Method for judging shiitake mushroom drying stage based on gas sensor

A technology of gas sensor and discrimination method, which is applied in the direction of instruments, character and pattern recognition, calculation, etc. It can solve the problems of instability, easy production of inferior products, difficult control of drying conditions, and unpleasant smell, so as to save manpower and time, Avoid economic loss, simple effect of pretreatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

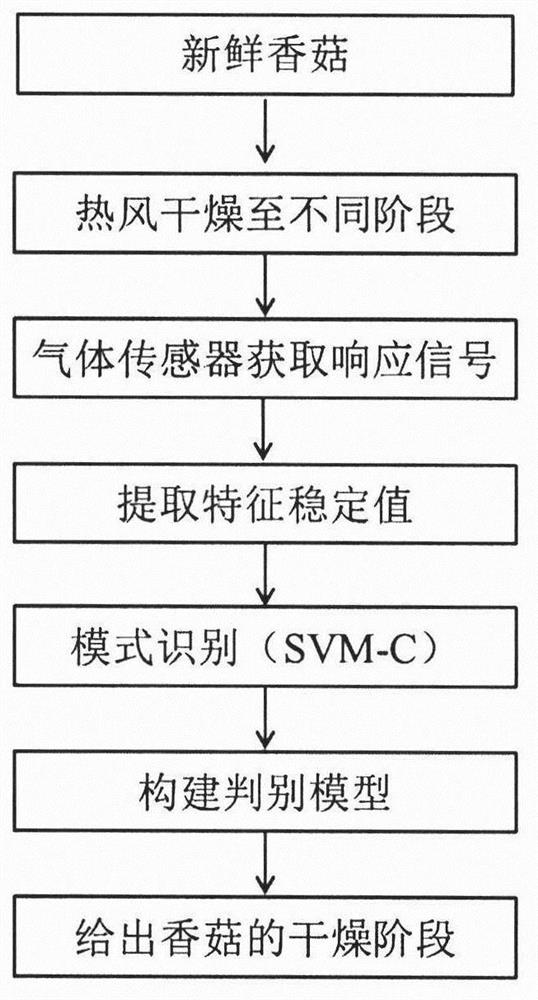

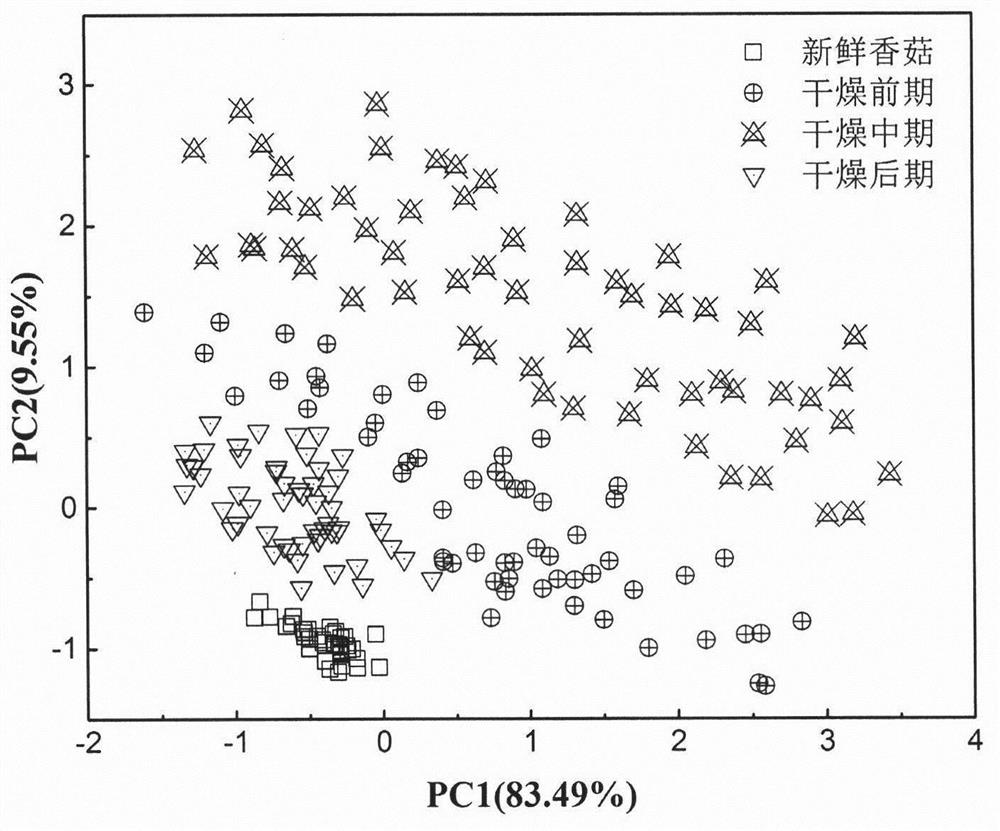

[0019]A method for identifying the drying stage of shiitake mushrooms based on a gas sensor, the specific implementation is as follows:

[0020]1. Test materials

