Thin film solar cell absorption layer forming method, thin film solar cell and preparation method

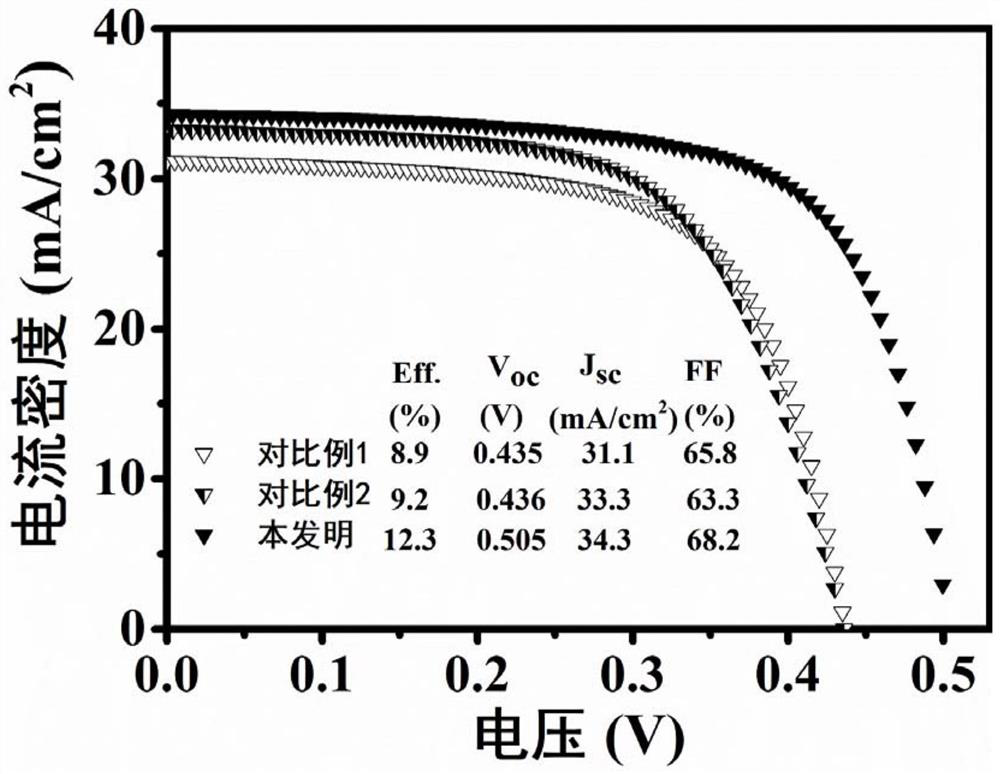

A thin-film solar cell and absorption layer technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of reducing the crystal quality of the absorption layer and affecting the conversion efficiency of the device, so as to improve the photoelectric conversion efficiency and improve the carrier collection efficiency. , the effect of interface recombination reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

