Building material and preparation method thereof, and aerated concrete block and application thereof

A technology for building materials and raw materials, applied in the fields of aerated concrete blocks, applications, building materials and their preparation, can solve the problems of inability to improve compressive strength, and achieve high compressive strength, reduce pollution, and improve compressive strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of air-entrained concrete block, concrete preparation method is as follows (referring to figure 1 shown):

[0031] 1) Weigh phosphogypsum and add water to mix evenly, then place it in a high-pressure reactor, and then feed liquid nitrogen into the reactor at a rate of 1mL / min until the pressure of the reactor reaches 3MPa, stabilize the pressure for 10min, and then perform ultrasonic and microwave combined treatment 25min, the ultrasonic frequency is 10kHz, the ultrasonic power is 10W, the microwave frequency is 1000MHz, and the microwave power is 10W, dry to obtain modified phosphogypsum;

[0032] 2) Weigh 10 kg of sea sand, 50 kg of fly ash, 10 kg of modified phosphogypsum, 10 kg of Portland cement, 12 kg of limestone powder, 4 kg of diatomaceous earth, 1 kg of desulfurization ash, 0.5 kg of regulator and Water (the amount of water added is based on the moisture content of the air-dried state of the building material is 8-12%), mixed evenly, exhausted by vacuu...

Embodiment 2

[0034] A kind of air-entrained concrete block, concrete preparation method is as follows (referring to figure 1 shown):

[0035] 1) Weigh phosphogypsum and add water to mix evenly, then place it in a high-pressure reactor, and then feed liquid nitrogen into the reactor at a rate of 5mL / min until the pressure of the reactor reaches 6MPa, stabilize the pressure for 15min, and then perform ultrasonic and microwave combined treatment 65min, ultrasonic frequency is 30kHz, ultrasonic power is 80W, microwave frequency is 2500MHz, microwave power is 80W, dry to obtain modified phosphogypsum;

[0036] 2) Weigh 30 kg of sea sand, 70 kg of fly ash, 30 kg of modified phosphogypsum, 30 kg of Portland cement, 25 kg of limestone powder, 10 kg of diatomaceous earth, 5 kg of desulfurization ash, 3.5 kg of regulator and Water (the amount of water added is based on the moisture content of the air-dried state of the building material is 8-12%), mixed evenly, exhausted by vacuum (vacuum degree ma...

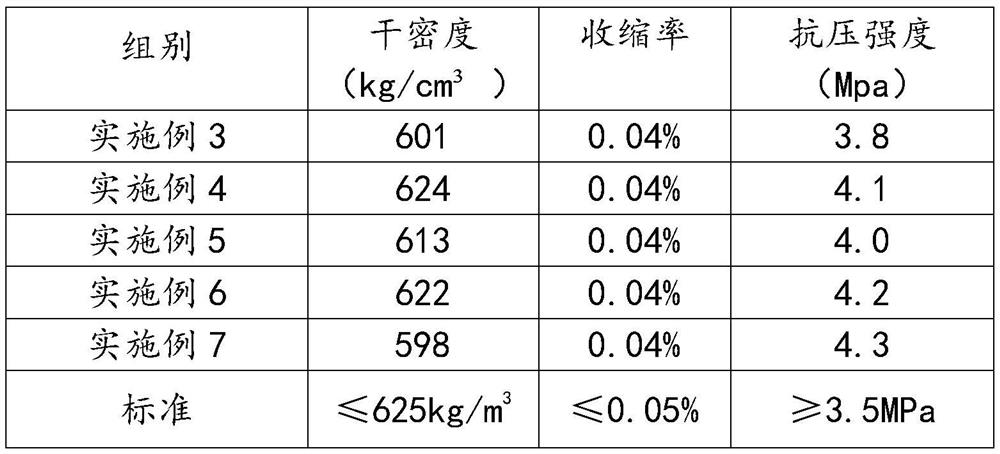

Embodiment 3

[0038]A building material, including the following raw materials: 10 kg of sea sand, 50 kg of fly ash, 10 kg of modified phosphogypsum, 10 kg of Portland cement, 12 kg of limestone powder, 4 kg of diatomaceous earth, and 1 kg of desulfurized ash , 0.002 kg of aluminum powder, 0.001 kg of bubble stabilizer, 0.5 kg of regulator and appropriate amount of water. Wherein, the amount of water added is based on the moisture content of the air-dried state of the building material being 8-12%. The conditioner is prepared by mixing iron tailings sand, sodium silicate and polycarboxylic acid in a weight ratio of 10:1:1. The preparation method of the modified phosphogypsum is to weigh the phosphogypsum, add water and mix it evenly, then place it in a high-pressure reactor, and then feed liquid nitrogen into the reactor at a rate of 3mL / min until the pressure of the reactor reaches 4MPa, and stabilize the pressure. After 12 minutes, ultrasonic and microwave combination treatment was perfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com