Conductive cyclic polyolefin composite material and preparation method thereof

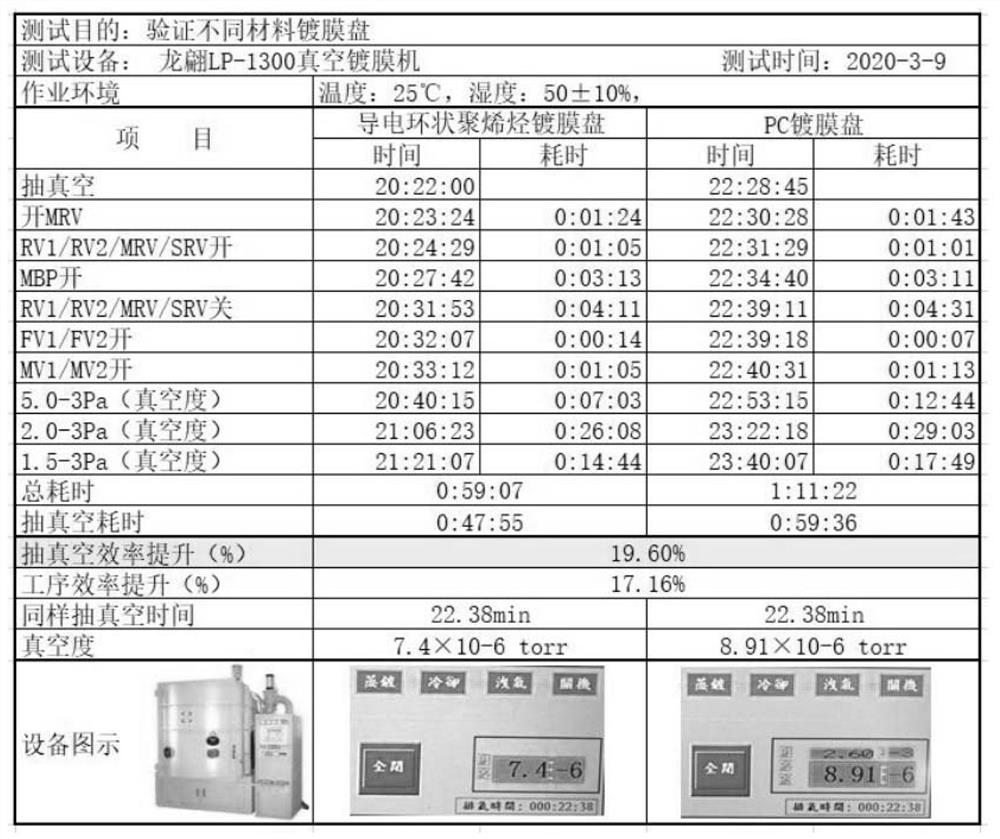

A cyclic polyolefin and composite material technology, applied in the field of coating discs, can solve the problems of lack of electrical conductivity, large internal stress, distortion and deformation, and achieve excellent electrical conductivity and antistatic properties, improve elongation at break, and improve toughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

