Sodium-sulfur battery positive electrode material and preparation method thereof

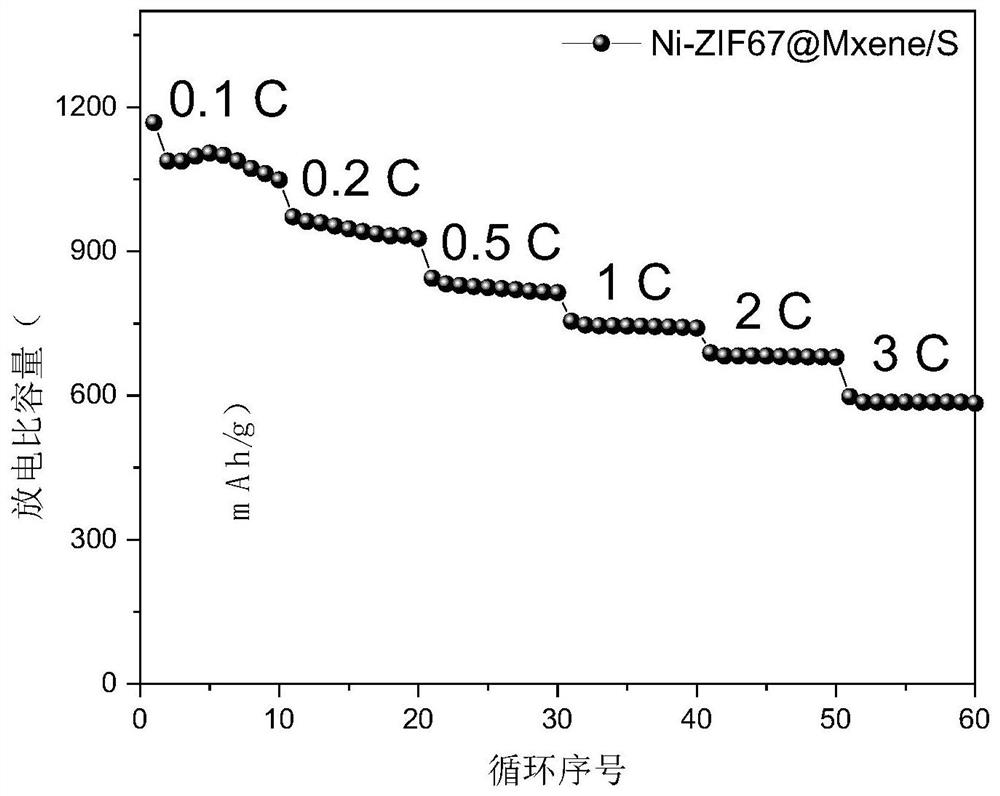

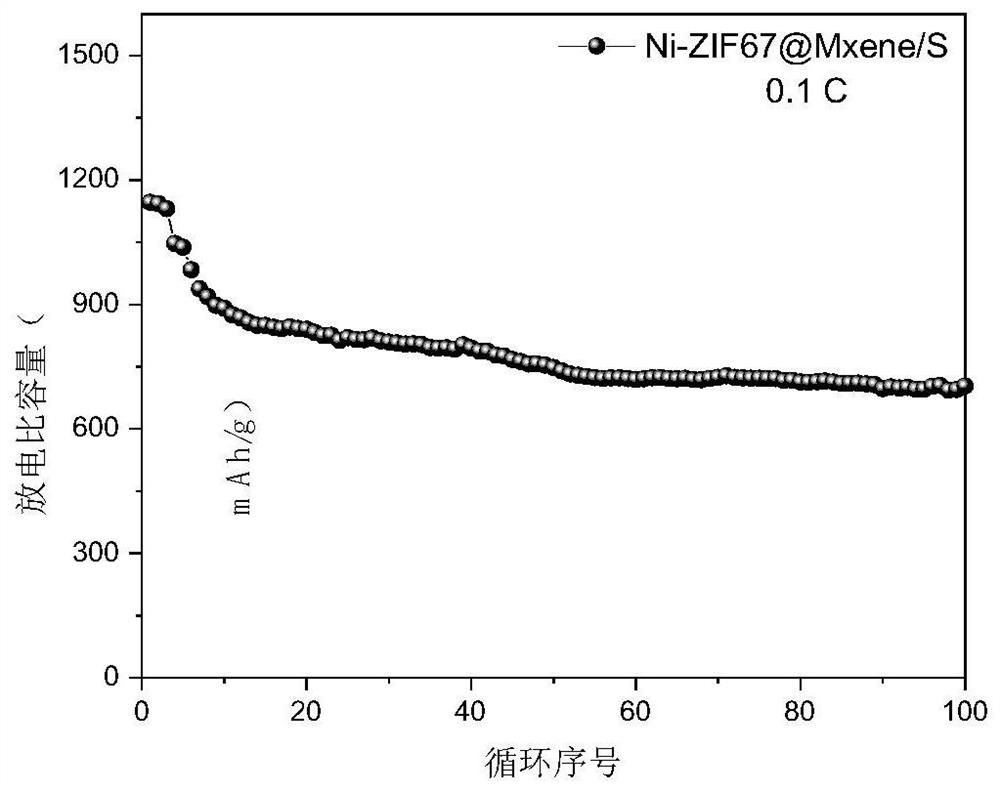

A cathode material, sodium-sulfur battery technology, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of poor rate performance, short cycle life, low utilization rate, etc., achieve high porosity, solve volume expansion, The effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation method of the positive electrode material of the sodium-sulfur battery comprises the following steps:

[0024] (1) Preparation of ZIF67 with a dodecahedral structure: Weigh 1.45g of cobalt nitrate and 1.64g of dimethylimidazole and dissolve them in 125mL of methanol respectively. After the two are completely dissolved, quickly pour the methanol solution of dimethylimidazole into into the methanol solution of cobalt nitrate, fully stirred for 20 minutes, and then stood still for 24 hours; then, after using methanol for centrifugation and washing 3 times, it was incubated at 60 ° C for 12 hours to obtain ZIF67 nanoparticles;

[0025] (2) Preparation of dodecahedral hollow shell material Ni-ZIF67 composed of layered double metal hydroxide: weigh 730mg of nickel nitrate and 300mg of ZIF67 obtained in step (1), dissolve nickel nitrate in 180mL of absolute ethanol, ZIF67 Dissolve in 20mL of absolute ethanol; heat the ethanol solution of nickel nitrate in a rou...

Embodiment 2

[0031] The preparation method of the positive electrode material of the sodium-sulfur battery comprises the following steps:

[0032] (1) Preparation of ZIF67 with a dodecahedral structure: Weigh 1.45g of cobalt nitrate and 1.64g of dimethylimidazole and dissolve them in 125mL of methanol respectively. After the two are completely dissolved, pour the methanol solution of dimethylimidazole into In the methanol solution of cobalt nitrate, fully stir for 20 minutes and then stand still for 24 hours; then use methanol to centrifuge and wash 3 times, and then incubate at 60 ° C for 12 hours to obtain ZIF67 nanoparticles;

[0033] (2) Preparation of dodecahedral hollow shell material Ni-ZIF67 composed of layered double metal hydroxide: weigh 730mg of nickel nitrate and 200mg of ZIF67 obtained in step (1), dissolve nickel nitrate in 180mL of absolute ethanol, ZIF67 Dissolve in 20mL absolute ethanol; heat the ethanol solution of nickel nitrate in a round bottom flask to 60°C, then pou...

Embodiment 3

[0037] The preparation method of the positive electrode material of the sodium-sulfur battery comprises the following steps:

[0038](1) Preparation of ZIF67 with a dodecahedral structure: Weigh 1.45g of cobalt nitrate and 1.64g of dimethylimidazole and dissolve them in 125mL of methanol respectively. After the two are completely dissolved, pour the methanol solution of dimethylimidazole into In the methanol solution of cobalt nitrate, fully stir for 20 minutes and then stand still for 24 hours; then use methanol to centrifuge and wash 3 times, and then incubate at 60 ° C for 12 hours to obtain ZIF67 nanoparticles;

[0039] (2) Preparation of dodecahedral hollow shell material Ni-ZIF67 composed of layered double metal hydroxide: weigh 730mg of nickel nitrate and 400mg of ZIF67 obtained in step (1), dissolve nickel nitrate in 180mL of absolute ethanol, ZIF67 Dissolve in 20mL absolute ethanol; heat the ethanol solution of nickel nitrate in a round bottom flask to 78°C, then pour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com