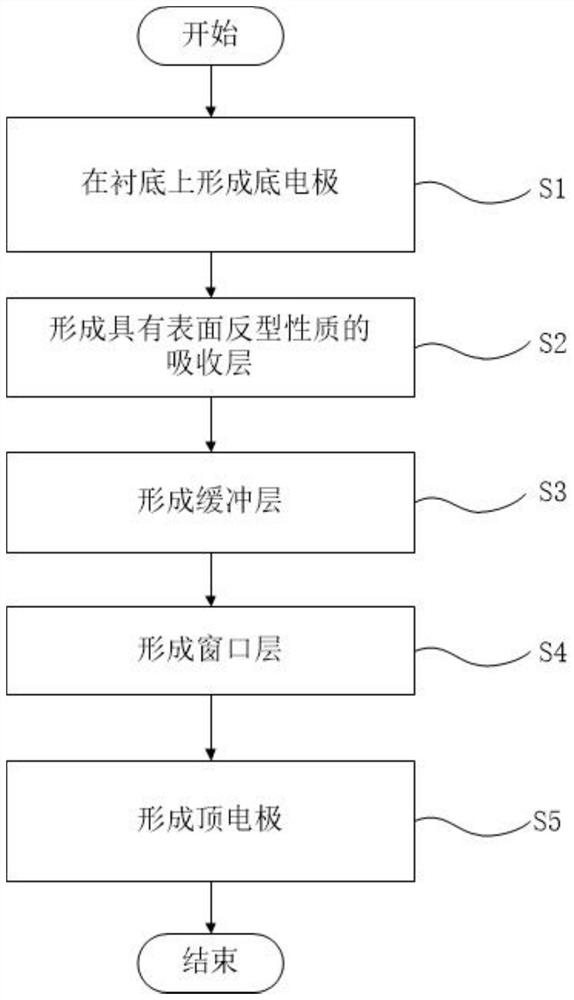

[0029] The method for preparing the thin film solar cell of the present invention will be described in detail below through a specific example. like figure 1 Shown, the preparation method of thin film solar cell of the present invention comprises the following steps:

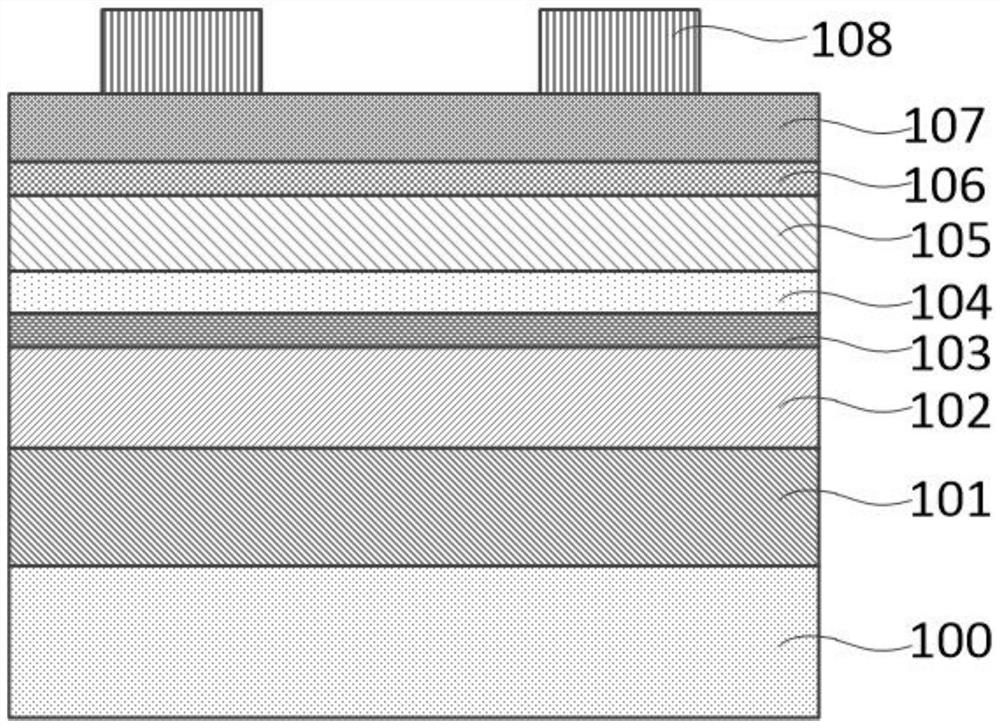

[0030] In the bottom electrode forming step S1 , a Mo metal electrode is prepared on the substrate 100 as the bottom electrode 101 , optionally with a thickness of 1˜5 μm. Wherein, the substrate may also be a flexible substrate or a rigid substrate such as soda-lime glass, sodium-free glass, or quartz glass. The method for preparing the metallic Mo electrode may be magnetron sputtering or evaporation, but is not limited thereto.

[0031] In the absorption layer formation step S2 having surface inversion properties, first, Cu is spin-coated on the bottom electrode 101 2 ZnSnS 4 The precursor solution is then heated and dried on a hot plate at 100-500° C. for 30-300 seconds to promote volatilization of organic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com