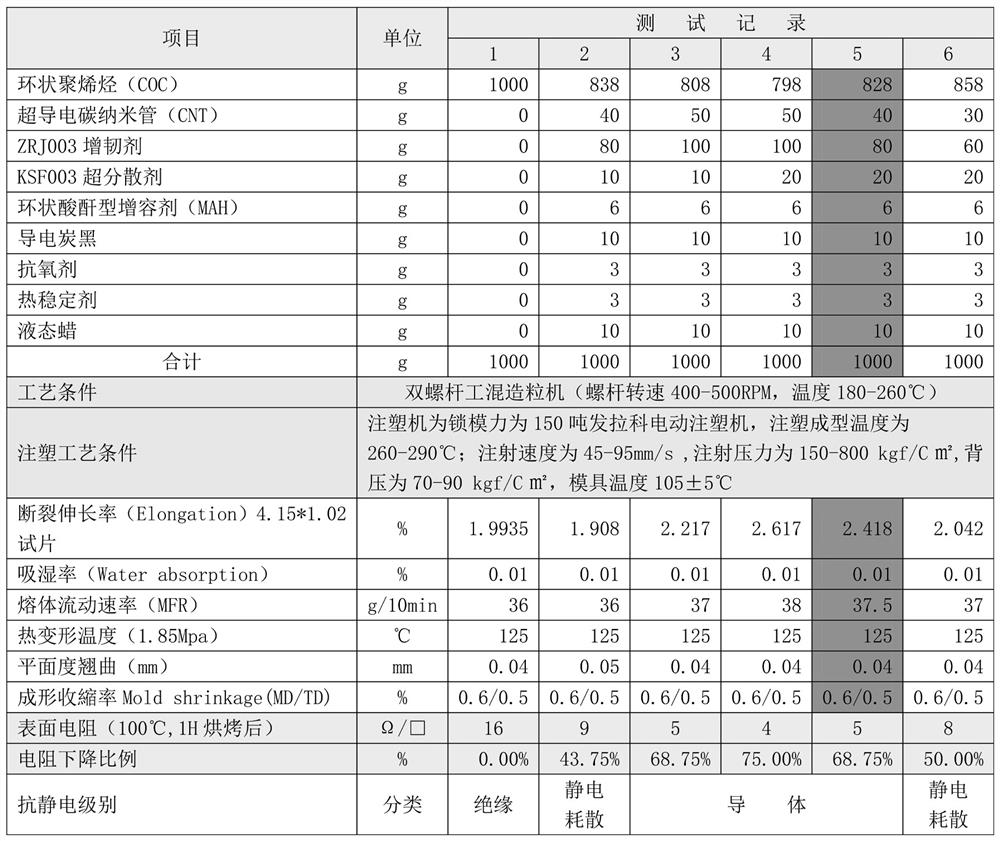

Embodiment 1

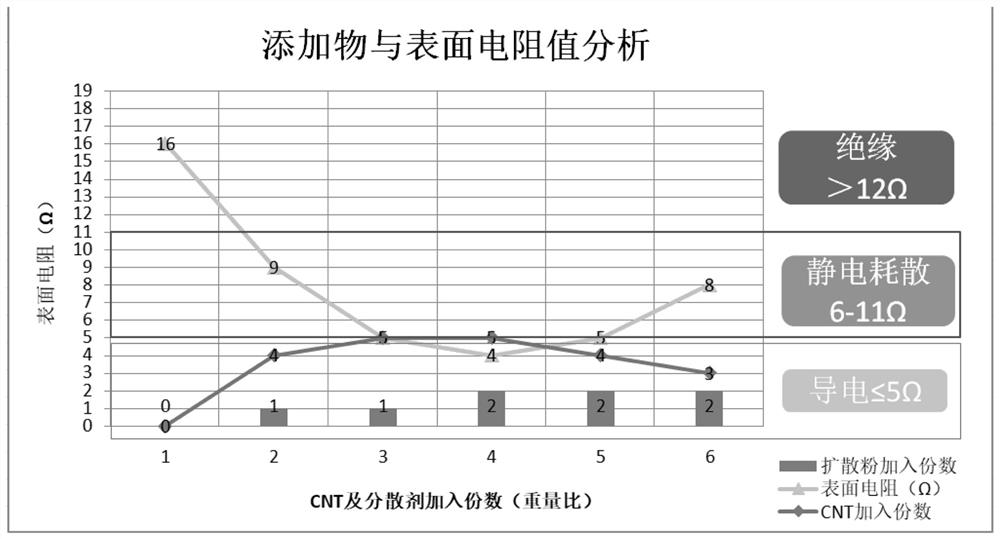

[0036] This example is used as a comparative example, and only 100 parts by weight of cyclic polyolefin (COC) nozzle broken material is prepared through an extruder.

Embodiment 2

[0038] In this embodiment, the formula of the conductive cyclic polyolefin composite material in parts by weight is as follows: 83.8 parts of cyclic polyolefin (COC) nozzle crushing material, 4 parts of superconducting multi-walled carbon nanotubes (CNT), 1 part of conductive carbon black 1 part, 8 parts of polyolefin toughening agent, 1 part of aliphatic ester hyperdispersant, 0.3 part of cyclic anhydride type compatibilizer, 0.3 part of phenolic antioxidant, 0.3 part of calcium stearate heat stabilizer, liquid wax 1 serving.

Embodiment 3

[0040] The formula of the conductive cyclic polyolefin composite material in parts by weight is as follows: 83.8 parts of cyclic polyolefin (COC) nozzle crushing material, 5 parts of superconducting multi-walled carbon nanotubes (CNT), 1 part of conductive carbon black, polyolefin reinforced 10 parts of toughening agent, 1 part of aliphatic ester hyperdispersant, 0.3 part of cyclic anhydride type compatibilizer, 0.3 part of phenolic antioxidant, 0.3 part of calcium stearate heat stabilizer, 1 part of liquid wax.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com