Monatomic catalyst as well as preparation method and application thereof

A catalyst and atomic technology, which is applied in the field of single-atom catalysts and their preparation, can solve the problems of limited single-atom species, and achieve the effects of enhancing the catalytic activity of nitrogen fixation, improving nitrogen fixation performance, and improving nitrogen fixation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] An aspect of the embodiments of the present invention provides a method for preparing a single-atom catalyst, which includes:

[0027] Provide nitrogen- and carbon-rich organics as precursors;

[0028] The nitrogen- and carbon-rich organic matter is subjected to a high-temperature polymerization reaction to obtain a bulk carbon nitride material, which is then exfoliated to obtain an ultra-thin carbon nitride nanosheet (g-C 3 N 4 ultrathin nanosheets);

[0029] The hydrothermal reaction system comprising the carbon nitride ultrathin nanosheets, the transition metal source and the solvent is subjected to a hydrothermal reaction to obtain a transition metal oxide / carbon nitride composite material (transition metal oxide / g-C 3 N 4 composite materials);

[0030] And, the transition metal oxide / carbon nitride composite material is calcined and etched to obtain a single-atom catalyst.

[0031] In some more specific embodiments, the nitrogen- and carbon-rich organic matter...

Embodiment 1

[0086] Weigh a certain amount of melamine and place it in a 30ml quartz crucible, and place the crucible in a muffle furnace at 2°C min -1 The heating rate was increased to 550°C and kept at this temperature for 2 hours to obtain a yellow lump; then the yellow lump was ground and refined, and ultrasonically dispersed with water for 16 hours until the solution turned milky white, filtered, dried and Collect CN ultra-thin nanosheets;

