Biochemical oxygen demand microfluidic detection equipment and biochemical oxygen demand microfluidic detection method based on bacterial microcapsules

A biochemical oxygen demand and detection equipment technology, applied in the direction of testing water, measuring devices, material inspection products, etc., can solve the problems of harsh application conditions, poor repeatability, and short microbial film life, and achieve short life, stable performance, Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation of embodiment 1 bacillus subtilis microcapsules

[0035] The Bacillus subtilis microcapsules are prepared by a flow focusing method of a microfluidic chip. Specifically, it includes: first culture Bacillus subtilis at 30°C and 170r / min for 24h, then centrifuge at 4°C and 3000r / min for 15 minutes to collect the bacteria, wash twice with phosphate buffer to prepare a 20mg / mL bacterial suspension. Then sodium alginate (concentration can be 4-8%, specifically 4%), polyvinyl alcohol (concentration can be 8-15%, specifically 10%) solution is mixed with 9: 1 ratio, the mixed solution obtained and Equal volumes of bacterial suspensions were mixed, and the bacteria-containing mixed solution obtained again was mixed with an equal volume of 100mM Ca-EDTA as a dispersed phase, wherein sodium alginate and polyvinyl alcohol were used as wall materials, mechanically Higher strength is more conducive to the stability of bacterial microspheres. Next, fluorinated oil FC...

Embodiment 2

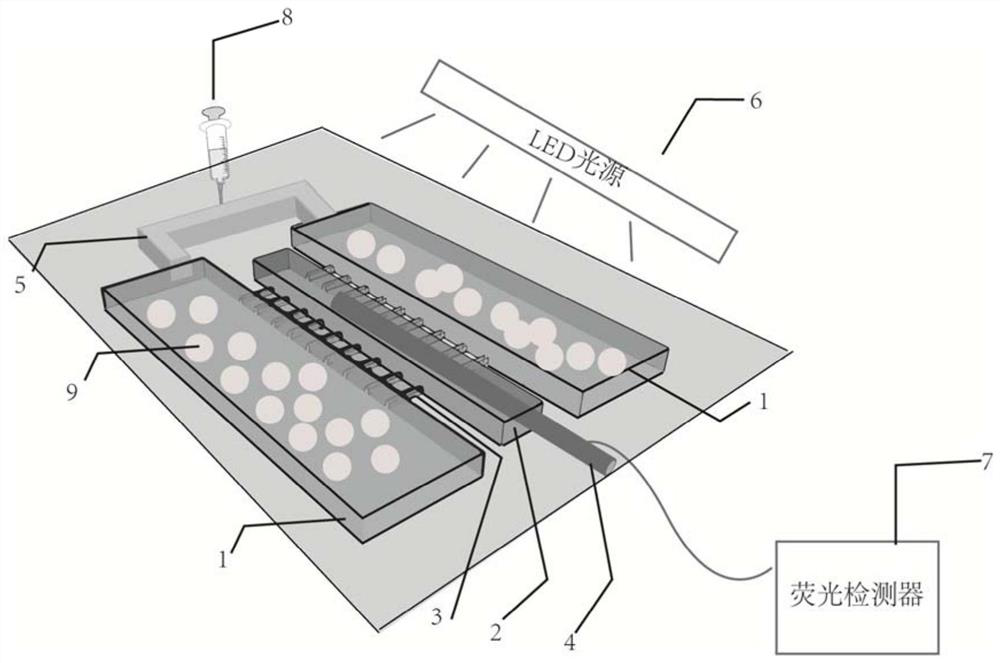

[0036] The design of the multi-channel microfluidic chip of embodiment 2 Bacillus subtilis microcapsules

[0037] First, design the specific structure of the multi-channel microfluidic chip; among them, the bottom plate of the chip is made of glass, and each channel is made of polydimethoxysiloxane, polyacrylic acid, etc. Specific structural design: the multi-channel microfluidic chip is set as three main channels, including: storage channel 1 on the left, detection channel 2 in the middle, and storage channel 1 on the right, wherein two storage channels 1 The length is 40mm and the width is 25mm; the detection channel 3 is 40mm long and 50mm wide, and the specific dimensions of the detection channel 2 and the storage channel 1 are sufficient to accommodate enough liquid and optical fiber probes; the height of the storage channel 1 and the detection channel 2 is 800 μm . The storage channel 1 and the detection channel 2 are connected through a thin connection channel 3, the h...

Embodiment 3

[0039] Embodiment 3 The design of the porous fiber optic probe 6 and the installation of the detection equipment

[0040] First, the commercially available porous optical fiber was washed and soaked with 0.1M NaOH for 2 hours, and then the modification sol was inhaled under the condition of 0.08 MPa, that is, after standing at room temperature for 2 hours, the modification was completed, washed with water, and dried for later use. Wherein, the preparation method of the modified sol is: mix 1mg[Ru(dpp) 3 ]Cl 2 Added to 7.5 mL mixed solution (22.7% ethyl orthosilicate, 22.7% Octyl-triEOS, 50% ethanol, 8% HCl).

[0041] Then, take out the multi-channel microfluidic chip and activate it for 16 hours, insert one end of the modified porous fiber optic probe 4 into the detection channel 2, and connect the unmodified end to the fluorescence detector 7 to read the stored value. Wherein, the end of the detection channel, that is, the insertion end of the porous optical fiber probe, is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com