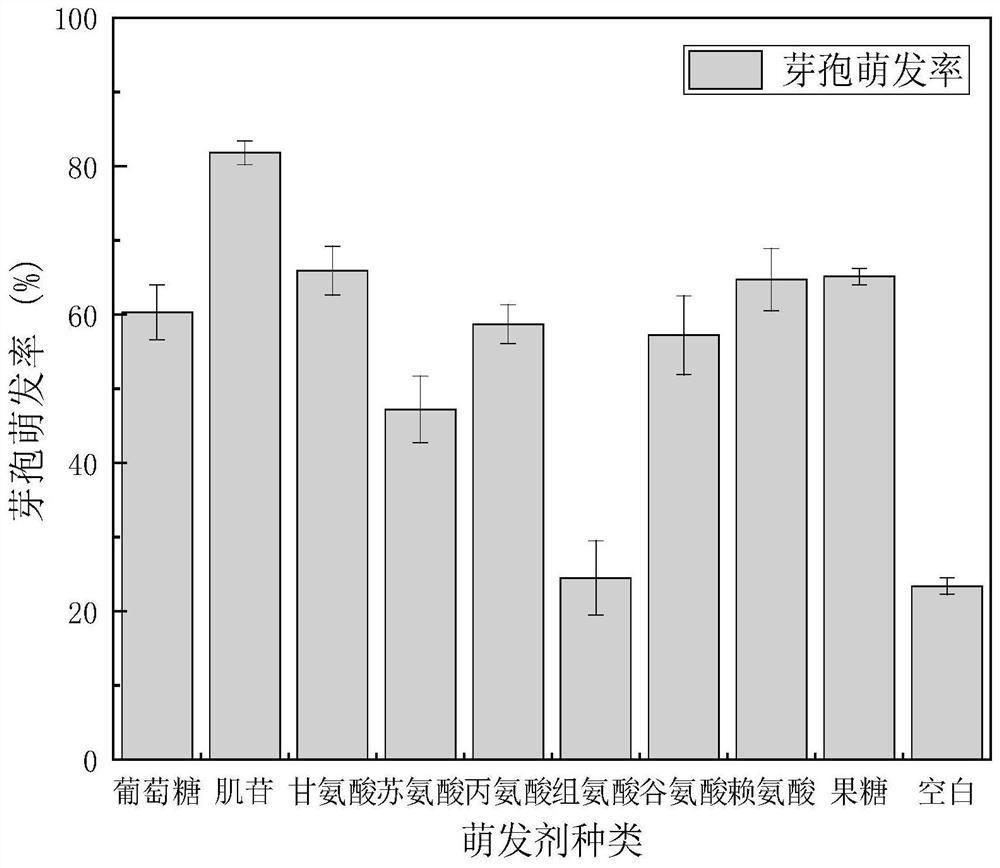

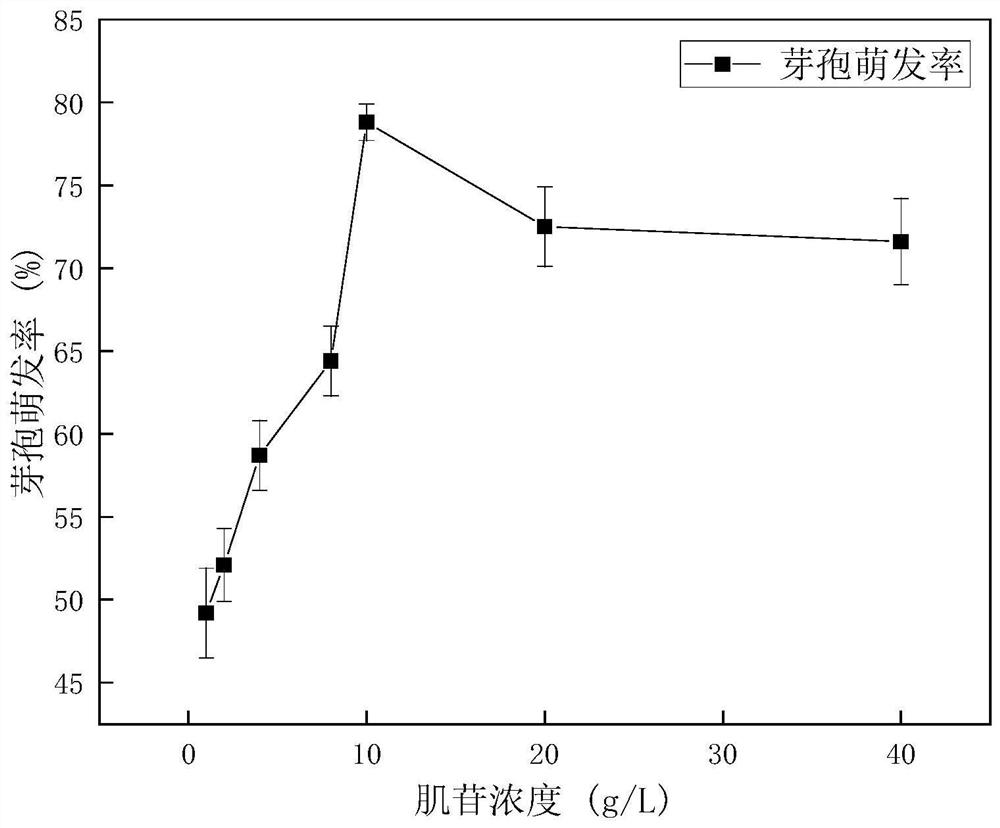

[0048]Example 3: Influence of different inosine concentrations on the spore germination rate of strain ZJB20040

[0049]The strain ZJB20040 was inoculated into a spore fermentation medium with a bottled volume of 200 mL, and placed in a constant temperature culture shaker at 30° C. for shaking culture at 150 r / min for 12 hours. The fermentation broth was centrifuged at 8000r / min for 10min at 4°C to obtain the bacteria. The cells obtained by centrifugation are washed 6-8 times with deionized water to prepare a spore suspension.

[0050]Add glucose, fructose, alanine, glutamic acid, glycine, histidine, lysine, threonine, and inosine to the prepared spore germination basal medium, and make the final concentration all 10g / L, the spore germination basal medium without germination agent is used as a blank control. Take the prepared spore suspension and add it to a 96-well plate containing spore germination medium. The volume ratio of the two is 1:4, and the OD is measured after gently mixing.4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com