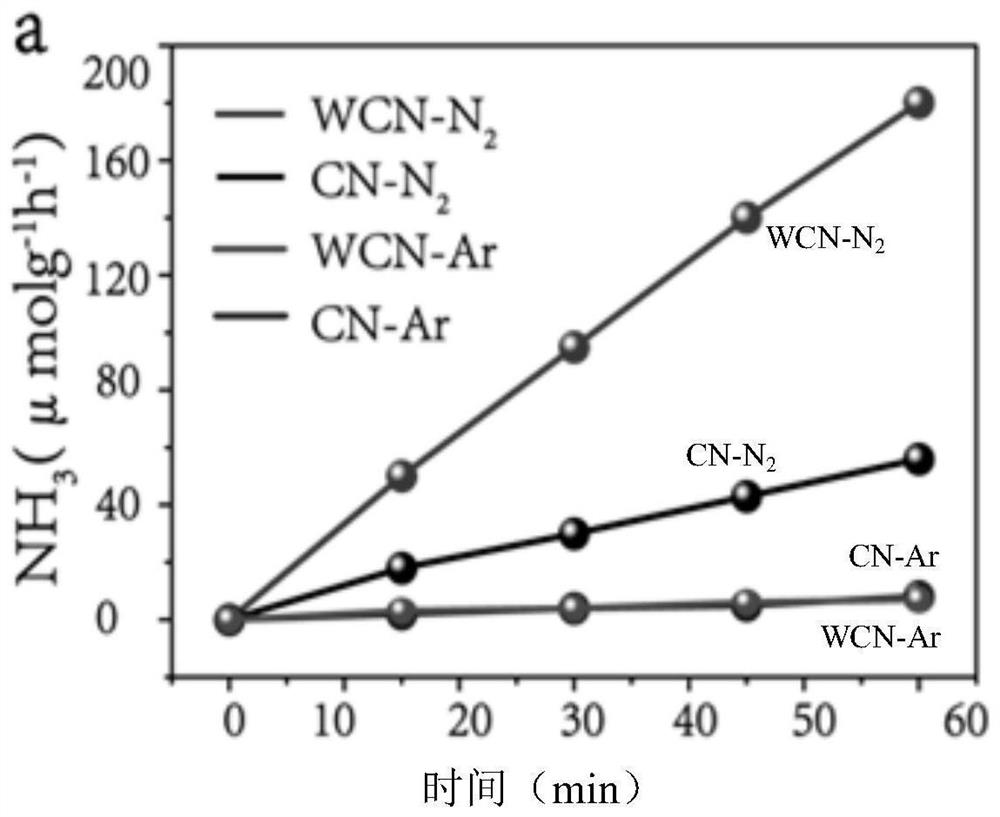

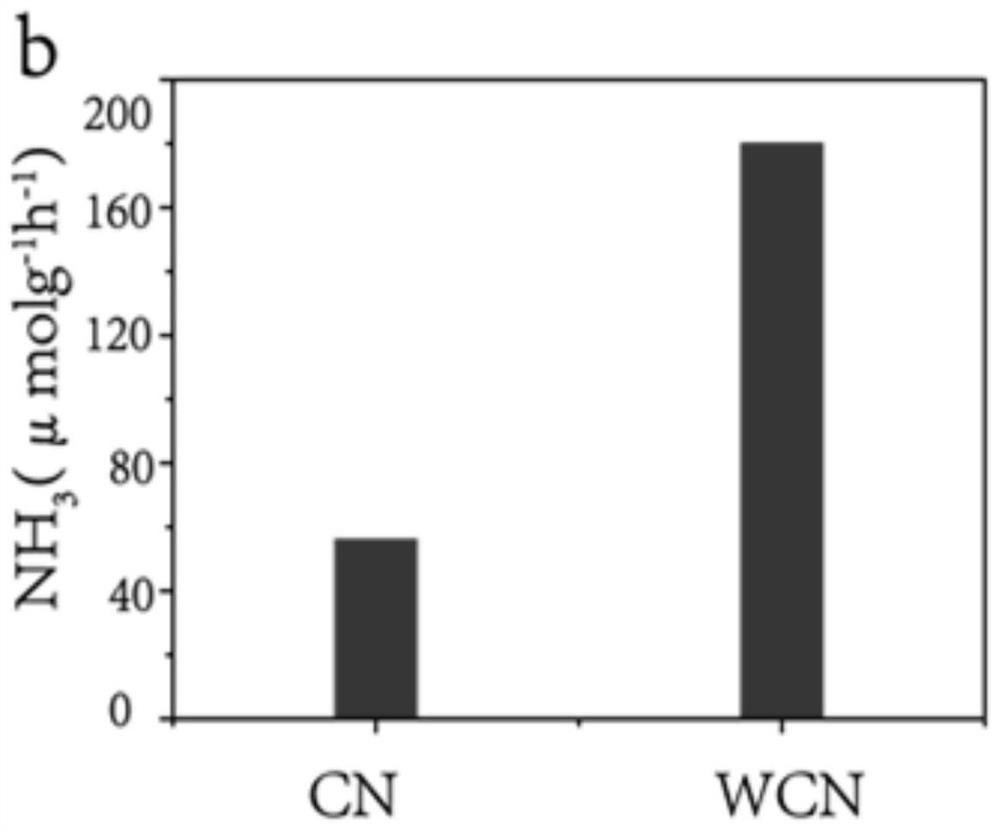

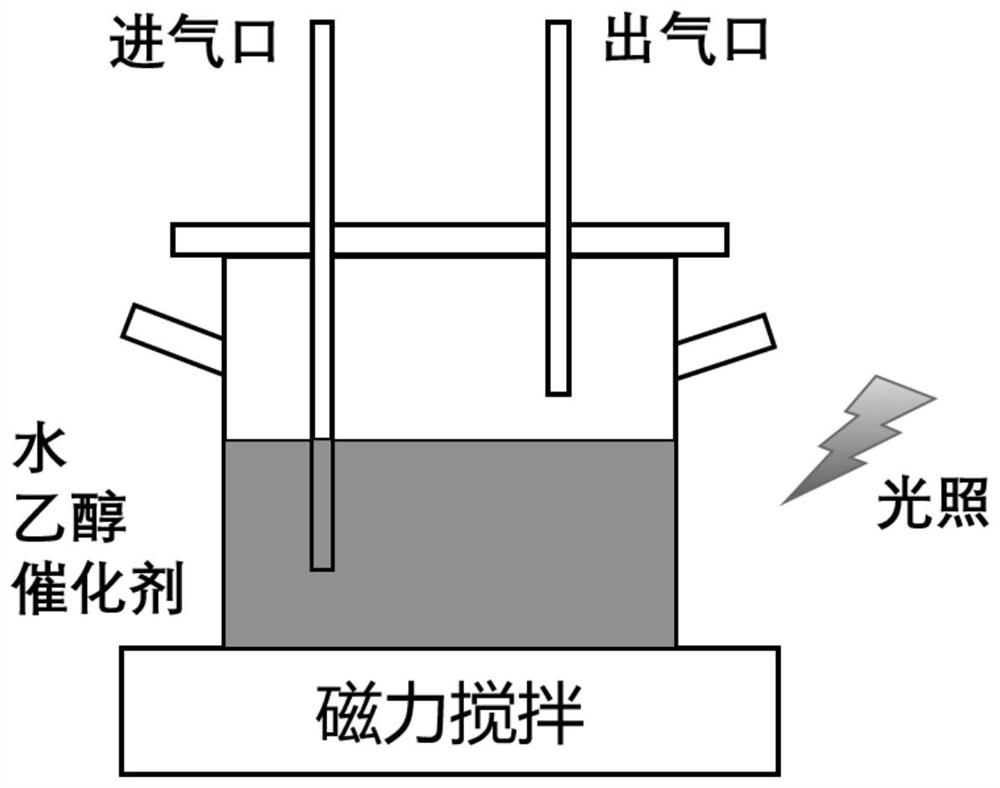

[0087] Weigh 50mg of CN ultra-thin nanosheets and place them in a beaker, add 40ml of deionized water and 10ml of absolute ethanol, ultrasonically disperse in an ultrasonic cleaner for 2h, then transfer to a photocatalytic reaction vessel, seal the reaction vessel and place it in The solution was continuously stirred on a magnetic stirrer, and both ends of the reactor were connected to circulating water cooling to maintain 20°C, and then 60ml·min -1 The flow rate is continuously fed with N with a purity of 99.9% 2 , 1h later, turn on the 300W Xe...

Embodiment 2

[0089] Weigh a certain amount of melamine and place it in a 30ml quartz crucible, and place the crucible in a muffle furnace at 2°C min -1 The heating rate was increased to 550°C and kept at this temperature for 2 hours to obtain a yellow lump; then the yellow lump was ground and refined, and ultrasonically dispersed with water for 16 hours until the solution turned milky white, filtered, dried and Collect CN ultra-thin nanosheets;

[0090] Weigh 50mg of CN ultra-thin nanosheets and place them in a beaker, add 40ml of deionized water and 10ml of absolute ethanol, ultrasonically disperse in an ultrasonic cleaner for 2h, then transfer to a photocatalytic reaction vessel, seal the reaction vessel and place it in The solution was continuously stirred on a magnetic stirrer, and both ends of the reactor were connected to circulating water cooling to maintain 20°C, and then 60ml·min -1 The flow rate was continuously fed with Ar with a purity of 99.9%. After 1 hour, a 300W Xe lamp wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com