[0021]Select fresh shiitake mushrooms with the same size (the radius of the umbrella cover is about 2.5cm) and the fruit body is intact, and trim the mushroom stems to a length of about 1.0cm, then wash and dry the surface water. Spread 400g mushroom samples flat (one layer) in a 65°C electric heating constant temperature blast drying oven until reaching the end of drying (moisture moisture content <13%), and reaching the end of drying after 8 hours of measurement.

[0022]2. Test equipment

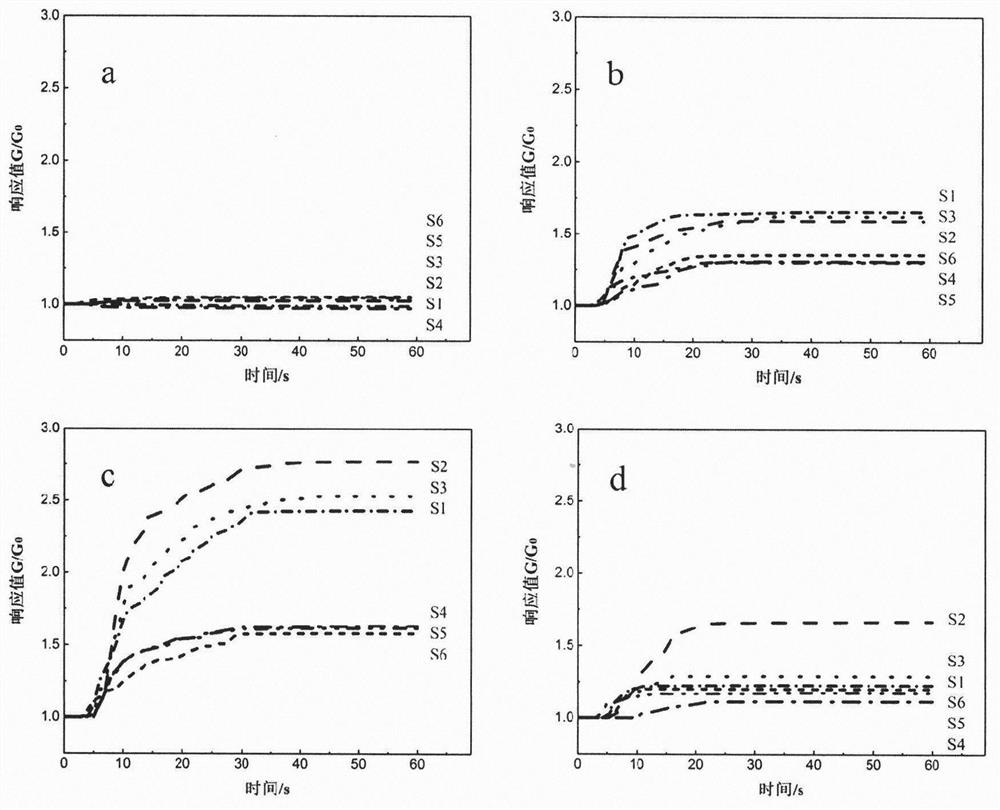

[0023]The electric heating constant temperature blast drying oven model is DGG-9123A, Shanghai Senxin Experimental Instrument Co., Ltd.; the electronic nose used is self-developed, including 6 metal oxide sensors, MQ-136, namely S1, sensitive to hydrogen sulfide , The sensitivity is 1-200ppm; TGS2602, namely S2, is sensitive to organic volatile ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com